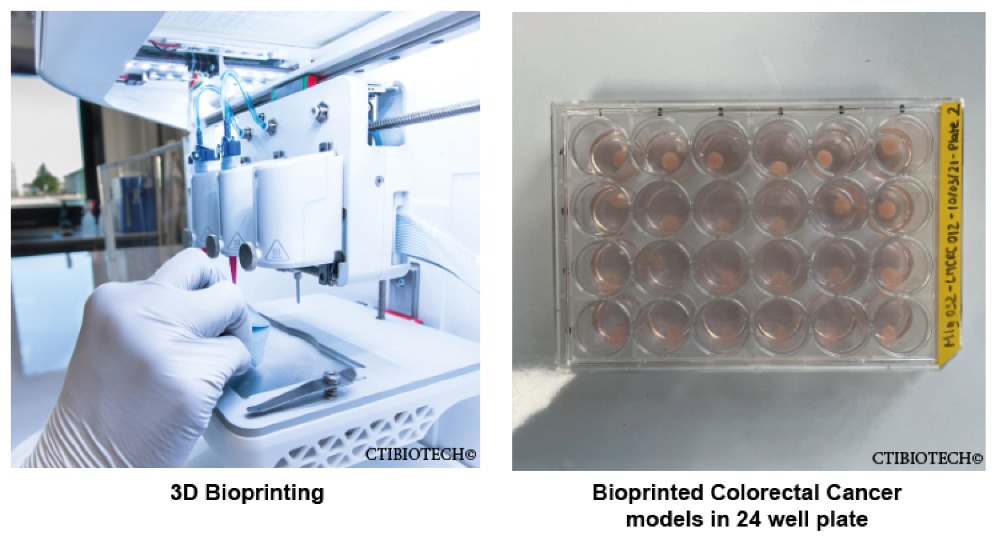

Regenerative medicine firm CTIBIOTECH has developed a new 3D bioprinting platform to deliver personalized medicine for patients with colorectal cancer.

Developed in partnership with the Medical University of Plovdiv and the UMHAT-Eurohospital in Bulgaria, the platform is capable of producing cost-effective and reproducible human colon cancer disease models and can also be used for chemotherapeutic screening.

“Advancement of cancer therapies requires new human models for drug testing,” said Professor Colin McGuckin, President and CSO at CTIBIOTECH. “Our 3D models provide, for the first time, accurate long-term testing strategies to help patients.”

CTIBIOTECH’s bioprinting technologies

One of CTIBIOTECH’s core aims is to reduce both the cost and time of drug development through developing 3D bioprinted human cancer models that can be used to determine the most effective treatment for individual patients. Over the last seven years, the company has been developing 3D bioprinting technologies in-house in order to expand its 3D tissue engineering capabilities for skin research.

CTIBIOTECH has previously worked with chemical firm BASF’s Care Creations arm to conduct research into 3D tissue models of human skin glands, and off the back of this began the development a 3D bioprinter capable of arranging sebaceous (skin) micro-glands into a dermatological model.

The firm has also partnered with Swedish 3D bioprinter provider CELLINK in the past to investigate new therapies for patients with cancer. The company used CELLINK’s machines to create tumurous tissue models in-lab, which it was optimistic could reduce the costly 40 percent attrition rate of pre-clinical drug screenings.

Most recently, CTIBIOTECH became the first in the world to 3D bioprint complete immunized human skin as part of the NOVOPLASM project. The company is supplying the project with hundreds of skin models to enable the consortium to validate its cold plasma wound healing technology for the treatment of infected burns and skin grafts.

Developing treatments for colon cancer

Colon cancer is the third leading cause of cancer, with more than 1.8 million new patients diagnosed each year around the world. The World Health Organization (WHO) predicts up to 12 million deaths in 2030 resulting from colon cancer, with poor prognoses for patients suffering from advanced forms of the disease.

However, according to the recent study carried out by CTIBIOTECH, the Medical University of Plovdiv and the UMHAT-Eurohospital, as little as 0.1 percent of all drugs make it from the lab to the hospital bedside due to high false-positive and false-negative rates of preclinical and clinical drug testing data.

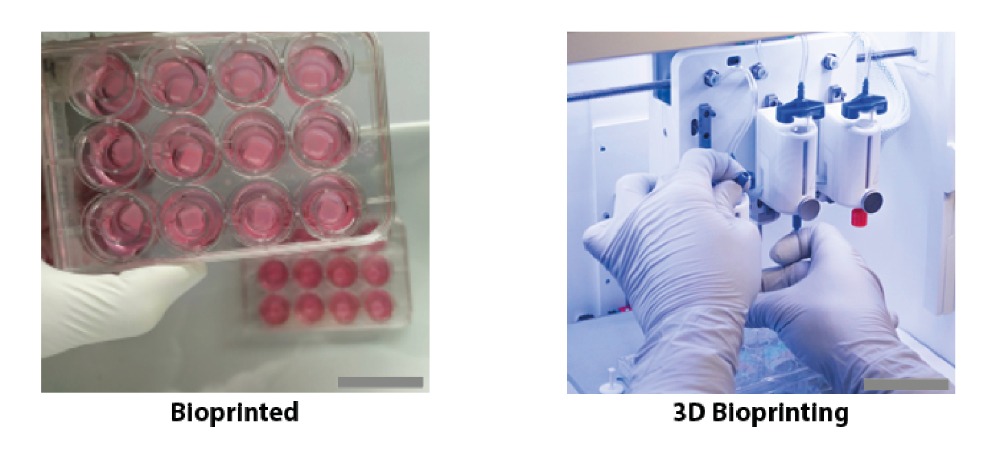

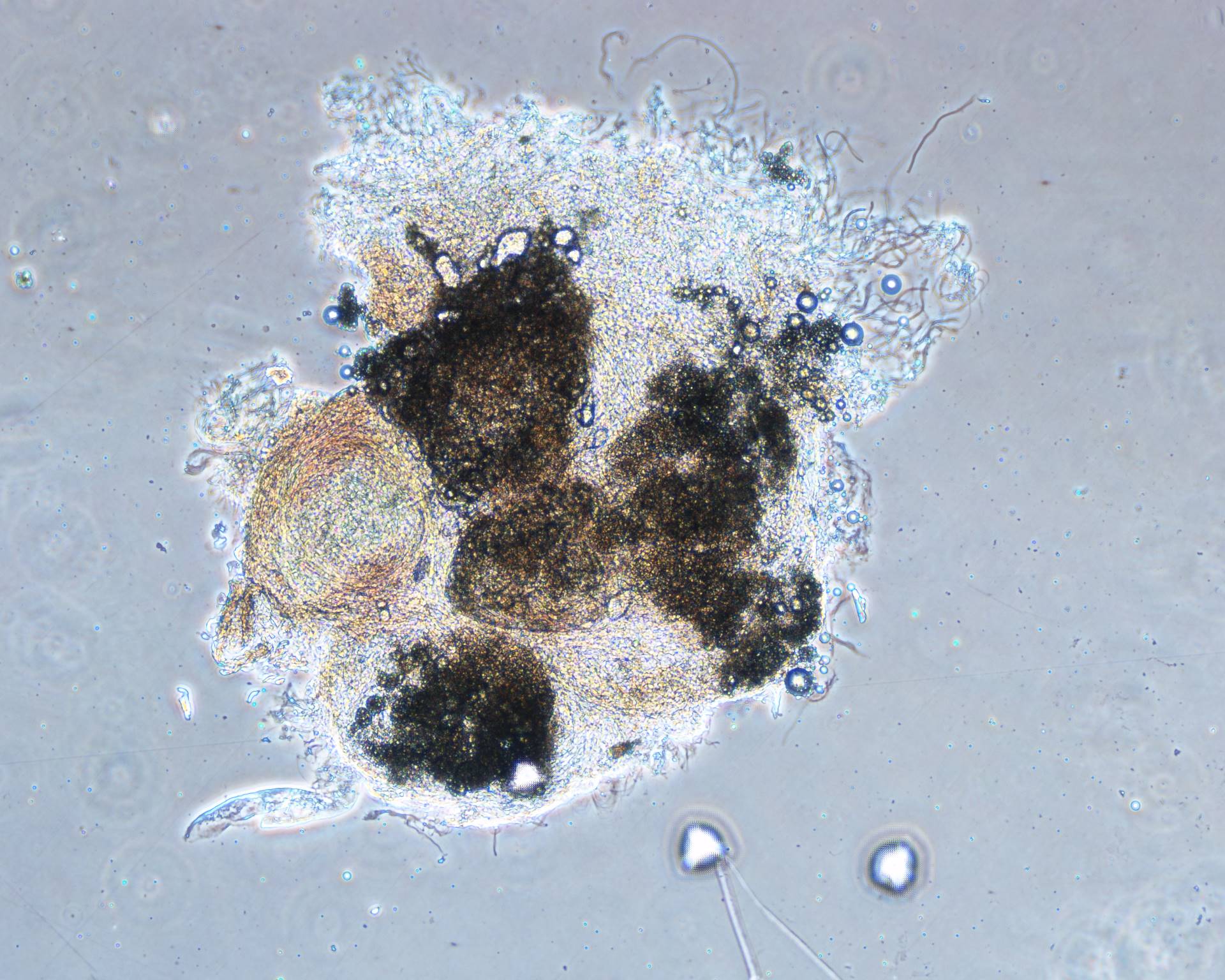

To address this, the partners set about developing a novel bioprinting platform capable of developing cost-effective, robust, and reproducible disease models which better resemble in-vivo carcinomas and offer greater opportunities for individualized therapies.

During the study, the teams produced 3D bioprinted “glandular-like” colon cancer tumors which demonstrated similar morphologies to patients’ tumors. To do this, the scientists leveraged CTIBIOTECH’s CTIBioTumour bioprinting technology to reproducibly identify the biomarkers of colorectal cancer and to model resistance to standard of care chemotherapeutics.

Improving personalized drug development

At present, the development of a new drug takes an average of 15 years and costs nearly €2.6 billion to reach the commercialization stage. Meanwhile, just 2 percent of molecules tested in the preclinical phase of drug development manage to reach the clinical phase, CTIBIOTECH says.

According to the company, its technology has the potential to reduce the time taken to develop new drugs by three years, while the time required for preclinical evaluation could be reduced from six years to two to three years. The CTIBioTumour platform could also reduce costs in the drug development chain by some 20 percent, reportedly saving up to €520 million per drug developed.

The company hopes its bioprinting platform will deliver a better assessment of the safety and efficacy of drug candidates, while also helping to implement personalized medicine platforms to better predict a patient’s response to different cancer therapies.

Further information on the study can be found in the paper titled: “A colorectal cancer 3D bioprinting workflow as a platform for disease modeling and chemotherapeutic screening,” published in the Frontiers in Bioengineering and Biotechnology journal. The study is co-authored by Y. Sbirkov, D. Molander, C. Millet, I. Bodurov, B. Atanasov, R. Penkov, N. Belev, N. Forraz, C. McGuckin, and V. Sarafian.

Advancing cancer treatment with 3D printing

With cancer deaths predicted to top 16 million by 2040, researchers and scientists are increasingly looking at how technologies like 3D bioprinting can aid diagnosis and drug development for cancer patients.

Lawrence Livermore National Laboratory (LLNL) has investigated how combining 3D bioprinting with computational flow simulations can provide a better understanding of how cancerous tumors are formed, while Washington State University has developed a soy-infused 3D printed bone-like scaffold capable of fighting off cancer cells.

Elsewhere, Korea’s Asan Medical Center has 3D printed surgical guides to aid breast tissue retention during cancer surgery, and 3D Systems and Collplant have partnered to develop 3D bioprinted soft tissue structures suitable for breast reconstruction treatments. Caltech and UC San Francisco scientists have also unlocked a new method of targeted cancer therapy using 3D printed ‘ChemoFilters’ which direct chemotherapy drugs towards affected organs.

One of the most significant breakthroughs in cancer treatments where 3D printing is concerned is the recent award-winning development by Tel Aviv University, concerning a 3D printed first-of-its-kind glioblastoma tumor using patient cells. The glioblastoma tumor model could improve the treatment of brain cancer by enabling clinicians to test the efficacy of new drugs in a realistic environment and speed up drug development.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows CTIBIOTECH’s bioprinting platform develops cost-effective, robust, and reproducible colon cancer models. Image via CTIBIOTECH.