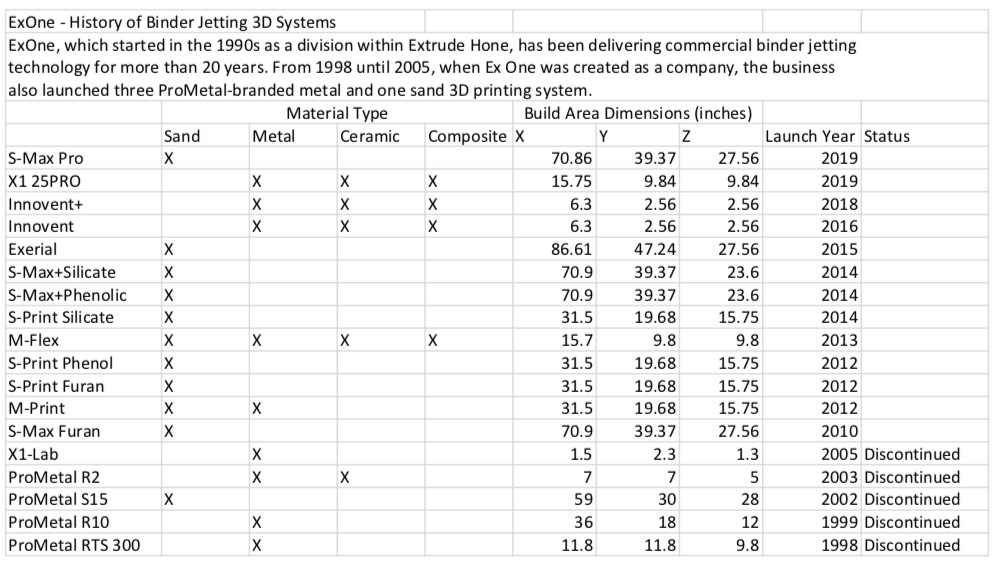

Leading industrial 3D printer manufacturer ExOne made several new product and strategic announcements at the 2019 GIFA International Foundry Trade Fair in Dusseldorf, Germany.

The global launch of the new S-Max Pro, an industrial sand 3D printer, took center stage. Additionally, ExOne announced a strategic partnership with Siemens to enable connected 3D printer factories, and the launch of a new marketing initiative: “Collaborate. Innovate. Accelerate.”

“This is an exciting time for ExOne,” said ExOne CEO John Hartner. “With the recent release of our X1 25PRO 3D metal printer, and now the launch of our new S-MAX Pro industrial 3D sand printer, ExOne is delivering cutting-edge 3D binder jetting technology solutions to a broad range of industries and applications around the world.”

Collaborate, Innovate, Accelerate

In its 14th edition, GIFA hosted an estimated 40,000 visitors from over 2200 exhibitors from the metallurgy, heat technology, and foundry industries from June 24-29th.

Charlie Grace, ExOne Chief Customer Officer, said interest in ExOne’s products is strong across the company’s portfolio of both sand and metal 3D printers. “It’s exciting to bring the latest in binder jetting solutions to companies that can really help save time and money, as well as develop innovative new solutions.”

One new, driving factor at ExOne is a commitment to its new internal and external marketing initiative: Collaborate. Innovate. Accelerate. More than just a tagline, Hartner explained, this message has been adopted “to emphasize ExOne’s commitment to leadership in industrial 3D printing and focus on building and strengthening customer relationships.”

To better reflect this mission, the company’s website has undergone improvements to better highlight ExOne’s growing portfolio of sand and metal 3D printers. Moreover, the new interface makes it easier to navigate through menus, as well as its growing list of qualified industrial materials, which includes six metal 3D printing materials.

Further, fulfilling the Collaborate portion of this initiative, ExOne recently inked a new partnership with Siemens that will bring the company’s Digital Enterprise Portfolio of software and automation technology to ExOne customers. More specifically MindSphere, the open cloud-based IoT operating system from Siemens, will support S-Max Pro operators providing advanced analytics and real-time data. This integration aims to optimize decision-making and identify anomalies for improving maintenance and repair activities.

The S-Max Pro 3D printer

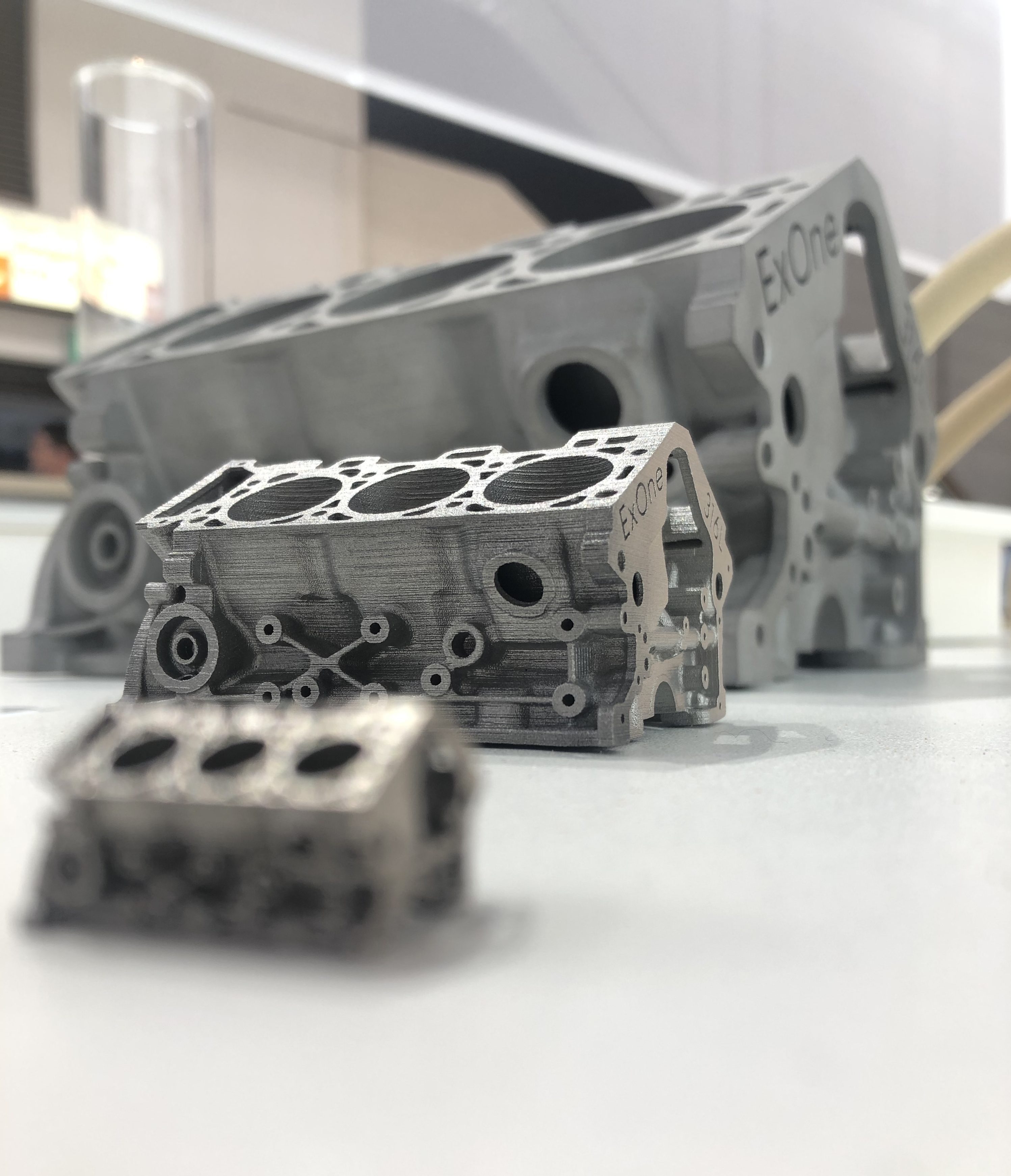

The S-Max Pro is ExOne’s 10th industrial sand 3D printing system to date, with external dimensions of 10.40 x 3.52 x 2.86m and a build volume of 1260L. It is designed for the production of complex parts with various casting materials.These features are enabled by a newly developed printhead and a fully automated recoater. Molding material in the system can also be replaced in a timely and straightforward manner facilitating quick machine turnaround.

Achieving print speeds of up to 135 l/h (18 s/layer), this system is also capable of producing two 1800 x 1000 x 700mm job boxes, each with a volume of 1260 L, in 24 hours. On display throughout GIFA 2019 the S-Max Pro generated considerable interest from visitors, and is expected to feature in the company’s presentation at other events throughout the year.

Earlier this year, ExOne also announced the new X1 25PRO industrial metal 3D printer, the sixth metal 3D printer since ExOne’s founding.

Visit ExOne to find out more about the new S-Max 3D printer here.

Stay abreast of the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter, and following us on Twitter and Facebook.

Looking for opportunities in the additive manufacturing industry?Visit 3D Printing Jobs now.

Featured image shows the ExOne team at the 2019 GIFA International Foundry Trade Fair. Photo via ExOne.