Italian composite 3D printer materials manufacturer CRP Technology has revealed details of its technological partnership with Energica Motor Company in preparation for the 2019 FIM Enel MotoE ™ World Cup.

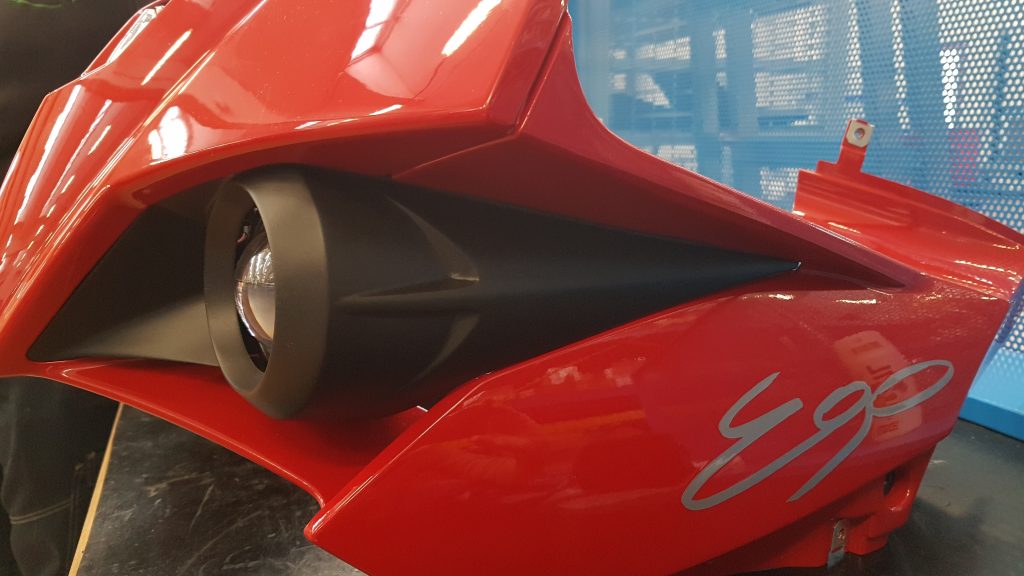

As the first MotoE World Cup for electric motorbikes, the Grand Prix will feature the participation of twelve teams from nine countries, all riding the Energica Ego Corsa. Though CRP has hinted at its development of this bike for sometime, this is the first time it has revealed the specific applications of Windform composite 3D printer materials in the vehicle’s development stages.

CRP Technology high performance fiber composite materials

CRP Technology together with CNC machining company CRP Meccanica form the CRP Group. Founded in 1970, the group is a well established figure in motorsport engineering and lead investor in the Energica Motor Company which was founded in 2014. CRP Technology is the group’s additive manufacturing division and was established in 1996.

“The original company was a mechanical engineering company doing CNC machining of motorsport parts and mechanical equipment,” explains Franco Cevolini, VP and Technical Director at CRP Technology, “Then when in 1996 I started to work inside the company, together with my father, we decided to study new technologies, and at that time we identified Selective Laser Sintering as the technology to explore for the manufacture of wind tunnel models for F1 instead of using subtractive technology.”

The company introduced its Windform XT carbon fiber composite SLS material in 2005. Now the CRP composite 3D printer materials range covers a selection of different carbon fiber filled and glass fiber reinforced polyamides, plus Windform FX BLACK, which is characterized by exceptional resistance to repeated bending and torsion. The material shows excellent impact resistance even at low temperatures. Its consistency and behavior are similar to polypropylene and ABS injection molded parts.

Each of CRP Technology’s materials are designed for high performance applications, producing end use components, small batch and pre-series part production, and functional prototyping, namely: assembling, fitting, functionality and performance tests.

3D printing for fast turnaround and quick corners

Also hailing from Italy, Energica Motor Company is a specialist manufacturer of electric motorbikes. It’s first generation bike, the Energica Ego became Italy’s first street-legal electric motorcycle in 2011, and featured CRP Windform 3D printed parts.Chain sliders, motor terminal cover, instrument support, headlight covers, side fairings and others were all 3D printed by CRP Technology for this model, using the company’s Windform composite materials.

An upgrade of the landmark Energica Ego cycle, the Energica Ego Corsa likewise has been developed in part with Windform 3D printed components .Using Windform GT, a polyamide based glass fiber reinforced composite material with high elasticity and resistance to impact, parts including the motor terminal cover was 3D printed by CRP Technology. Water pump supports and others parts were manufacturing using Windform RL, a durable composite elastomer with high sealing power and flexibility.

In the Ego Corsa bike’s racing redesign, the front & rear fenders, fairing, seat and tail were also aerodynamically developed using Windform XT 2.0 and Windform SP. By 3D printing functional prototypes of these parts, the Energica team were able to test ride the Ego Corsa at TT Circuit Assen. Using feedback from this test, the team could then ergonomically modify the parts with a quick turnaround.

According to Energica technical staff, “This fairing is not only more aerodynamic, but it also has a smaller frontal and lateral section. These improvements led to achieve increase in terms of performance and they led to achieve greater manageability in fast corners,”

“The Windform® XT 2.0 has once again proved to be a high performance composite material. We are very happy how the 3D printed new fairing behaved during the tests.”

Following the proof of design in Windform materials, the parts have now been created as pure carbon fiber parts. The next stage for the Energica Ego Corsa will be racing the Grand Prix stages of the MotoE World Cup which begins May 5th.

Led by CRP Technology SLS innovation

SLS at CRP Technology is conducted by eight 3D printers, most of which are provided by 3D Systems, e.g. the Sinter Pro 140 and six Vanguard HS SLS machines. The department also includes the RICOH AM S5500p. Many auxiliary systems in the workshop are self made by the CRP Technology team, highlighting the company’s key commitment to providing complete solutions for the most demanding industrial sectors. Cevolini explains:

“We’ve always invested in technological innovation, and we will be always doing it.”

In addition, the VP and Technical Director adds that “a new production printer will be arriving,” at CRP Technology soon, “and it will be able to process the composite materials of the future with exceptional performance.”

For updates on CRP Technology’s progress with the MotoE World Cup and its future production printer the company is inviting readers to subscribe to the CRP and Windform newsletter, and visit CRP Technology.

Is this an award winning story? Nominate CRP Technology, Franco Cevolini, Windform composite materials and more for the 2019 3D Printing Industry Awards.

For all of the latest additive manufacturing news, subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. Create a profile on 3D Printing Jobs to find new opportunities near you.

Featured image shows a test ride of the Energica Ego Corsa. Photo via CRP Technology