Oryx Additive has announced the launch of a new chemical cleaning agent for removing support material from Fused Deposition Modeling (FDM) 3D printed parts.

Developed in-house by the company’s team of US engineers, src1 is said to work efficiently and rapidly, dissolving support material at twice the speed of other cleaning agents. Oryx Additive says its product has the potential to “set a new standard for FDM post-printing,” particularly among 3D printing bureau, lab and industrial adopters.

“We listened to our customers, understood the needs for industrial additive manufacturing and found that current technology limits the ability to maximize support removal, and with this, src1 was born,” explained Keith Jeffcoat, CEO of Oryx Additive. “We’re happy to release another trusted product with solid results.”

Introducing Support Removal Chemistry

Oryx Additive’s Support Removal Chemistry or ‘src1’ cleaning agent has been developed from the ground up to allow users to dissolve the supports of 3D printed models as quickly and with as little mess as possible. The product has been specifically formulated to tackle Stratasys’ SR-30 material, a polymer designed to support the production of parts with complex overhangs from high-temp filaments.

With a dissolution speed twice that of the next-leading cleaning agent competitor, src1 is said to be ideal for those with time-sensitive needs, such as 3D printing service providers or those engaged in product prototyping. The product is also being marketed as a partner for the Oryx sca1200ht and Oryx sca3600 support removal machines.

Designed to facilitate rapid soluble support dissolution, the units allow users to balance their need for thorough excess removal, with maintaining the dimensions of delicate or intricate components. Whether used with these machines or another of their choosing, src1 allows adopters to post-process parts at a high level of efficiency, with just one packet being needed per twelve gallons of water.

Post-processing FDM parts at pace

src1 was formulated and tested in the US, as part of an extensive R&D process by Oryx Additive. During this development phase, src1 performance testing revealed that it was capable of removing SR-30 from 3D printed five-sided box models at a pace of 3.65 grams per hour, a speed 112.2% faster than that of an unnamed leading competitor.

In later evaluations, the company sought to assess the efficacy of src1 over time, by using it to dissolve the supports of similarly-complex models over a sustained period. While results showed that the market competitor began to lose cleaning effectiveness after 0.75 lbs was dissolved, src1 lasted twice as long, and the bath only needed refreshing after the team got through 2 lbs of cleaning material.

As a result, the engineers behind the research concluded that “one application of src1 lasts twice as long as its leading competitor.” In practice, this means that those who switch to Oryx Additive’s product stand to require half the amount of cleaning agent, potentially enabling them to reduce their post-processing spend.

Optimizing post-processing with Oryx

Removing support materials is a significant part of finishing, but there’s often more work that needs to be done before the final product is ready for distribution. Using its accumulated 3D printing experience, Oryx Additive specializes in helping manufacturers streamline this process, and ensure they maximize the quality and throughput of their final prints.

Last year, its drive for post-processing efficiency saw Oryx Additive partner with Arburg to launch support removal systems for the latter’s customers, which enable Arburg Freeformer 3D printer users to automatically finish industrial end-use parts.

Oryx Additive aims to work with others in the development of solutions that meet similar customer needs. Whether these be in the identification of a cost-effective semi-automated workflow, or a lights-out, fully-automated system, the firm’s team of engineers collaborate with clients to understand their needs, by analyzing their print jobs, desired outcomes and constraints.

By fully understanding customer needs, Oryx Additive comes up with viable, value-based solutions that allow customers to achieve maximum efficiency and productivity. According to the company, trust in its products and the potential of its clientele are crucial to this process, which ultimately “removes the limitations of internal structures,” and “pushes 3D printing’s limits.”

Those interested in doubling their support removal speed can buy Oryx Additive’s src1 at a price of $199.00 for a 12-pack case, or partner with Oryx Additive’s engineers now via the company’s dedicated online store.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

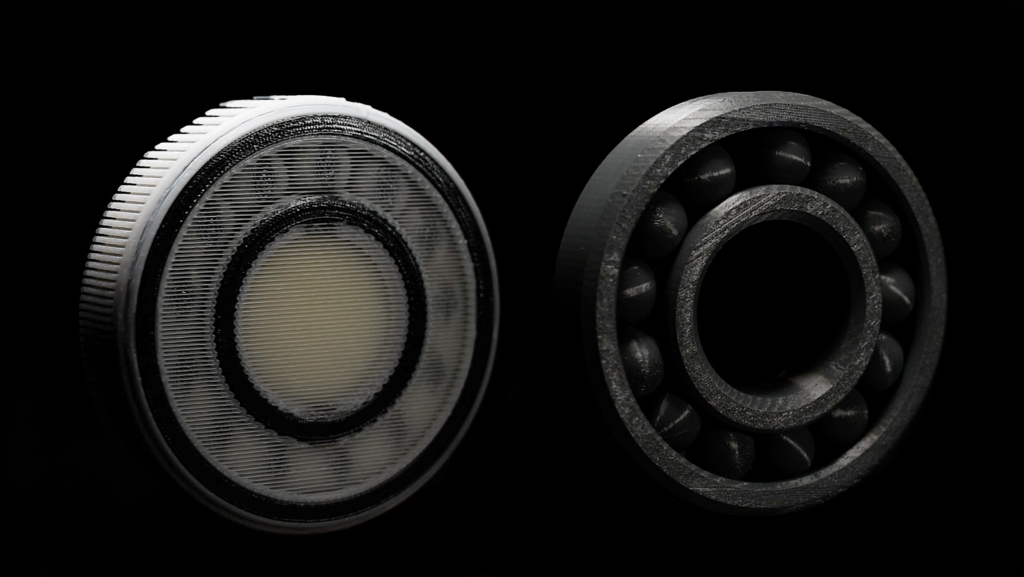

Featured image shows an FDM 3D printed part treated with Oryx Additive’s src1 solution. Image via Oryx Additive.