CRP Technology, an Italian materials manufacturer, has announced that its proprietary Windform line of materials will not be available to 3D printing service bureaus anymore.

On the formation of the new strategy the company stated, “The aim of CRP Technology is to ensure the highest quality in the manufacture of 3D printed components in Windform.”

“For this reason, the company has revised its commercial policy: Windform composite materials will no longer be sold to service bureaus for the toll-manufacture of 3D printing components.”

In the race for additive

Founded in 1970, CRP Technology together with CRP USA, CRP Meccanica, and electric motorbike manufacturer, Energica, comprise the CRP Group Network.

The original company began as a mechanical engineering company which produced parts for the motorsport’s companies. Now, the CRP Group has a strong presence in the automotive industry and is especially active in motorsports. For example, CRP USA is based in North Carolina where NASCAR is headquartered.

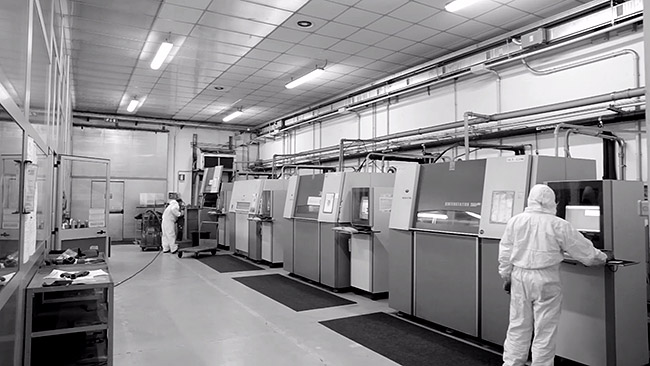

Furthermore, CRP Technology’s additive manufacturing portfolio includes a range of 3D printing materials and its Rapid Prototyping Department houses more than twenty-five 3D printers from 3D Systems, RICOH, and other industrial manufacturers.

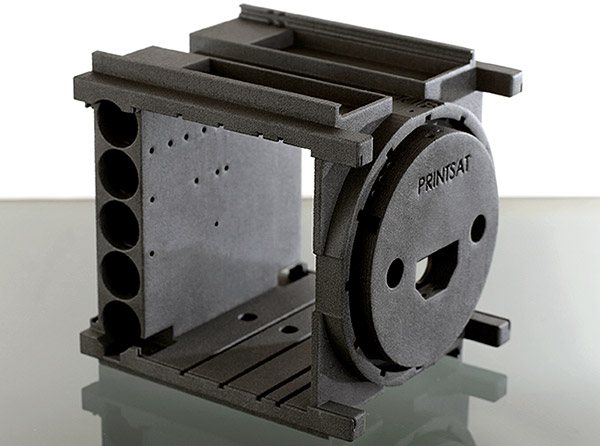

Windforming prototypes

Windform is an ISO 9001:2015 certified SLS 3D printing material ideal for functional prototyping. Since the introduction of the Windform brand, seven variations of the material have been released, six of which are polyamide-based and one is an elastomer.

Windform materials have been used in the aerospace, automotive, and medical industry. An example of such application is the generative orthodontic which CRP Technology produced using the Windform GT, a polyamide-based fiberglass reinforced material.

In addition to being 3D printable, Windform materials are also available for CNC machining.

A new strategy

Although, Windform material is no longer available to 3D printing service bureaus CRP Technology has said that the material will be available to purchase for original equipment manufacturers (OEM).

According to the company’s latest announcement “The increase in production capacity both in Europe and in the United States will guarantee each customer the volumes necessary to satisfy any request from all over the world, in compliance with the high standards of service and quality that has always been a distinctive element of CRP Technology and CRP USA’s activities.”

Furthermore, CRP Technology and CRP USA will continue to 3D print parts for their clients with the Windform materials.

To learn more about additive manufacturing, subscribe to our 3D printing newsletter. For live updates, you can also follow us on Facebook or Twitter.

We also have jobs in the industry, visit our 3D Printing Jobs page to learn more.

Featured image shows flexible Windform RL. Image via CRP Technology.