Continuous Composites, a developer of composite 3D printing technology, has been awarded a $750,000 Phase II Small Business Innovation Research (SBIR) contract from the Department of Defense (DoD).

The company will use the capital to demonstrate its proprietary Continuous Fiber 3D Printing (CF3D) technology in a collaborative manufacturing project with the Air Force Research Laboratory (AFRL). Together, the organizations will work to 3D print multifunctional composite wing structures for attritable (low-cost, disposable) unmanned aircraft.

“A Direct to Phase II program provides us the opportunity to collaborate with this innovative team and their disruptive manufacturing technology to further develop CF3D’s capabilities for mission readiness,” says Craig Neslen, AFRL Manufacturing Lead. “We are committed to evaluating and maturing Continuous Composites’ technology for advanced aerostructures which will enable us to meet the challenging manufacturing demands of the DoD.”

CF3D for defense applications

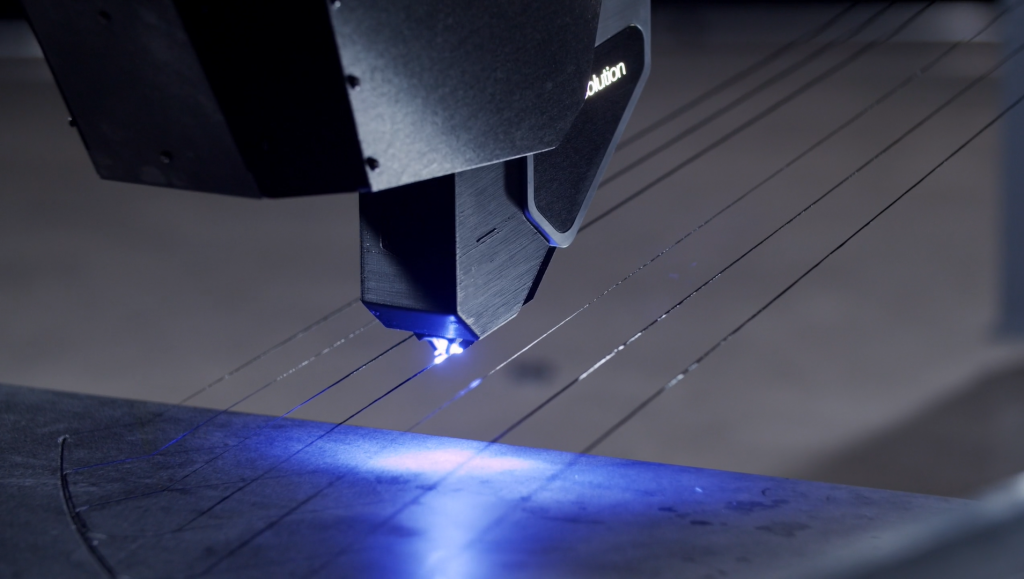

Continuous Composites was established back in 2015, and the Idaho-based company claims to have one of “the world’s earliest granted patents on printing with continuous fibers”. Unlike many other composite printing processes, CF3D works by combining continuous fiber reinforcements with thermosetting resin technology. Mounted onto the end of a robotic arm, a CF3D end-effector is used to co-deposit dry fibers alongside a rapidly curing polymer resin matrix.

The resin-infused fiber is cured almost instantly under a UV light, producing an anisotropic part with customizable strength properties. CF3D is compatible with a whole host of fiber types, including carbon, glass, optical, and metallic.

In the context of defense applications, the 3D printing technology provides a low-cost, time-efficient method of fabricating lightweight, topologically optimized structural components. These advantages directly align with the Air Force’s Low-Cost Attritable Aircraft Technology/Platform (LCAAT/P) initiatives.

“We are honored to receive this Phase II SBIR Contract directly through the Department of Defense,” adds Tyler Alvarado, CEO of Continuous Composites. “The AFRL is a long-standing customer who recognized early the disruptive capabilities of CF3D. Through this contract and others, we are committed to transforming DoD Operational Capabilities.”

The Phase II SBIR contract

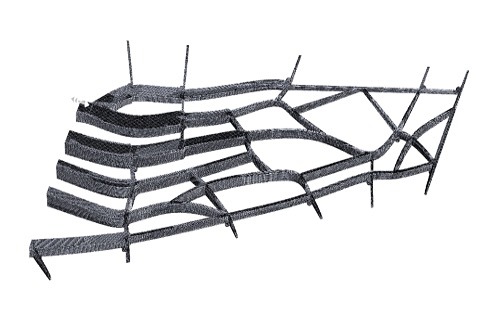

The contract itself is concerned with 3D printing an integrated wing spar and rib configuration in a single monolithic wing frame. Before printing, Continuous Composites and AFRL’s Advanced Structural Concepts division will use AI-based generative design software to optimize the geometry of the wing structure. The part is set to be fabricated using a high-performance thermoset resin reinforced with continuous carbon fiber – materials which have been developed in collaboration with materials specialist Arkema.

Once fabricated, the 3D printed frame will be assembled with a composite wing skin, which will make it suitable for use on an unmanned aircraft. AFRL will also perform a static wing test to evaluate the structure’s performance, while Continuous Composites will document process data to compare its 3D printing technology to traditional fabrication and assembly processes.

Composite 3D printing technology like CF3D provides a wide variety of benefits when it comes to costs, lead times, and part properties. Earlier this month, Continuous Composites also partnered with energy technology firm Siemens Energy to 3D print power generator parts. Using CF3D, the companies were able to manufacture the generator components using a special thermoset glass fiber-reinforced polymer material.

Elsewhere, 3D printer manufacturer Impossible Objects recently entered a joint development agreement with Owens Corning, a provider of industrial building materials, to develop its own specialized composite materials for 3D printing. Set to be used with Impossible Objects’ composite-based additive manufacturing (CBAM) process, the fiberglass-reinforced materials will reportedly offer high strength-to-weight ratios and excellent chemical resistances.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the XQ-58A Valkyrie drone, an example of a ‘low-cost’ attritable aircraft. Photo via Kratos Defense.