Custom-made wearables provide the exciting opportunity to bring 3D printing to a commercial market. With Under Armour, adidas and China’s Peak Sport all on board, the center of 3D consumer innovation is currently in the footwear market.

Now filament manufacturer eSun is launching a venture to introduce the technology in high street kiosks across China.

RESA Wearables exit stealth mode

eSUN has signed a joint venture with Arizona based startup RESA Wearables.

After years in stealth-mode researching the best way of bringing custom insoles to the market, RESA Wearables was founded in 2016.

Including the HQ in Arizona, the company has offices in New York, and now Shenzhen, China, where it will be launching Shenzhen Resun Healthcare Technology Co., Ltd. with eSUN.

“The Chinese market has a rich history of being interested in body alignment and wearable technology products,” says RESA Wearables, Inc. Founder and CEO Glen Hinshaw.

“This joint venture will enable us to help advance the way that Chinese people understand and address their foot care needs and how they access the products they require for optimal foot health and physical comfort and performance.”

Custom insoles while-you-wait

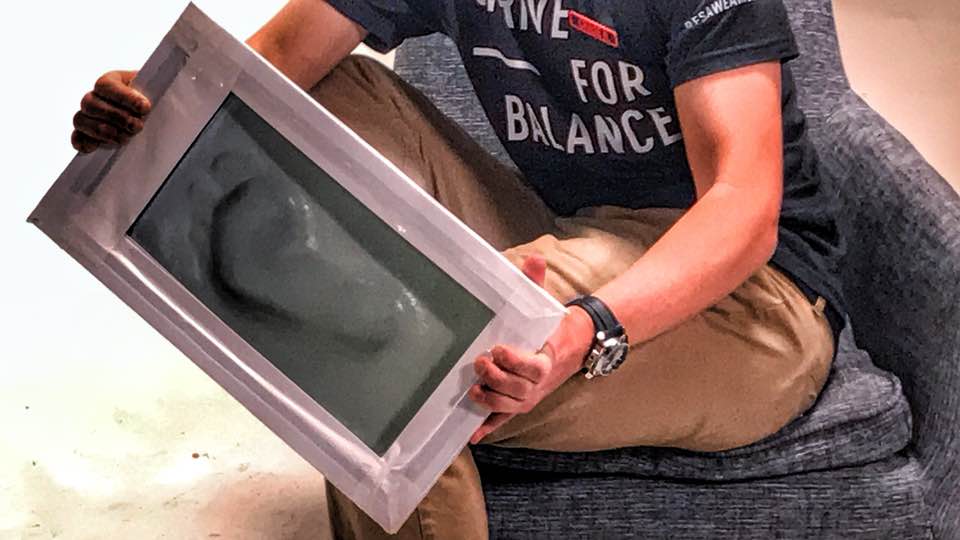

Shenzhen Resun Healthcare Technology Co. kiosks will provide complete end-to-end production of insoles for customer’s shoes. The booths include an advanced foot 3D scanning module that measures the exact proportions of a customer’s foot.

This data is delivered to RESA-made “artificial intelligence CAD insole design software”, where specifications are added according to the hardness, purpose and support needed in a shoe.

The insoles are then 3D printed on-site providing customers with a custom-made product within the hour.

Material development

In addition to the commercial kiosks, eSUN and RESA are committed to developing new proprietary materials and techniques to provide the best possible experience for their customers.

eSUN’s current range of 3D printer filaments includes PLA, ABS, high-performance HIPS, PETG and specials, like eCopper. As with eSUN’s PLA based resin, the materials may even have an environmental conscience.

Read all about the latest 3D printing business deals and introduction to the consumer market on our Twitter and Facebook.

Get insider insight on the industry now by signing up to our free newsletter, or checking out some of the latest 3D printing events near you.

Featured image: A range of shoes with RESA Wearables 3D printed insoles. Photo via resawear on Facebook.