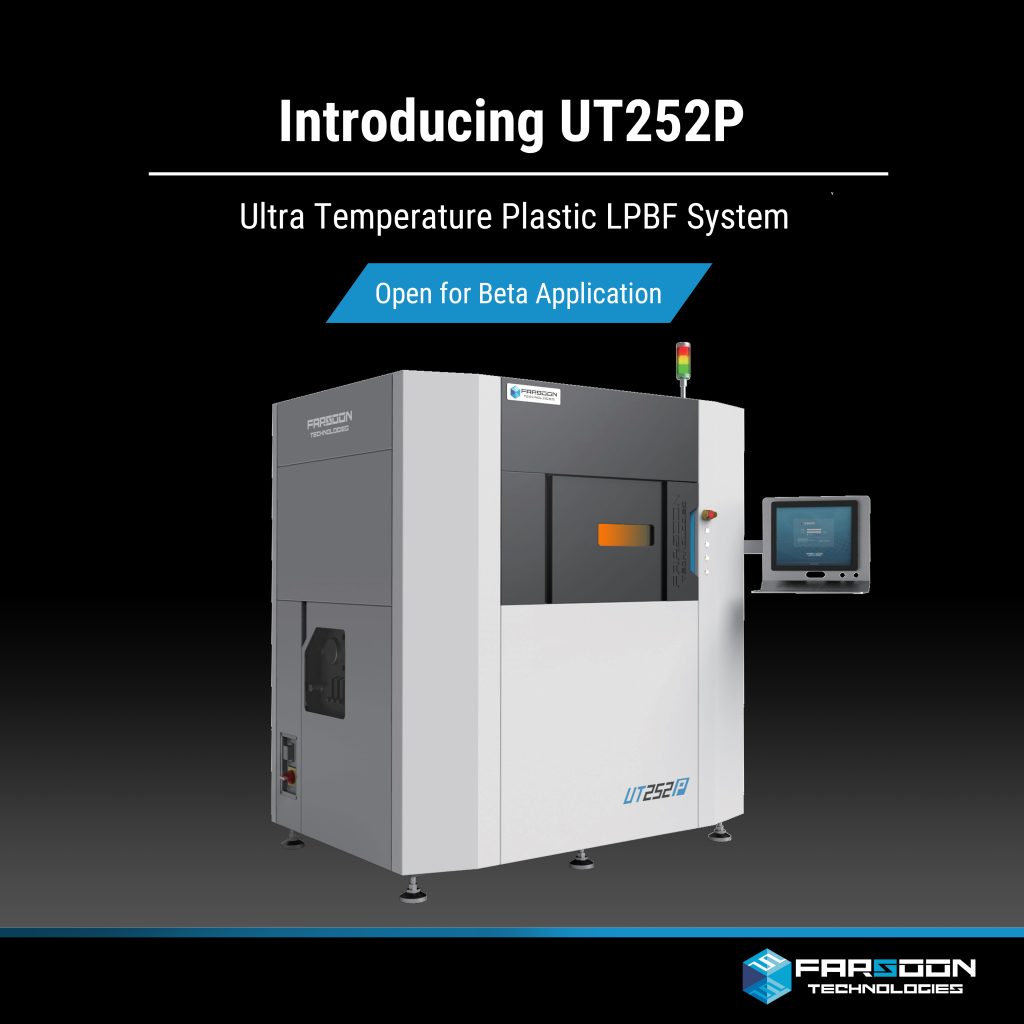

Chinese 3D printer manufacturer Farsoon has introduced the UT252P, an ultra-temperature configuration system designed to cater to high-temperature material applications.

Since its debut in 2014, Farsoon’s 252P platform has gained recognition among technical research institutes, chemical manufacturers, and small-scale production providers. This popularity is primarily attributed to the platform’s open approach and its ability to operate at temperatures of up to 280°C, says the manufacturer. These attributes have enabled it to support numerous chemical manufacturers in their quest to develop specialized engineering materials and validate small-scale production runs.

UT252P: A new era of high-temperature 3D printing

The newly announced UT252P represents a notable evolution of the 252P platform. It features an enhanced chamber temperature capacity capable of processing materials with melting points exceeding 340°C. This system boasts a versatile build envelope measuring 250×250×320mm and is equipped with a robust 100W CO2 laser, which makes it suitable for applications in fields such as material engineering, medical, and aerospace that require high-temperature capabilities.

One of the key advancements in the UT252P is its improved 8-zone temperature shielding and thermal control. These enhancements enable the system to handle high-temperature, and high-performance engineering materials, including PA6, PA66, PPS, PAEK, PI, and PTFE, making it useful for end-use applications in industries that demand materials with superior durability and resistance to extreme conditions.

According to Farsoon, the development of the UT252P has involved collaboration with multiple material suppliers to optimize high-temperature powder materials for Laser Powder Bed Fusion (LPBF) processes. A notable achievement is the successful sintering of a PAEK family material with a melting point exceeding 340°C. This material exhibits notable characteristics, including exceptional chemical and thermal resistance, low moisture absorption, fire resistance, and enhanced wear resistance.

During the Beta testing phase, components produced using the UT252P consistently demonstrated reliable results in terms of thermal stability, surface quality, and mechanical properties, showcasing the system’s potential for high-temperature 3D printing. Furthermore, the UT252P ultra-temperature system is available for Beta program applications in the Chinese market.

Technical specifications of 252P series

| Technical Data | (Super-temperature) ST252P |

| External Dimensions (L×W×H) | 1735×1225×1975 mm (68.3×48.2×77.8 in) |

| Build Cylinder Size1(L×W×H) | 250×250×320 mm (9.8×9.8×12.6 in) |

| Net Weight | Approx. 1700KG (3747.9 lb) |

| Laser Type | CO2 laser, 1×100W |

| Scanner | High-precision galvo system |

| Scanning Speed | Max.10 m/s (32.8 ft/s) |

| Max. Chamber Temperature | 280°C (536℉) |

| Technical Data | (High-temperature) HT252P |

| External Dimensions (L×W×H) | 1735×1205×1975 mm (68.3×47.4×77.8 in) |

| Build Cylinder Size1(L×W×H) | 250×250×320 mm (9.8×9.8×12.6 in) |

| Net Weight | Approx. 1700KG (3747.9 lb) |

| Laser Type | CO2 laser, 1×55W |

| Scanner | High-precision galvo system |

| Scanning Speed | Max.10 m/s (32.8 ft/s) |

| Max. Chamber Temperature | 220°C (428℉) |

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows UT252P, an ultra-temperature configuration system. Image via Farsoon.