Four months after launch on the Ariane 5 spacecraft June 1 2017, the Airbus-made EUTELSAT 172B satellite has reached geostationary orbit 35,786 kilometres above the Earth’s equator. Reaching the determined position was achieved by electrical as opposed to chemical propulsion, making it the fastest electric orbit raising (EOR) to date.

Construction of the craft has been aided in part by additive manufacturing, creating a unit weighing only 3,550 kg – undercutting the typical weight of satellites of this specification by between 1,000 kg and 2,500 kg.

EUTELSAT 172B is now in GEO just 4 months after launch, setting a new record for #satellite electric orbit raising! https://t.co/25kqdiAzpd pic.twitter.com/HN44ECLGij

— Eutelsat (@Eutelsat_SA) 11 October 2017

Better broadband and in-flight entertainment

The EUTELSAT 172B is expected to remain in service for over 15 years, delivering broader, more powerful, service to Eutelsat customers in South East Asia, and double the broadcast capacity to the Asia-Pacific region. Additionally, the satellite will be used to transmit in-flight broadband connection for Panasonic Avionics Corporation that provides entertainment for commercial airlines.

Pushing the envelope of innovation

Yohann Leroy, Eutelsat’s Chief Technical Officer, details some of the technologies used to make the EUTELSAT 172B a success, “In combining electric propulsion, High Throughput capacity, robotic arms and 3D printing techniques, our new satellite also reflects Europe’s capability to push the envelope of innovation in order to increase the competitiveness of our business.”

The model is made using the Eurostar E3000 satellite template, introduced by Airbus Defence and Space in 2004. In March 2015, Airbus added a 3D printed antenna bracket to the model that was, at the time, the first space-certified part of its kind.

In the EUTELSAT 172B a bracket is in fact named as one of several elements on the craft to be made using 3D printing. The material infill and design makes the parts 35% lighter than its conventionally manufactured equivalent, giving the added bonus of expedient delivery and consolidation.

A revolution in satellite production

3D printing is helping to significantly reduce the cost of satellite production across the industry. Surrey Satellite Technology is a firm believer in the process and defence giant Lockheed Martin is investing heavily in next generation satellite development.

For the first time this year, the aviation section of Airbus installed a metal 3D printed part on an in-service aircraft. The multinational aerospace company has also successfully tested a 3D printed controlling block for inside airplane wings, and is working with Sciaky on the potential use of EBAM techniques.

The 3D Printing Industry newsletter delivers aerospace, medical, automotive and more news on a regular basis. Subscribe here, and get updates from us on Twitter and Facebook. Check out our page for 3D printing events here.

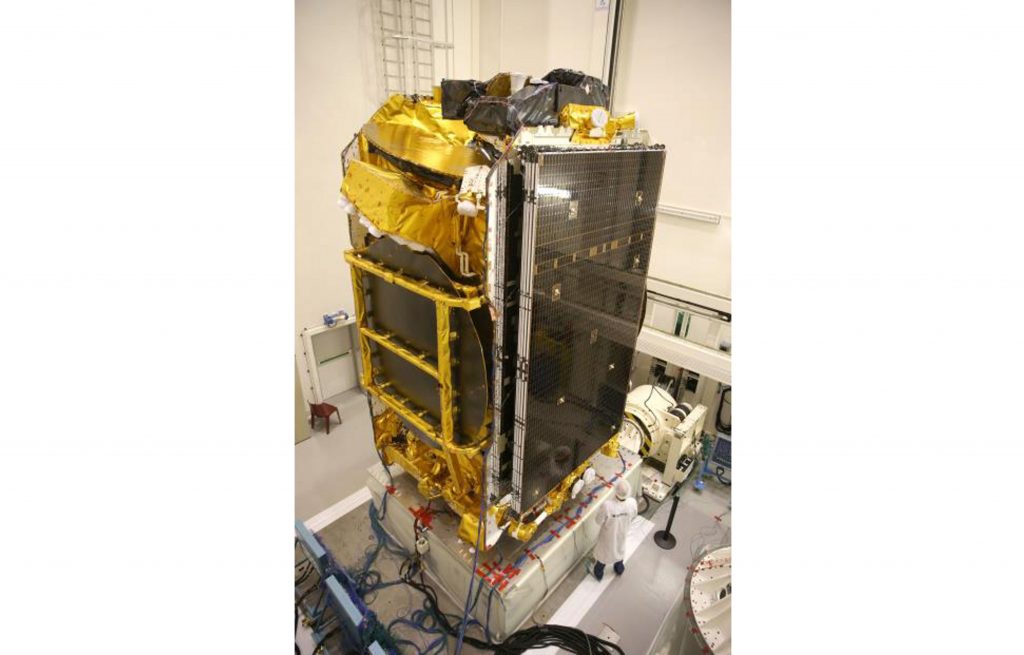

Featured image shows a graphic representation of the EUTELSAT 172B satellite. Image via Airbus Defence and Space