Nefilatek, a Montreal-based startup specializing in manufacturing recycled filament, has developed 3D printing filaments made from 100% recycled plastic.

The company runs a Kickstarter page, where early adopters can choose between two types of filaments: Nefila HIPS (High Impact Polystyrene) Black, and Nefila PC (Polycarbonate), which comes with reusable spool supports and eco-friendly packaging. With its new filaments, Nefilatek is aiming to provide a “safe alternative solution for makers, designers and manufacturers” that cuts down on the amount of plastic used and wasted in 3D printing.

Reducing the environmental impact of 3D printing

Nefilatek was founded in 2018 by two mechanical engineering students, both whom admired the capabilities of 3D printing to allow inventors, product designers and manufacturers to bring their products into market at increased speed, but were disillusioned by the environmental impact left by the technology. They formed the company in order to combat the large plastic usage of the 3D printing industry, a material that is a major environmental pollutant.

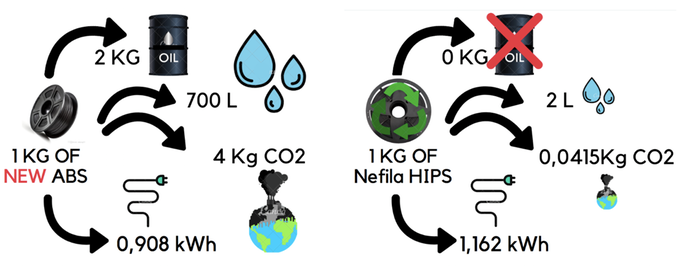

Nefilatek claims that the annual plastic consumption from the 3D printing industry amounts to an estimated 30 million pounds, with a projected 250 million pounds by 2020. Currently, it is also estimated, according to the company, that the production of 3D printing plastics will result in the consumption of 1.4 million barrels of oil, which will generate over 800 million pounds of carbon emissions annually by 2020.

The Nefila HIPS and Nefila PC filaments

Nefilatek’s recycled filaments aim to have “a smaller impact on the planet” for 3D printing. The Nefila HIPS Black, the company’s first filament, is made from high impact polystyrene recycled from the electronic waste of Montreal. Advantages of the filament includes impact and heat resistant 3D prints, while Nefilatek claims it maintains the same characteristics as standard ABS. The HIPS filament can also be dissolved and smoothed with sustainable oils D-limonene and Turpentine.

The company is currently running final tests on the extrusion process of its Nefila PC filament before commercialization. Made from 100% recycled polycarbonate thermoplastic polymers, the filament is geared towards technical applications due to its solid and flexible mechanical properties. It is also resistant to wide temperature variations (-50 ° C to + 130 ° C).

Nefilatek is also working on developing a white variant of its Nefila HIPS filament, and is also ready to operate R & D tests for several other materials including nylon and polypropylene. Since initially beginning development of its filaments in 2018, Nefilatek launched a Kickstarter in January 2019, in order to fund further R & D of its filaments, with the goal if bringing them to market. The company plans to ship its Kickstarter orders of filaments in June, 2019.

Filaments made from recycled materials

Several other initiatives have also been established that help reduce the environmental impact caused by 3D printing, using recycled materials to create 3D printing filaments. Examples include the ONE PET filament from UK 3D printer filament brand Filamentive. The company provides a 100% recycled plastic filament made from post-consumer PET plastic bottle waste. ONE PET was made in collaboration with Tridea, a company specializing in converting plastic waste to 3D filament.

Furthermore, researchers from the U.S. Army Research Laboratory (ARL) have also used recycled (PET) plastic, found in water bottles, yogurt containers, and other recyclable waste materials, to create 3D printing filaments. Using reclaimed materials allows service members to use 3D printing to speedily fabricate replacement parts for military vehicles, weapons, and equipment.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now, and choose the best initiative using 3D printing to establish a better world.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows filaments from Nefilatek. Photo via Nefilatek.