The Tokyo Institute of Technology and C-MET, Inc. led by Daicho and his adviser Shoji Maruo have sought to develop a new conductive, moldable, 3D-printable resin. The premise of the new resin is the promise of manufacturing customized electrodes for fuel cells, batteries and a myriad of other application.

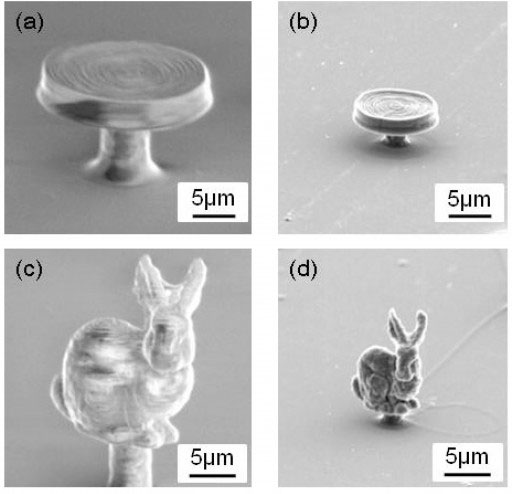

Two microstructures ‘3D-printed’ using using two-photon polymerization in RDGE material:

Left: Pre-carbonization. Right: After

The research team, which includes physicists and chemists from Yokohama National University have presented their results in an open access paper.

Researchers currently have access to materials that can be used to make complex 3D structures, but commercially available resins do not respond to carbonization, an innate part of the process to prepare electrodes.

Carbonizing to induce conductivity requires extreme heat, which unfortunately also destroys the resin’s shape.

In response the team have developed Resorcinol Diglycidyl Ether (RDGE), typically used to dilute other resins but never before extant, with the advantage that it is liquid, therefore may be sculpted.

In addition to crafting pyramids and discs, the researchers reproduced the well-known standard ‘Stanford bunny,’ which is commonly used in 3D modeling and computer graphics (CG). Maruo says that when he first saw a picture of the rabbit structure taken with the SEM, he was delighted at the structural integrity. He said:

“When we got the carbon bunny structure, we were very surprised, even with a very simple experimental structure, we could get this complicated 3D carbon microstructure.”

The process is quicker, cheaper and easier. Next Maruo the team intend to push the temperature envelope, turning the surfaces into graphite, a higher-quality conductor than the carbonized surfaces they have created so far.