Massachusetts-based 3D printer manufacturer Desktop Metal (DM) has announced the acquisition of Belgian recoater system developer Aerosint.

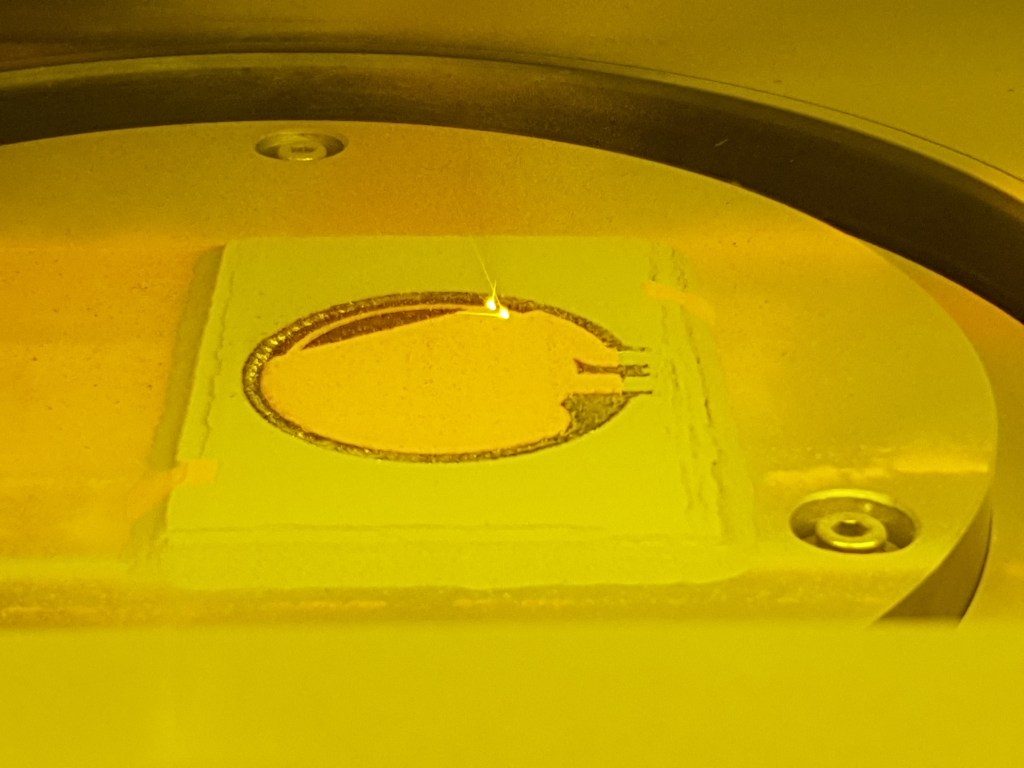

Using its patented Selective Powder Deposition technology, Aerosint is able to 3D print multiple materials simultaneously, unlocking powder efficiency, cost and part throughput gains. Having now bought the company, Desktop Metal intends to steadily integrate this multi-material process into its own offering, while allowing the firm to operate independently, albeit as a fully-owned subsidiary.

“This transaction advances our strategy to own differentiated print technologies that enable an expanding set of AM 2.0 applications at scale,” said Ric Fulop, Founder and CEO of Desktop Metal. “Today people print parts, but in the future, people will look to print full products, which may be composed of multiple materials. Multi-material printing is the next frontier in additive manufacturing.”

“Industrializing Aerosint’s core technology and related powder processing systems will provide many benefits to the broad adoption of AM solutions.”

Buying into multi-material AM

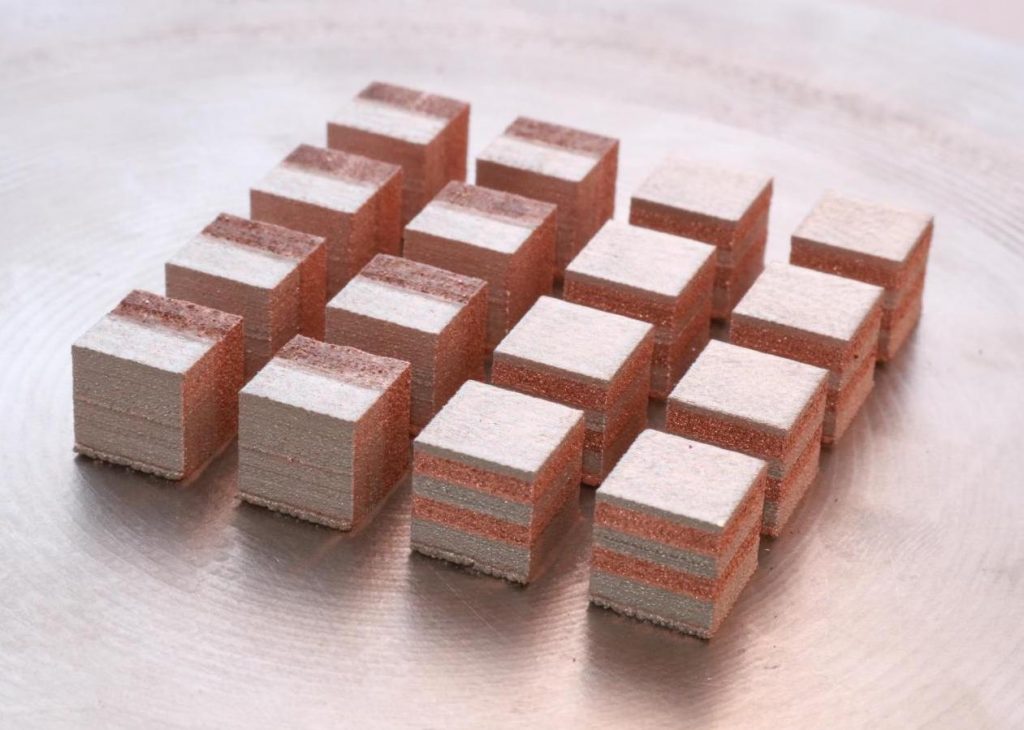

Since it was founded in 2016, Aerosint has iteratively developed a novel powder re-recoating system that’s capable of selectively depositing two or more powders into multi-material layers. Compatible with polymers, metals and ceramics, the firm’s technology enables the full three-dimensional control of placement during printing, and can be integrated into any LPBF, SLS, HSS or binder jetting setup.

Marketed as the only high-throughput, multi-material recoating system of its kind, Aerosint says that the technology offers reduced waste and lead times compared to conventional powder bed printing processes, and given that it allows users to locally optimize the mechanical properties of parts, it holds the potential to unlock new additive manufacturing applications.

Specifically, using Selective Powder Deposition, it’s possible to tweak the chemical and physical qualities of components to lend them enhanced wear resistance, vibration dampening and thermal or electrical conductivity. In certain molds, for instance, integrating cooling channels could help optimize their heat dissipation, while cutting tools can be made with a durable exterior but a highly-ductile interior.

Now that Desktop Metal has acquired Aerosint’s patented technology, it intends to run its subsidiary at arm’s length, leaving Co-founders Edouard Moens de Hase and Matthias Hick at the helm. Likewise, Aerosint’s product and service portfolio will continue to be made available to the wider industry, although they’re also expected to be integrated directly into Desktop Metal platforms within the next two years.

By adding Aerosint’s technology to its portfolio, Desktop Metal stands to advance its broader ‘AM 2.0’ strategy, and unlock new applications for its existing offering. For Aerosint, meanwhile, the deal provides it with access to a wider distribution network, which it says will allow it to “transform the AM industry and capture new market opportunities.”

“We are thrilled to partner with Desktop Metal to accelerate the execution of this vision, now with access to its scale, distribution network, and industry-leading AM 2.0 technology portfolio,” said Moens de Hase, Co-founder and MD of Aerosint. “We look forward to beginning a close collaboration with Desktop Metal while strengthening our ongoing efforts with our existing partners.”

“At Aerosint, we believe the future of AM is going to be multi-material.”

Desktop Metal and ‘AM 2.0’

Desktop Metal is known as a builder of binder jet 3D printers, but it changed course dramatically last year with its decision to go public as a $2.5 billion firm, and the roll-out of its ‘AM 2.0’ agenda. Since then, the company has embarked on an acquisition spree, with the aim of buying up “next-generation AM technologies that unlock throughput, repeatability and competitive part costs for mass production.”

Using the $580 million in funding raised via its merger with SPAC Trine Acquisition, Desktop Metal first bought EnvisionTEC for $300 million, in a deal that has improved its access to the dental, jewelry and bio-3D printing markets. A few months later, the company also acquired resin supplier Adaptive3D, allowing it to better support its Xtreme 8K line of DLP systems, and address the lucrative elastomers market.

In addition to buying into growth opportunities, Desktop Metal has also invested in expanding its own portfolio, rolling-out Desktop Health in March as well as its Forust wood 3D printing subsidiary in May 2021. While the former has already seen further expansion with the acquisition of eardrum bioprinting firm Beacon Bio, the latter is expected to yield sustainable new materials for Desktop Metal’s machines.

During Q1 2021, the company’s financials show that it spent a net $182 million on investment activities alone, and with its decision to snap-up Aerosint, Desktop Metal has now made it clear that it remains committed to its rapid expansion strategy, through which it intends to integrate more technologies that help scale the applications of its binder jetting portfolio.

“We look forward to partnering with our new colleagues at Aerosint to mature this unique technology and integrate it into upcoming Desktop Metal products over the next several years,” concluded Fulop. “We are also excited for Aerosint to independently continue its growth trajectory by offering Selective Powder Deposition solutions and services to third-party manufacturers and customers.”

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a multi-metal part being 3D printed using Aerosint’s recoater. Photo via Aerosint.