FabRx, a specialist in pharmaceutical 3D printing, has launched its M3DIMAKER 3D printer for the manufacture of personalized drug delivery devices. The University College London (UCL) spin-out first introduced the M3DIMAKER system at ILMAC Exhibition in Switzerland which took place on the 24th – 27th of September 2019. The release comes after FabRx completed trials with the machine in hospitals, pharmacies and research institutions around the globe.

3D printing personalized medicine

Modern drug delivery devices, particularly oral tablets, are typically mass manufactured using conventional methods, creating dosage forms with identical dosage and release profiles. The distribution of identical tablets in a ‘one-size-fits-all’ manner can lead to side effects from excessive dosage or a lack of treatment from under-dosing patients. This is especially true when treating minors, where tablets are often halved or quartered to roughly meet dosage requirements.

FabRx believes 3D printing will shine when it comes to optimally meeting the need for age and physique-dependent medical formulations. Patient-specific dosage profiles coupled with the ability to produce polypills – multiple medications combined into single printlets – will allow for the treatment of patients with a greater degree of precision and accuracy.

The FabRx M3DIMAKER

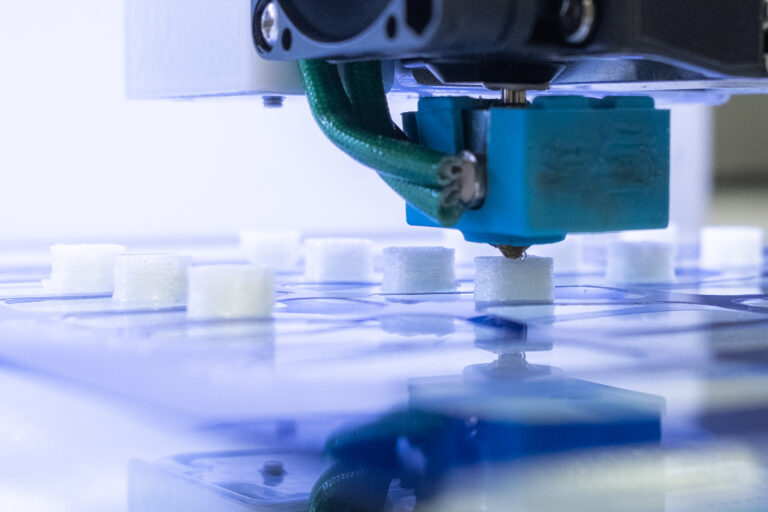

The M3DIMAKER is a desktop-sized FFF system specially designed to extrude medical formulae in the required doses selected by clinicians. The pharmacists operating the machine have access to sophisticated fingerprint readers incorporated into the system, allowing only qualified personnel to fabricate tablets. The addition of in-situ camera monitoring also allows for constant quality control and print failure detection.

Operators of the M3DIMAKER have the option to choose between three printing nozzles which adapt the system to different manufacturing needs, which include small batch production for clinical trials and precise personalized dosage forms for individuals. According to FabRx, the preparation of 28 printlets, or one month’s medication, takes around 8 minutes to complete depending on the drug.

Dr. Alvaro Goyanes, Director of Development at FabRx stated: “We are delighted to be launching our state-of-the-art 3D printing system in light of the recommendations from the regulatory organisations into the pharmaceutical market. I truly believe that we are one step closer to personalised medicine thanks to the M3DIMAKER.”

The 3D printing of drug delivery devices has seen significant research in recent years. Released earlier in 2020, a special issue editorial by scientists from Queen’s University Belfast details the production of pharmaceuticals and drug delivery devices using a variety of 3D printing technologies. Elsewhere, focusing on unconventional drug delivery devices, Washington State University researchers have 3D printed a contact lens to rival laser eye surgery. The lens is home to a microneedle array capable of delivering medication directly to a patient’s eye.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows M3DIMAKER 3D printing tablets directly onto blister packaging. Photo via FabRx.