When we write that 3D printing is not just a new technology as much as it is a new way to make things, all things, we mean it and we are fairly certain that we are going to see 3D printing get into a lot more sectors than it has thus far. One sector, for example, is that of sealed microfluidic devices, and the machine to 3D print them is Dolomite’s new Fluidic Factory.

Wikipedia describes microfluidics as “a multidisciplinary field intersecting engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology, with practical applications to the design of systems in which low volumes of fluids are processed to achieve multiplexing, automation, and high-throughput screening”. The field emerged in the 80’s (just like 3D printing) and Dolomite has been active within the field since 2005.

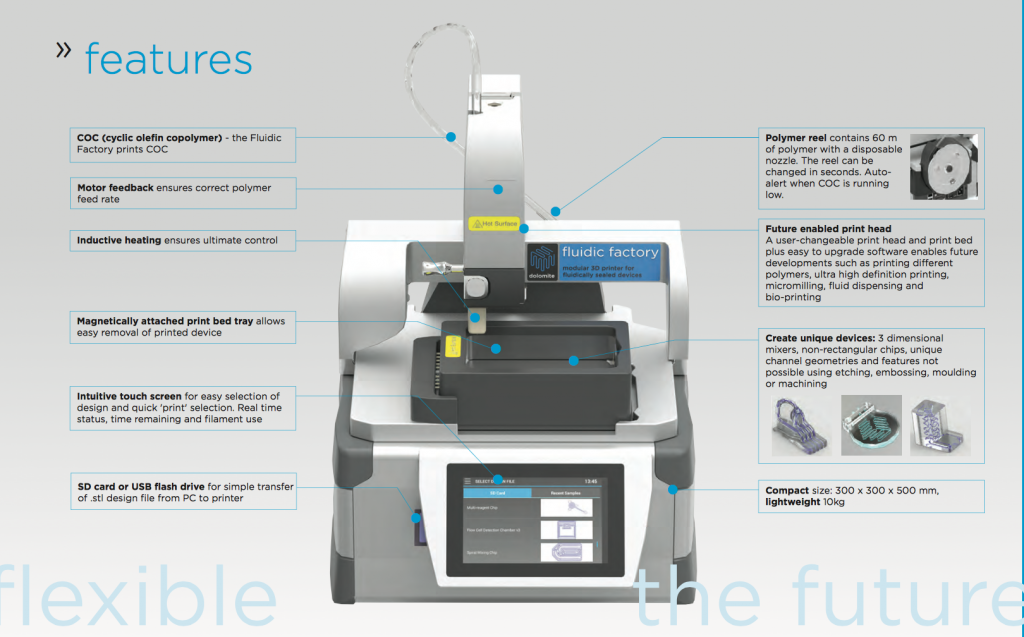

In fact, microfluidics seems like the perfect field for 3D printing. The Fluidic Factory is the world’s first commercially available device that enables researchers to design their own microfluidic chips, manifolds, connectors – or select them from the design library – and print them for as little as $1 per chip using FDA-approved, robust and translucent COC (cyclic olefin copolymer). The intelligent printer also ensures that the fluidic paths are completely sealed and features an upgradable print head, bed and software for future functionality as the technology progresses.

Along with the ability to create leak-free flow paths (as the hardware re-melts contact points ensuring sealing) the Fluidic Factory presents several more advantages inherent to 3D printing. These include the flexibility of creating original designs from any CAD software or selecting them from a wide range of devices in the design library. These can also have a greater geometrical freedom than standard microfluidic devices, including three-dimensional mixers, non-rectangular chips, unique channel geometries, and features not possible using etching, embossing, moulding or machining.

All that a fluidic technician or researcher has to do is insert the SD card, select the design, and press “Print” on the touch screen. Real-time status, time remaining, and filament use are displayed on the screen, while the the polymer reel can be replaced quickly and easily. The replaceable print bed trays also allow chips to cool while others are being printed. In other words it seems like a device that has the potential to disrupt the field of microfluidics, lowering costs and increasing the rate of innovation: this is something we will never get tired of repeating.