The abundance of 3D scanning booths and 3D scanners in general at Euromold demonstrated that 3D scanning is big and that photogrammetry – even with all of its limitations in terms of portability – is here to stay. Handheld 3D scanners, desktop 3D scanners, and 3D scanning booths were among the biggest and most interesting new products at this edition of the fair. I rapidly explored most of them, and I even got 3D scanned in some cases.

The first 3D scanning booth I visited was the Dooblicator. I had spoken with Miki Devic’s, Doob Group’s marketing director, and promised I would stop by. With stores in Dusseldorf, Tokyo, New York City, Los Angeles, and more, Doob is arguably the most well-established 3D scanning and physical photography company in the world, at this point. Doob’s was also the last booth I visited, as I stopped by right before leaving to get my 3D scan and 3D print performed. The system is based on a number of SLR camera’s; however, it is Doob’s proprietary software that allows for a fast and high quality post production of the 3D scan.

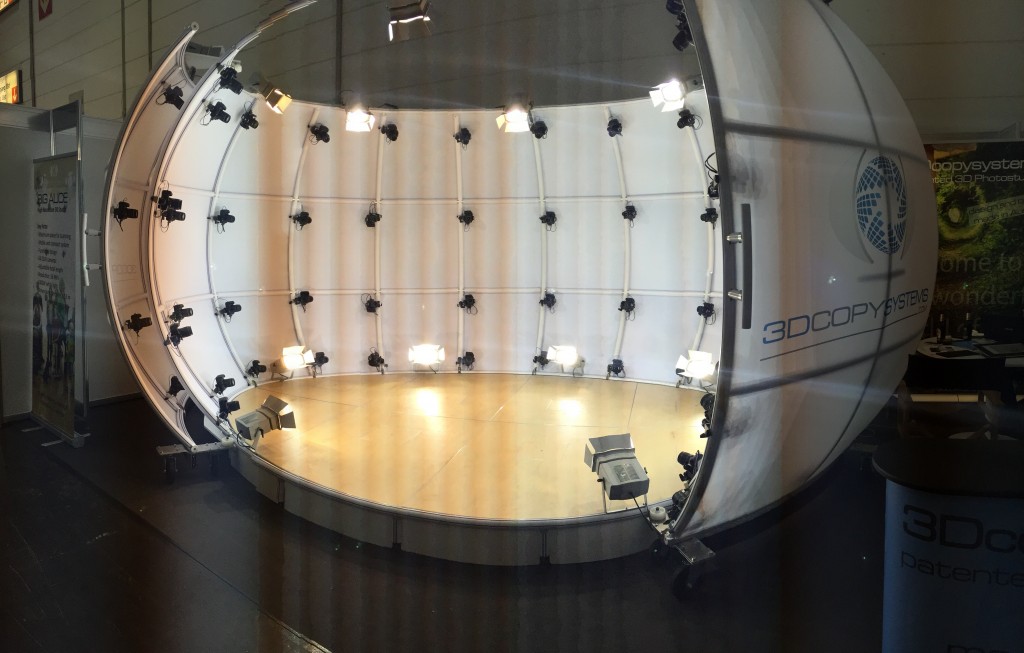

The most noticeable 3D scanners I ran into were the BIG ALICE and little ALICE photogrammetry booths by a new Austrian company called 3DCOPYSYSTEMS. Bernhard Mayrhofer explained that they see their systems as a sort of Alice in Wonderland rabbit hole. The largest model can fit as many as six people at a time and costs about €80,000. The smaller model uses raspberry pi cameras and costs significantly less.

I, then, passed by 3Dscamera, the company behind the Bella Figura 3D Studio franchising project. The 3Dscamera system consists of several elegant black columns with integrated cameras for image capturing. The system is targeted specifically at professional photo studios that want to introduce the 3D photo option to their customers.

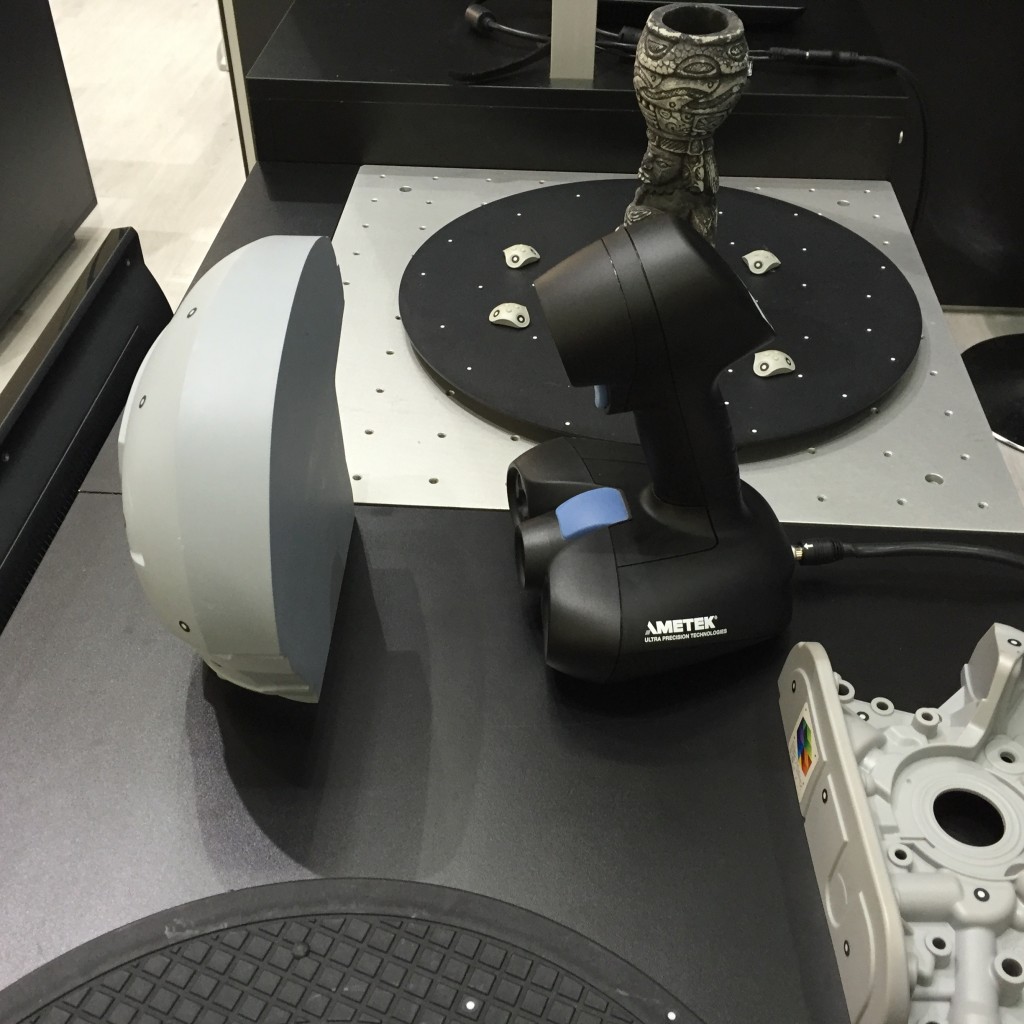

At this point, I got to the large Creaform stand, where I realized that I have never actually tried 3D scanning anything with a serious handheld 3D scanner. Because affluence was slow on the first two days, I was actually able to try out the Go!Scan3D model (the low-end model, priced at around €25,000). I was impressed by how easy it was to use and how accurate the system was in capturing detailed shapes and textures, guiding me in covering all elements.

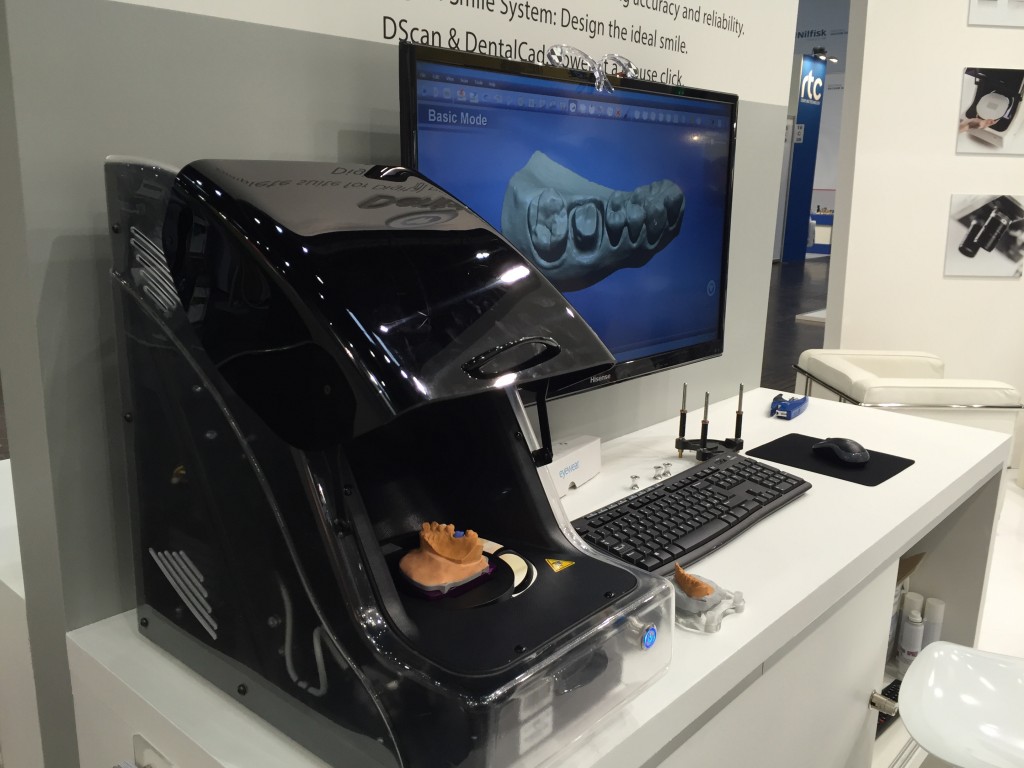

Taking advantage of the fact that companies actually had more time to dedicate, compared to previous Euromolds, I then went on to EGS Solutions, an Italian manufacturer of dental 3D scanners. Here, Serena Santoro showed me exactly what they are used for, which still remained somewhat of a mystery to me. In fact, the use of 3D scanners in the dental sector is evolving rapidly. They are used mainly to capture the physical model that dental technicians create by traditional molding procedures. Once the mold is digitized, it can be used to model and 3D print temporary caps or even more permanent caps in metal and other materials. In the future, the use of intra-oral 3D scanners and MRI’s can allow dental technicians to skip the traditional molding altogether. The new EGS 3D scanner allows for a 3D scan of both the upper and lower jaw at the same time for faster processing.

Getting back to handheld 3D scanners, I, and – from what I heard – not only I, was impressed by the THOR 3D scanner, a new system that wants to compete with Artec’s EVA in the world of B2C body scanning. Some of the founding members at THOR come from Artec and have founded the company to push the research and development of new scanning systems, focusing on removing the need for cables and by introducing an on-board touch screen with three simple on-screen controls (start, stop, delete). Artec, of course, is not entirely happy about this (to use a huge euphemism): the Russian leader in handheld 3D scanning had its own space just a few booths away, where it showed off its EVA and Spider technology.

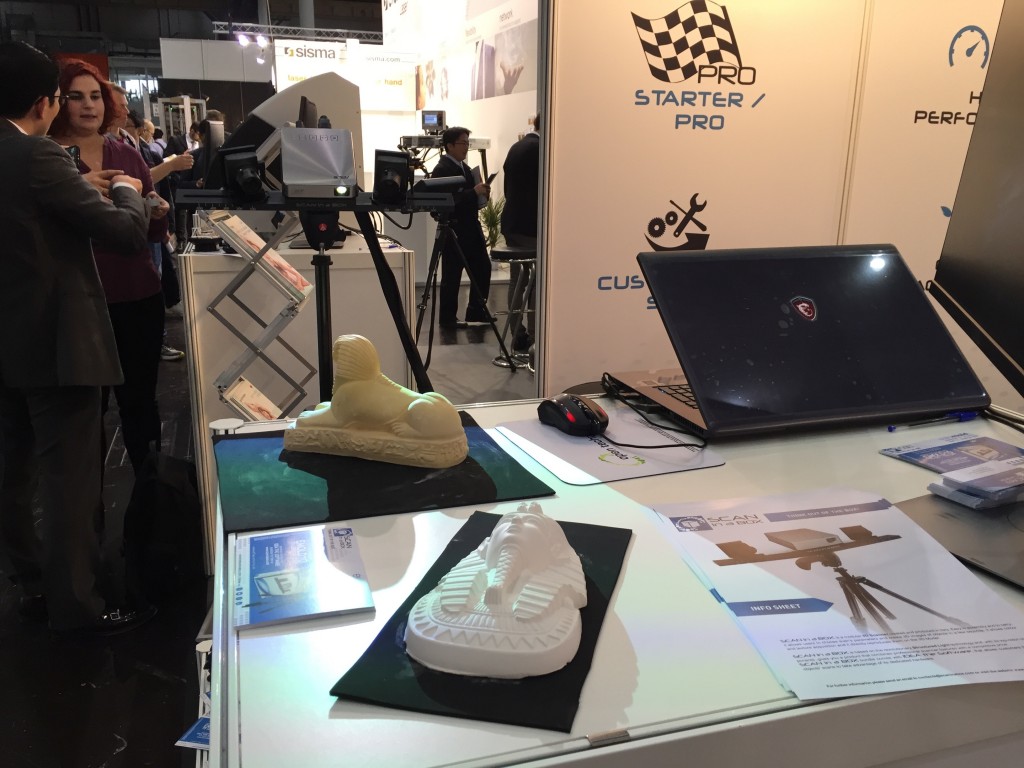

Other companies, such as Open Technologies, another Italian manufacturer of dental and jewelry scanners, have introduced more affordable solutions. In particular, Open Technologies launched the “Scan in a Box” brand for an affordable rotation projection/laser 3D scanning system. On the opposite side of the spectrum is Faro, the absolute leader in moving arm 3D scanners. The company was showing off its $100,000 moving arm + blue light 3D scanning system, that was announced just a few months ago.

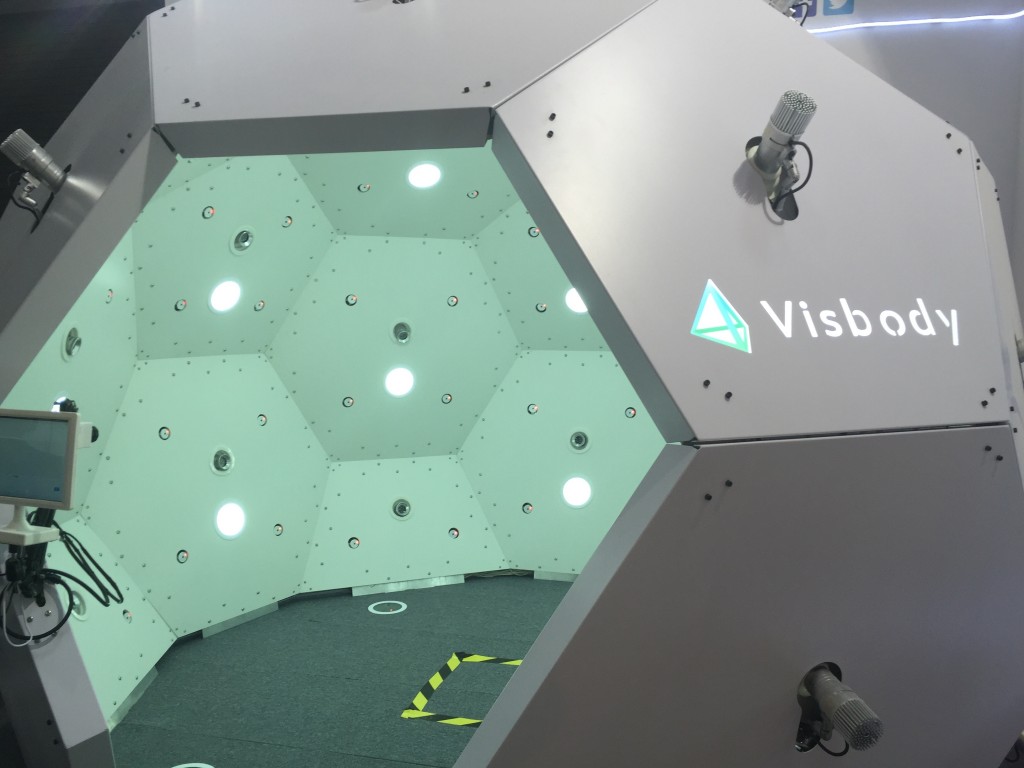

More booths I visited included the large Visbody system, built by a Chinese company called Suanier Tech, based in Xi’an. The Visbody Photogrammetry Booth is arriving on the market at a much lower price than most comparable systems and offers the advantage of introducing a series of modules that can (relatively) easily be assembled and disassembled. Finally, just as I was on my way out to catch my plane, I came upon ikizin, a Turkish photogrammetric 3D scanner supplier that also distributes 3D Systems 3D printers (including the full color Projet 660 and 4500, typically used for B2C products relating to physical photography). Birkan Sahi showed me that they have developed a revolutionary technique to empty out the 3D printed models, thus further reducing the use of materials and costs.

3D scanners are coming in all shapes and sizes, from all over the world, however, much like with 3D printing, it is not so much that the technology needs to further evolve, as much as we need to figure out how to exploit it to the fullest. I’m betting we are going to see some interesting new applications in the next 12 months.

*This article was updated on September 29th to reflect the fact that the BIG ALICE booth by 3DCOPYSYSTEMS costs €80,000 and not €150,000 as previously indicated.