Shenzhen-based 3D printer manufacturer Anycubic recently announced a new addition to its desktop FDM 3D printer portfolio, the Kobra 2 Max.

Offering notable upgrades from the previous Kobra 2 model, the Kobra 2 Max is optimized for high-speed, large-scale desktop 3D printing at an affordable price. Anycubic’s new 3D printer also stands out thanks to upgraded bed leveling, extrusion, and cooling systems, as well as its PID calibration and vibration compensation.

This article will highlight our first impressions of the Kobra 2 Max, whilst outlining the key features and selling points of Anycubic’s latest high-speed 3D printer.

The Kobra 2 Max is available to order for $549 through the official Anycubic online store.

Key features of the Anycubic Kobra 2 Max

Central to the Kobra 2 Max is its speed. According to Anycubic, the Kobra 2 Max’s 500mm/s maximum 3D printing speed and 10,000mm/s² acceleration is 10x faster than most mainstream FDM 3D printers on the market. Indeed, the Kobra 2 Max’s recommended 3D printing speeds of 300mm/s can reportedly fabricate a 3D Benchy in just 18 minutes, 83% quicker than other 50mm/s systems.

High-speed 3D printing is aided by a high-performance Cortex-A7 1.2GHz processor. This offers strong computing power for fast calculations, command execution, and motor control.

Anycubic’s new 3D printer is also notable for its substantial 500 x 420 x 420 mm build volume. With the Kobra 2 Max, users can produce models with a volume of up to 88 liters in a single 3D print. This expanded 3D print size allows users to explore more complex 3D prints, and larger projects not possible on smaller desktop offerings.

The Kobra 2 Max also offers connectivity to the new Anycubic APP. This enables remote connectivity, allowing users to view the 3D printer’s status in real-time. Upcoming updates are also set to enable online slicing and 3D printing, real-time video monitoring and time-lapse photography, remote control and management, and an open model library function module.

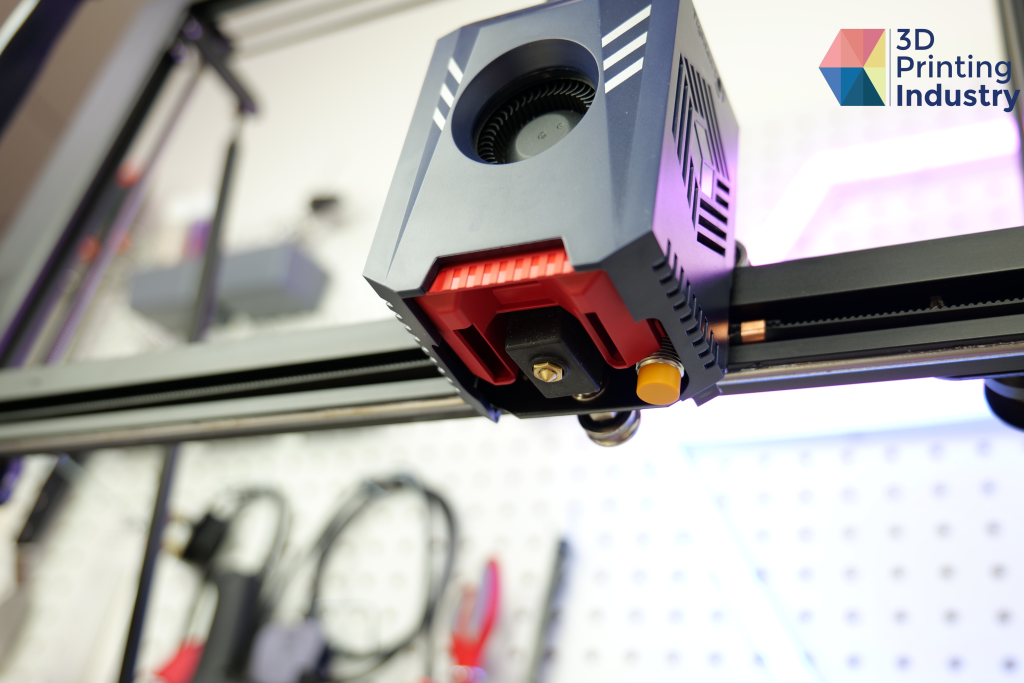

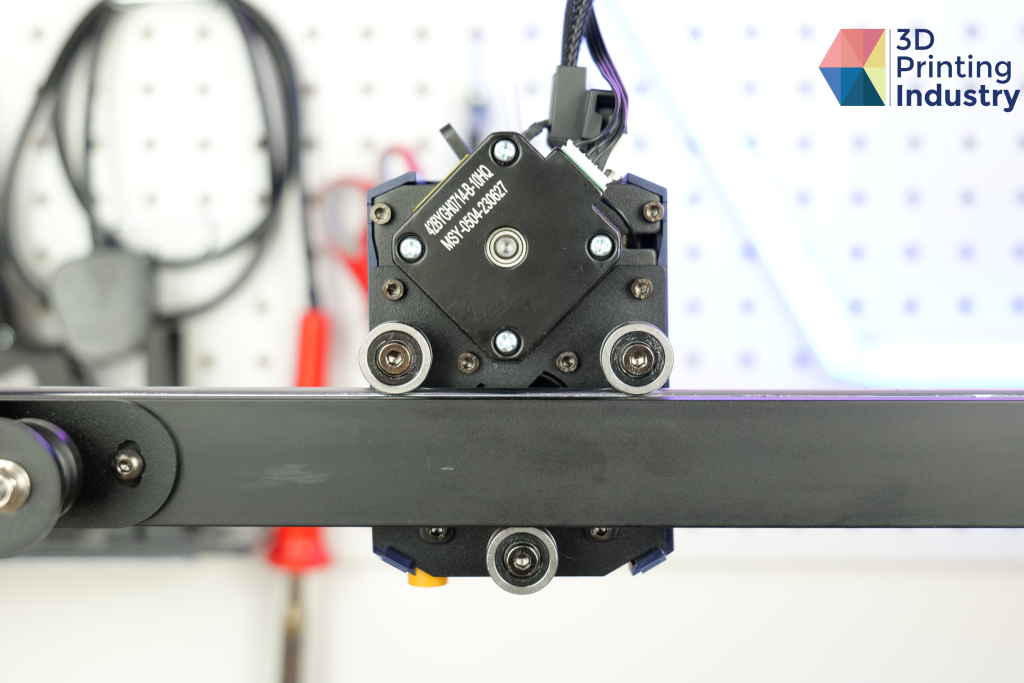

The Kobra 2 Max employs a new direct drive extruder coupled with a dual-motor dual-z-axis motion structure. This optimizes the ability of the 3D printer to convey materials efficiently and accurately. Efficient cooling is also ensured by the 3D printer’s 7,000 rpm/min high-speed cooling fan, which can be quite loud during 3D printing. The Kobra 2 Max also supports a wide range of materials, allowing users to 3D print with PLA, ABS, PETG, and TPU.

First impressions

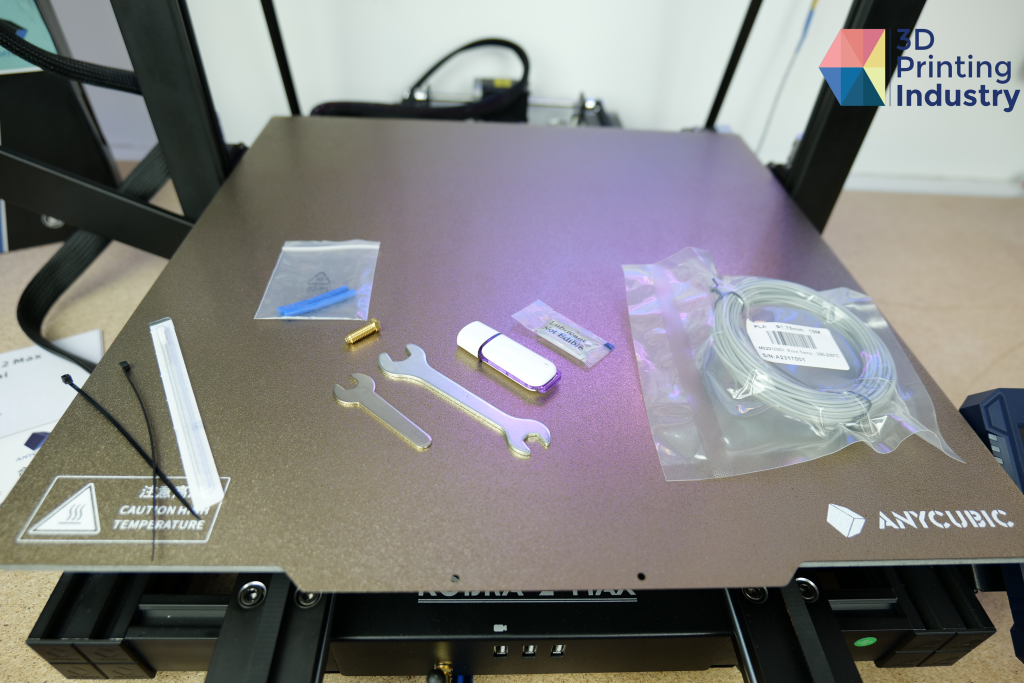

Out of the box, we were largely impressed with the Kobra 2 Max. The 3D printer incorporates a study, full metal frame which supports high-speed 3D printing. With nice overall build quality, the Kobra 2 Max is quite a large open system which perhaps looks less tidy than other fully-enclosed systems. However, given the 3D printers’ affordable price, Anycubic’s new 3D printer offers good value for money.

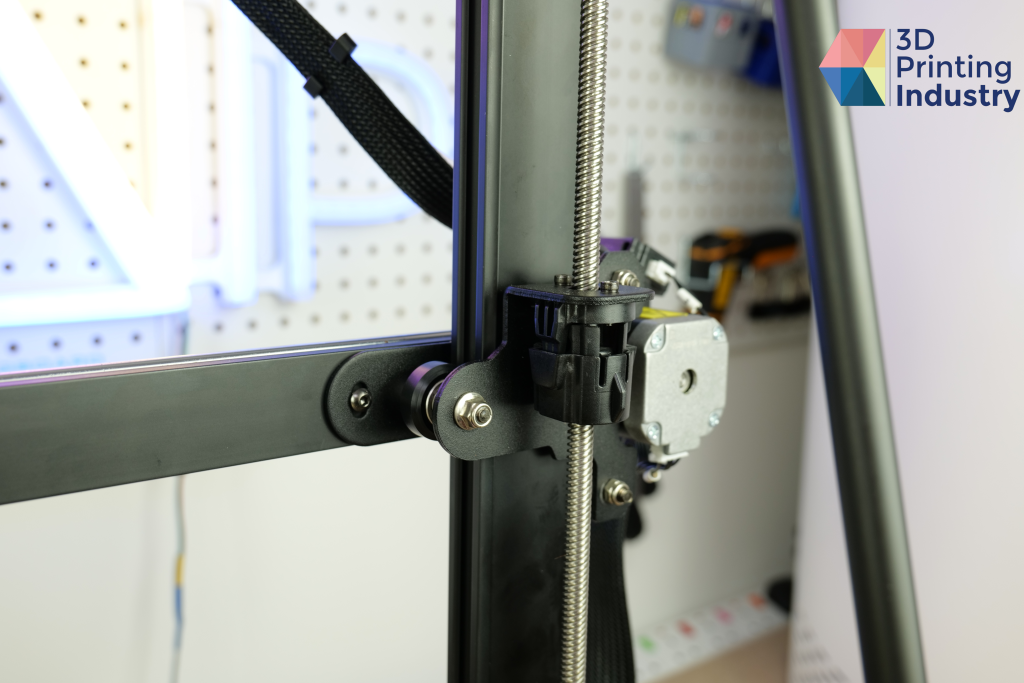

A double motor double Z-axis is included in the Kobra 2 Max, which also possesses double metal spindles and SG15 bearings for high-quality, high-speed extruder movement.

Optimized for ease of use, the Kobra 2 max’s user interface is intuitive and easy to navigate. The 4.3-inch full-color touch-screen interface offers straightforward control and provides responsive functionality.

Our team has been particularly impressed with the Kobra 2 Max’s ‘Vibration Compensation’ and PID calibration. With just one click, the ‘Vibration Compensation’ feature provides resonance frequency detection on the X/Y axis, eliminating vertical and bracket lines for 3D print stability. ‘Flow Control’ is also offered, compensating for retraction and refilling, ensuring uniform and detailed results.

The addition of a smart Z-axis offset into the Kobra 2 Max’s automatic bed leveling system is also a nice touch. This allows the 3D printer to compensate for Z-axis offset while supporting custom Z-axis compensation values. A designated inductive sensor is incorporated for the automatic bed leveling process.

The spring steel magnetic build plate is flexible, and allows for easy part removal. However, we believe this could be improved by the addition of grippers to further secure the build plate during 3D printing.

One small detail that has stood out to us is the designated extruder cleaning pad. Before each 3D print, the extruder is wiped against a small cleaning square located above the top right corner of the build plate, removing any unwanted residue. We see this as an elegant solution to a common 3D printing problem.

Technical specifications

| 3D Printing Technology | FDM |

| Physical Dimensions | 740 x 735 x 640 mm |

| Weight | 21kg |

| Build volume | 500 x 420 x 420 mm / 88L |

| 3D Printing Speed | 500mm/s (Maximum)300mm/s (Typical) |

| X/Y-axis | Double Metal Spindle |

| Z-axis | Double Motor Double Z-axis |

| X/Y-axis Belt Tensioner | Included |

| Build Plate | PEl Magnetic Spring Steel |

| Hotbed Temperature | ≤194F/90°C |

| Cooling Fan RPM | 7000rpm/min |

| Compatible Materials | PLA/ABS/PETG/TPU |

| Bed Leveling | New Anycubic LeviQ 2.0 Automatic Leveling System (49-point) |

| Extruder | Anycubic Self-Developed Direct Extruder + Double Gears |

| Control Panel | 4.3″ LCD Touch-Control Screen |

| Data Input | USB ports x 3 |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the new Kobra 2 Max from Anycubic. Photo by 3D Printing Industry.