3D printer manufacturer Essentium has collaborated with Malta-based start-up Thought3D to launch a tailor-made all-in-one line of 3D printing adhesives.

Magigoo, a product line of Thought3D, has specifically optimized the new range of manufacturing chemicals to work with Essentium’s High-Speed Extrusion (HSE) platform. The adhesives, which hold 3D prints in place during printing, will also enable Essentium customers to explore a range of new engineering-grade polymers.

“Continuous innovation across the entire 3D printing ecosystem is central to the revolutionary shift to large-scale additive manufacturing,” said Brandon Sweeney, Head of R&D for Materials and Essentium Co-founder. “For customers, these new adhesives enable high-quality prints every time while also being solvent-free and environmentally friendly.”

“Essentium is committed to providing a powerful platform to help manufacturers drive significant performance improvements.”

Essentium’s adhesive innovation

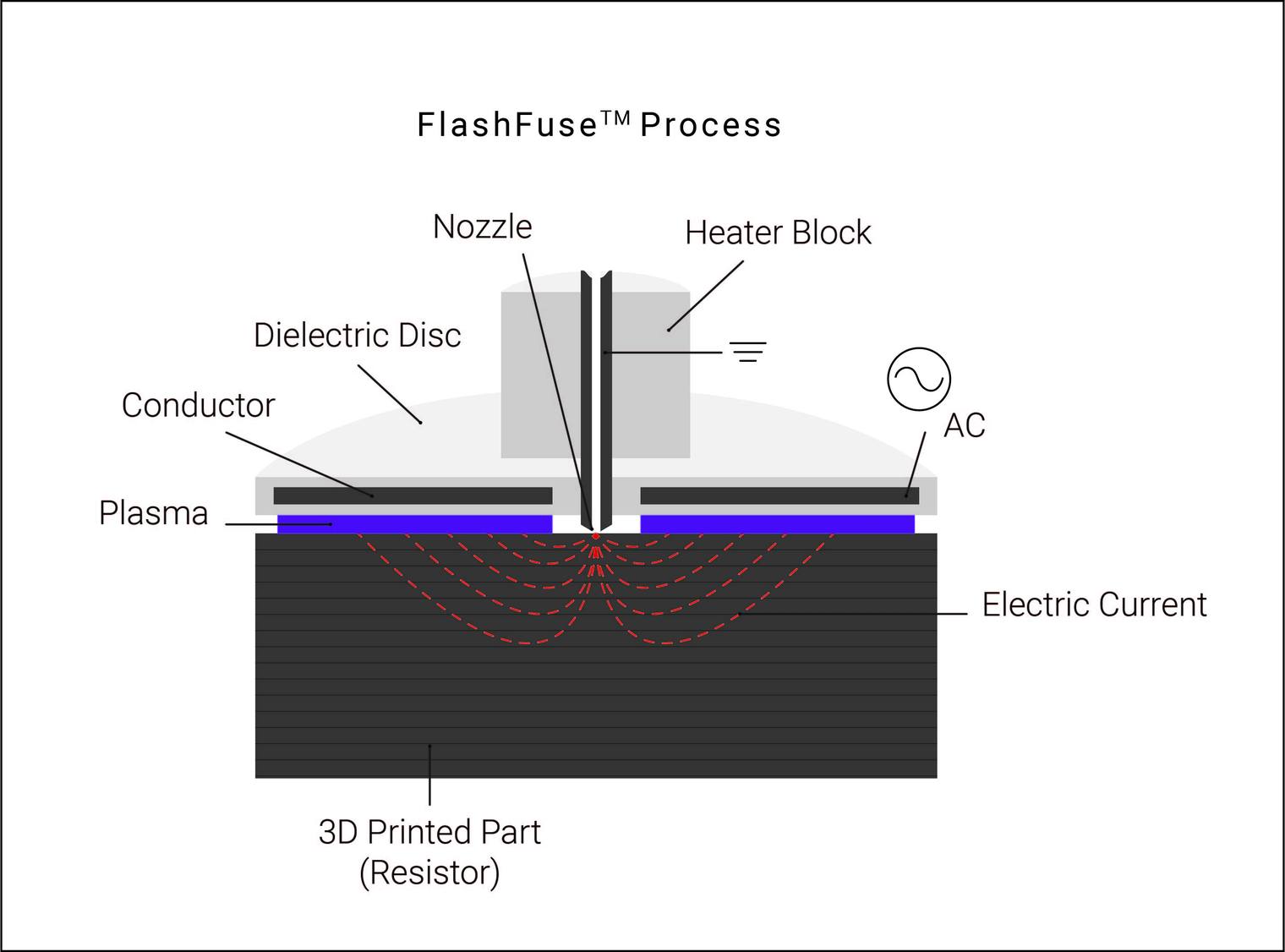

Founded in 2013 and based in Austin, Essentium developed HSE and FlashFuse 3D printing technologies. FlashFuse is a method where the electric charge of plasma is harnessed to improve the 3D printed part strength across the Z-axis. HSE meanwhile, run extruders at 400 to 800 rpm and rotate the heater bands between on and off to keep the plastic molten.

A cylindrical rotating screw is placed inside the barrel which forces out the liquidized plastic substance through a die. As a result, Essentium’s 180-S3D printer can reportedly fabricate faster than 500mm a second; which is significantly faster than traditional Fused Deposition Modeling (FDM) systems.

HSE also contains Essentium’s proprietary heating unit and nozzle, also known as, “The Hozzle.” The system’s non-slip, high torque extruder system allows it to achieve high levels of accuracy, and its HSE nozzle can adjust to temperatures from 20-600°C. Later, in 2019 the firm released its 180•S System which combines FlashFuse and HSE technology within the same platform and is reportedly ten times faster than its industrial competitors.

In light of the COVID-19 pandemic, Essentium started working with the Texas Division of Emergency Management, Military Department and other state-level groups to provide PPE. Based on FDA emergency use authorization, the company began manufacturing protective face mask kits. The reusable masks’ frames were produced with Essentium PA (thermoplastic nylon) optimizing their design and making them easy to clean.

Essentium and Magigoo’s new adhesive range

Magigoo’s latest 3D printing adhesives are compatible with a significant number of Essentium materials, in addition to other brands of standard and high-temperature filaments. Working together, Essentium and Magigoo have optimized four versions of the chemical for the bed-adhesion of different engineering-grade polymers.

The four iterations include standard, nylon, flexible and high-temperature variants, which feature different qualities depending on their end-use applications. Essentium’s high-temperature version is designed to work under thermal pressure, while the standard mixture has been produced with compatibility in mind. Whereas the nylon version is optimized for polyamide materials and the flexible mixture has been produced for printing with Thermoplastic Polyurethane (TPU).

Replicating the structure of a glue stick, each of the adhesives can be applied to the print-bed like glue. The chemical then secures the print in place and ensures it doesn’t move during production. Once, the print job has been completed, the product is ready for post-processing.

Essentium’s and Magigoo’s previous projects

Recently, in March 2020, Essentium announced a partnership with chemical and mineral material specialist the LEHVOSS group to develop high-performance materials for additive manufacturing. The line of PEEK and High-Temperature Nylon (HTN) polymers were created specifically for production-level extrusion-based 3D printing processes.

A year later, in 2019 Essentium secured $22.2 million worth of funding to develop its HSE 3D printing technology. The investment was made by BASF Venture Capital, and 3D software company Materialise.

In 2018, Magigoo introduced four new formulations of its 3D print bed adhesives that were designed to serve large-format 3D printers in partnership with BigRep. The launch included Magigoo PP-GF, an adhesive which was optimized for use with glass fiber reinforced polypropylene. (PP)

What companies do you think are leading the 3D printing industry? Let us know by nominating them for the 2020 3D printing Industry Awards.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway! Enter your design for your chance to win a CraftBot Flow 3D printer.

Check us out on Twitter and Facebook for more updates! Don’t forget to subscribe to the 3D Printing Industry newsletter and keep up-to-date with the latest 3D printing news.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the additive manufacturing industry.

Featured image shows the Magigoo bed adhesives. Photo via Magigoo.