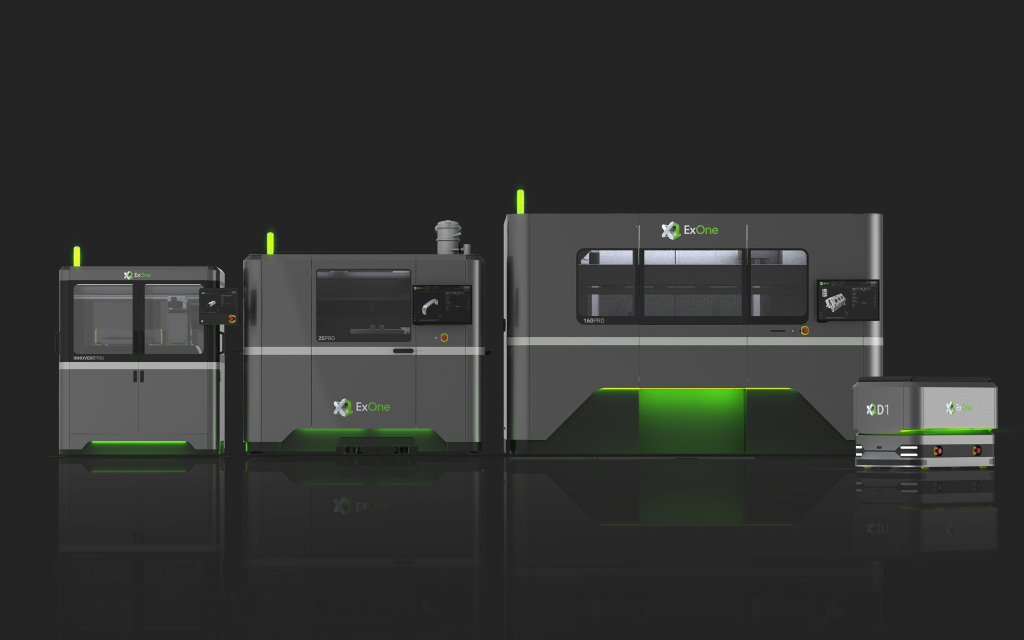

ExOne, a manufacturer of binder jet 3D printers, has announced a whole slew of developments regarding its 3D printing business.

Firstly, ExOne has announced the first set of orders for the firm’s new InnoventPro 3L metal 3D printer. Among the inaugural orders, Neoshapes, a Geneva-based jewelry startup, will use the InnoventPro 3L to 3D print luxury goods using precious metals such as gold, platinum, and silver. Global tech firm Siemens was also one of the first customers to purchase the printer.

The company has also announced the launch of its new X1 Powder Grip, a two-liter powder container designed to enable ultra-fine MIM powder management on the InnoventPro system.

Finally, the firm’s stockholders have voted to approve ExOne’s acquisition by Desktop Metal, a rival OEM of binder jet 3D printing systems. The deal is expected to close by the end of the week, subject to customary closing conditions, and the final voting results will be filed with the U.S. Securities and Exchange Commission (SEC). Once complete, ExOne’s common stock will be removed from public markets and it will become a wholly-owned subsidiary of Desktop Metal.

Neoshapes, Siemens, and the InnoventPro 3L

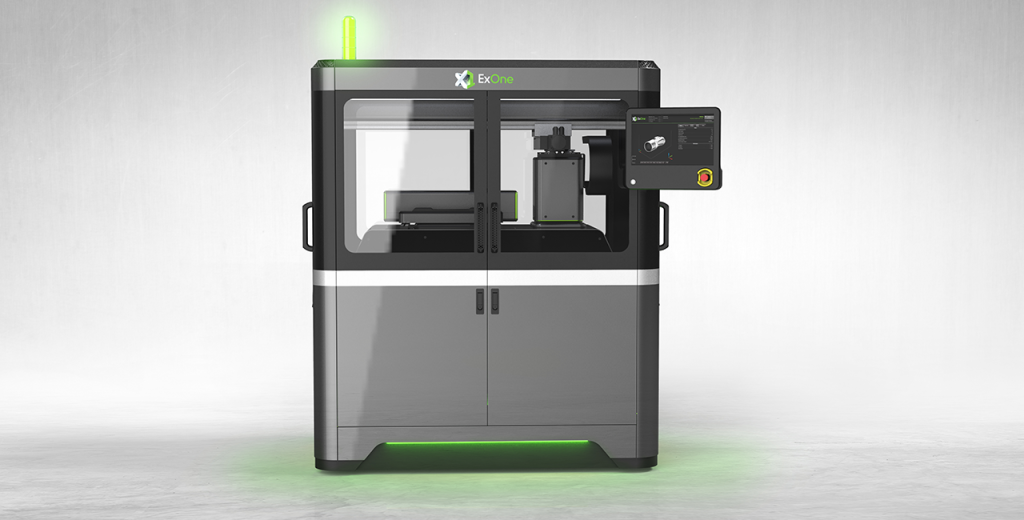

The InnoventPro 3L is ExOne’s latest entry-level metal binder jet 3D printer. Intended as an upgrade to the Innovent+ 3D printer, the InnoventPro offers three times the build area (125 x 220 x 100 mm) of its predecessor with the same printhead as the firm’s X1 25Pro system. Equipped with ExOne’s Triple ACT advanced compaction technology and print speeds of up to 700 cc/hour, the InnoventPro is suitable for academics, researchers, and a variety of manufacturers seeking R&D, prototyping, and end-use production.

Neoshapes has already worked closely with ExOne on a proof-of-concept project for printing with precious metal on the Innovent+ 3D printer. Starting next year, the startup will scale the technology for the upcoming InnoventPro 3L in a bid to enable a new level of productivity and quality in the 3D printed luxury goods market.

Stéphane Vigié, board member of Neoshapes, said, “Our team at Neoshapes plans to run an ambitious R&D project covering all aspects of manufacturing in order to finally allow luxury brands to benefit from repetitive batch scale manufacturing of revolutionary designs, with unrivaled quick time to market.”

On the other hand, Siemens will house its newly-purchased InnoventPro at its Charlotte Advanced Technology Collaboration Hub (CATCH) located in Charlotte, North Carolina. The binder jet system will be used to develop new materials and processes that Siemens will scale up for the production-ready X1 160Pro. The InnoventPro already features a Siemens control system, which consolidates the printer’s drives, motors, sensors, and the Siemens MindSphere IoT operating system.

Tim Bell, Head of Additive Manufacturing at Siemens, adds, “We’re very excited to feature the InnoventPro in our Technology Collaboration Hub, and we look forward to demonstrating how to integrate advanced additive manufacturing systems such as the InnoventPro into our end-to-end Digital Thread.”

The X1 Powder Grip

Developed as part of the InnoventPro’s comprehensive new powder management system, the X1 Powder Grip is designed to help users eliminate scooping, dumping, powder clouds, and cleanup in the metal binder jetting workflow. The container weighs around 9kg when fully loaded with 316L stainless steel.

To load new powder into the InnoventPro, users will only need to slot two X1 Powder Grip containers into a powder hopper which can be found at the back of the 3D printer. Once the powder release valve is unlocked, a separate conveyance system takes the hopper from the loading position to the build area where it can be accessed for printing and recoating. ExOne has also designed the X1 Powder Grip to enable easy powder reclamation and reuse when used in conjunction with the firm’s new depowdering station.

Following the acquisition of Freshmade 3D’s patented 3D printed tooling technology earlier this year, ExOne also recently launched its own portfolio of 3D printed tooling products. Aimed at manufacturers, the new X1 Tooling range is reportedly the world’s largest offering of industrial-grade 3D printed tooling. The product line includes tooling for plastic injection molding, forming, composite layups, metal castings, and more.

More recently, the company partnered with powder metallurgy specialist SSI Sintered Specialities to ramp up its production capabilities. As part of the firms’ collaboration, SSI Sintered Specialties will install ExOne’s X1 160Pro and InnoventPro 3L systems at its HQ in Wisconsin next year, where they’re set to be used within extensive binder jet material, automation, and process R&D, while also manufacturing complex parts for the company’s clientele at scale.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the X1 Powder Grip container. Photo via ExOne.