Satellite Applications Catapult, leading the Business in Space Growth Network (BSGN) In-orbit Manufacturing Accelerator (IMA), has included two 3D printing companies, Photocentric and Deployables Cubed (DCUBED), at the top tier of the Accelerator.

Funded by the European Space Agency, the Accelerator is an initiative sponsored by ESA’s BSGN Industry Accelerator program. Through the BSGN program, the ESA enables private industries to actively engage, adapt their capabilities, and foster advancement for commercialization within the Lower Earth Orbit (LEO) economy. This initiative is in line with ESA’s objectives of accelerating the development of new in-orbit infrastructures and services. Over a rigorous 12-month program, the IMA collaborates with both companies, utilizing its multidisciplinary expertise and enabling the ecosystem to mitigate technology development risks. Consequently, the IMA lays the groundwork for in-orbit demonstrations and the commercialization of new methods.

Hamid Soorghali, Programme Lead for In-orbit Manufacturing Accelerator at the Satellite Applications Catapult, said, “The inclusion of both Photocentric and DCUBED mark a significant step forward in the Accelerator’s mission to advance in-orbit manufacturing capabilities and reinforce the collective strength of the European space industry. In addition to assisting technology development and commercialisation, we will work to strategically position innovators in the fast-evolving supply chain of this emerging segment filled with challenges and great opportunities.”

In-orbit Manufacturing Accelerator overview

Founded in February 2022, the In-orbit Manufacturing Accelerator, (formerly the Advanced Materials and Manufacturing Accelerator), is a Europe-wide multidisciplinary acceleration program. It initiates and co-invests in novel engineering solutions for in-orbit manufacturing, infrastructure development, and advanced materials developments utilizing microgravity R&D platforms.

Photocentric is currently engaged in the development of CosmicMaker, an LCD-based 3D printer tailored for use in space stations. This system possesses the capability to produce complex Silicon Carbide parts, thus making a “notable advancement” in the field of space manufacturing. Paul Holt, CEO of Photocentric Group, said, “By leveraging Silicon Carbide, we are enabling the on-demand production of a significantly broader range of vital space-grade tools, parts and components onboard space stations. CosmicMaker is designed to address the need for substantially greater resource effectiveness, operational efficiency and autonomy of in-orbit infrastructures.”

Holt further explained that working with the ESA’s IMA enables Photocentric to explore opportunities in the space sector, transfer its precision manufacturing expertise, and adapt its innovations for various in-orbit applications.

DCUBED will focus on advancing its robotic extrusion system to aid the production of large space structures in a vacuum. Thomas Sin, CEO and Founder, DCUBED, said, “Our collaboration with the IMA is perfectly timed as we ramp up focus and resources towards in-space manufacturing. Our solution aims to enable expansive infrastructure projects in space through the manufacture of large modular structures in orbit, whilst avoiding volume restrictions imposed by launch. A particular focus is on applications where greater performance is enabled by size, such as larger solar arrays for in-orbit power generation. DCUBED’s vision is to do big things in space. In space manufacturing is the disruptive technology that is needed to make this vision a reality.”

3D printing advancements in the aerospace sector

In-space manufacturing startup Orbital Composites (Orbitals) secured a $1.7 million U.S. Space Force contract for In-space Servicing, Assembly, and Manufacturing (ISAM) antenna development, funded by the Air Force Research Laboratory (AFRL). Collaborating with companies like Axiom Space, Northrop Grumman, and Southwest Research Institute (SwRI,) Orbital aims to transform Satellite-Based Cellular Broadband (SBCB) and Space-Based Solar Power (SBSP) applications for global internet access and clean energy. Orbital plans to launch its first Space Factory module in 3-5 years and signed an MoU with Virtus Solis for an MW-scale SBSP station, advancing SBSP technology.

Edinburgh-based rocket manufacturer Skyrora conducted full-duration testing to qualify its updated 3D printed 70kN rocket engine design, produced with Skyprint 2 3D printers, reducing production times by 66% and costs by 20%. This engine will power Skyrora’s first commercial orbital launch, featuring an enhanced cooling chamber for improved efficiency and engine longevity. Conducting these tests at its UK-based Midlothian test site, Skyrora achieved a significant milestone within its ESA contract for the Commercial Space Transportation Services and Support Programme, dubbed Boost. This effort contributes to reshoring the space industry in the UK and Europe, ultimately bolstering supply chains and nurturing growth within the UK space sector.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

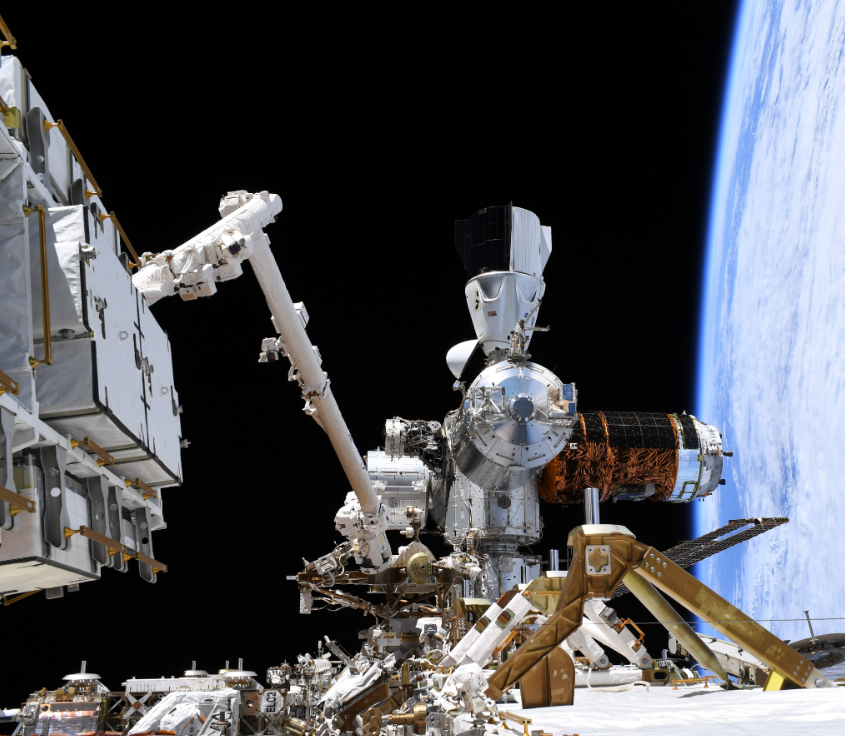

Featured image shows European Space Agency logo. Image via ESA.