3YOURMIND, German based software developers, has released a new feature intended to address one of the most common barriers to widespread adoption of additive manufacturing – the time taken to understand a new technology.

Surveys and interviews conducted by 3D Printing Industry frequently identify a skills and knowledge gap that prevents organisations from adopting industrial 3D printing. To address this issue 3YOURMIND has developed a Use Case Screening tool.

This new feature extends the developers AM Part Identifier tool and is designed to assist enterprises in both identifying parts that are suitable for additive manufacturing and, more importantly, whether there is a business case for making these parts using 3D printing.

Dominik Lindenberger, Product Manager AM Part Identifier at 3YOURMIND explains, “In recent customer tests we’ve been able to identify AM-suitable parts that represent production savings of up to 90% their original costs when compared to conventional manufacturing.”

The tool was developed by 3YOURMIND engineers to focus the time spent by highly skilled specialists. Use of the AM Part Identifier (AMPI) can free up what is often a scarce resource at many companies – the time of an engineer.

“AMPI’s most valuable contribution, however, is the fact that AMPI empowers your entire team to find AM use cases,” says Lindenberger.

By analyzing the work performed by engineers, 3YOURMIND has developed a tool, “that can pre-evaluate parts. With the aim of making the expert’s job simpler and faster we researched for alternatives to manual and individual checks of full inventories.”

3YOURMIND says that the AMPI has already started to generate an impact in the overall amount of parts made with additive manufacturing. This is not only benefiting leading companies with their own AM capacities, including European transportation companies, but also businesses that outsource their 3D printing production.

A range of users can benefit from the AMPI tool. These include employees, who are often the most familiar with components but may not have the knowledge to identify parts suitable for AM, designers who can use the tool to assist in design for additive manufacturing and purchasing departments who can make use of the AMPI tool to improve an enterprises bottom line.

How does it work

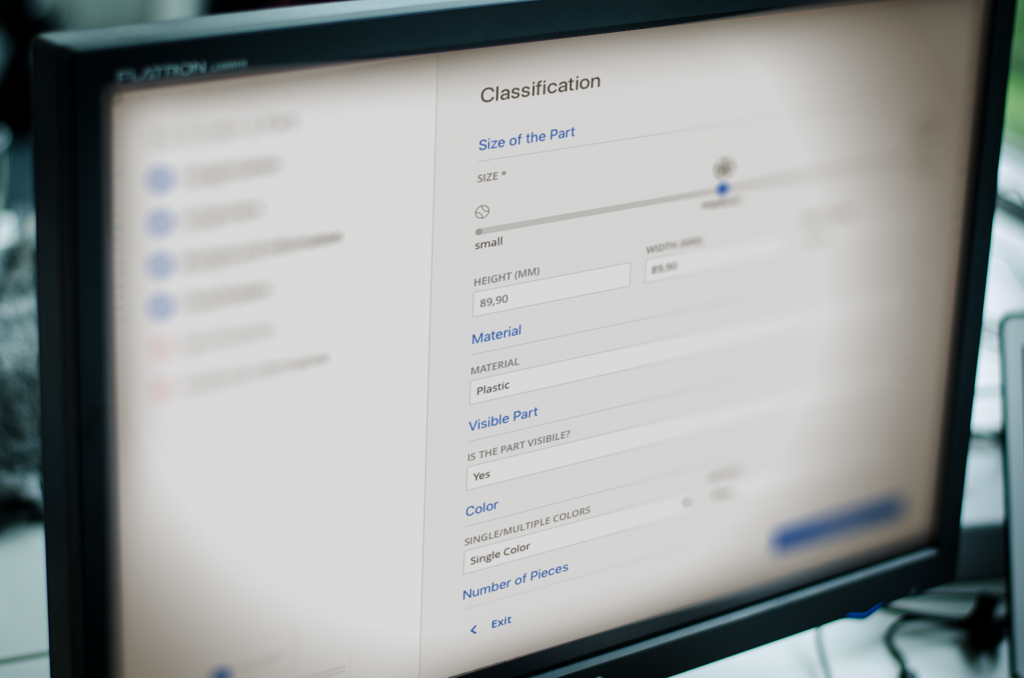

The Use Case Screening tool was developed by 3D printing experts after defining what is the crucial information and criteria required for part evaluation. In order to enable experts to make an informed decision on which business cases have an actual AM potential they designed an easy-to-follow, step by step, information input process enabling anyone without prior AM knowledge to use it.

Part Submission

When submitting a new part for analysis, employees need to enter the following information: area of utilization, part size, material, tolerances, and whether the component is required for part/process qualification among other. Based on data the part will be submitted to evaluation on its economic and technical feasibility for additive manufacturing.

The Evaluation

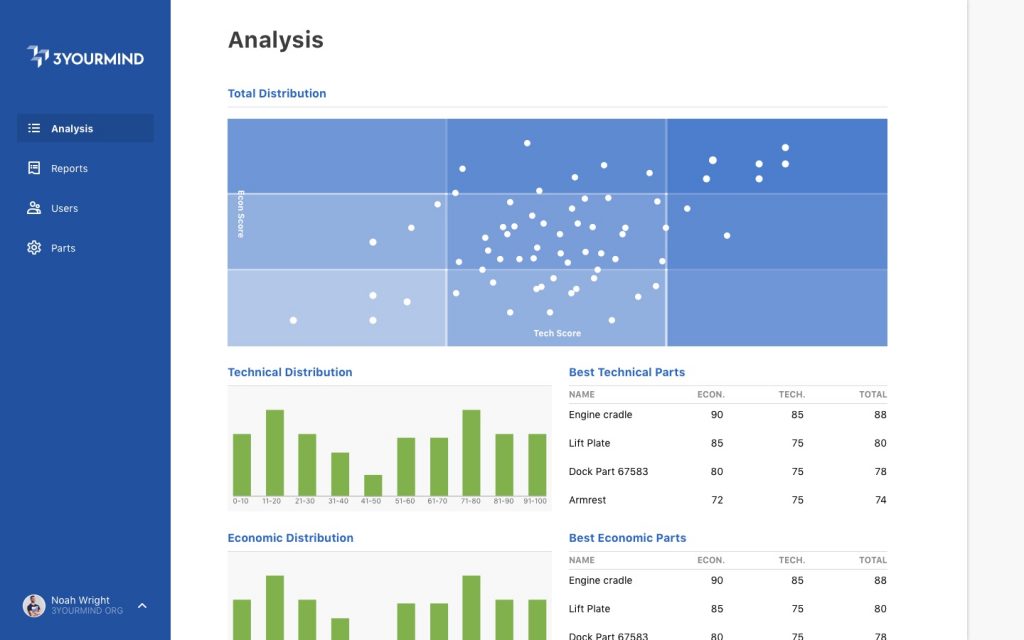

A report is generated in a matter of seconds after the employee makes the final submission. The graphic above represents the scoring of the part and its suitability for AM, suggesting the best use case being located in the top right quadrant.

At this stage the experts can take over. Using the report enables them, with just a glance, to select from the pre-evaluated parts, those components to focus on and bring into AM production. If the parts results are “approved”, they can shortly after be implemented into the 3D printing production workflow, and companies, as well as their customers can begin making use of the benefits of additive manufacturing.

The Evaluation

A report is generated in a matter of seconds after the employee makes the final submission. The graphic above represents the scoring of the part and its suitability for AM, suggesting the best use case being located in the top right quadrant.

At this stage the experts can take over. Using the report enables them, with just a glance, to select from the pre-evaluated parts, those components to focus on and bring into AM production. If the parts results are “approved”, they can shortly after be implemented into the 3D printing production workflow, and companies, as well as their customers can begin making use of the benefits of additive manufacturing.

The value of the pre-evaluation lies on the prioritization of parts to focus on that more likely will represent cost savings and quality increases for the company as a whole. Identifying and qualifying parts that are good business cases for AM isn’t a challenge exclusively to companies that already are utilizing additive manufacturing, but also for those businesses that are considering it, or have recently started to implement it.

This week visitors to the TCT Show in Birmingham UK will be able to learn more about the AMPI directly from 3YOURMIND who will be exhibiting at stand V32.

You can learn more about 3YOURMIND’s AM Part Identifier here.

Featured image shows AMPI Screening before order. Photo via 3YOURMIND.