With plans to expand the use of 3D printing, GE Healthcare has opened its first specialist 3D printing lab in Europe.

The Innovative Design and Advanced Manufacturing Technology Center for Europe, is located in Uppsala, Sweden. 3D Printing Industry asked Andreas Marcstrom, Section Manager of Additive Engineering at the Uppsala site a few questions to learn more.

The GE Healthcare center will use technologies including 3D printing and robotics to speed up the launch of new innovative products for the healthcare industry.

Working alongside the metal additive manufacturing equipment and polymer 3D printers are collaborative robots. GE Healthcare describes these as “cobots”. The Uppsala site also features traditional machining equipment.

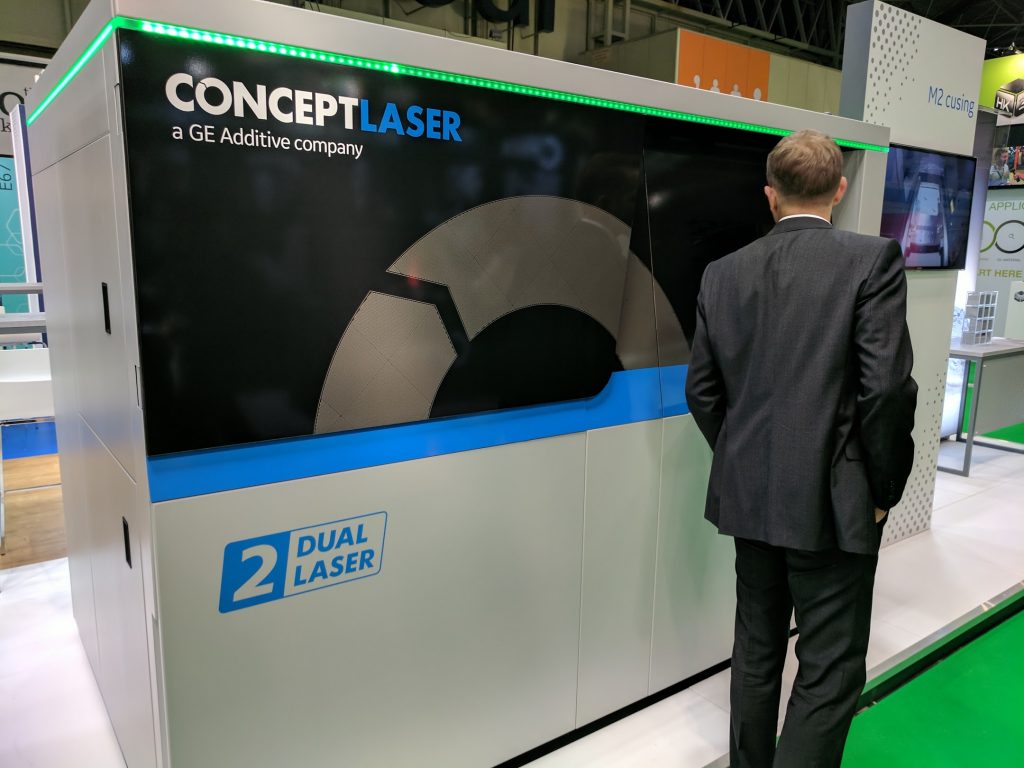

Andreas Marcstrom explains, “The center contains two industrial grade printers: a GE Additive Concept Laser M2 printer and a polymer printer as well as several collaborative robots or “cobots”.”

For GE Healthcare, a core part of realizing the advantages of 3D printing is “ensuring the technology is considered at the start of the innovation process with Research and Design teams working with advanced manufacturing engineers and in collaboration with customers.”

Uppsala site to receive significant annual investment

Although GE Healthcare has not disclosed the value of the investment in the European 3D printing and design center Marcstrom says, “GE has committed to spending $70 million each year between 2017 and 2022 to “significantly” increase the capacity of the GE Healthcare Life Sciences facility in Uppsala.”

Sweden is also the home-country of GE Additive acquisition Arcam, manfacturers of Electron Beam Melting additive manufacturing systems.

Marcstrom explains that Uppsala was chosen for the advanced lab because, “In Uppsala, you are at the heart of the biggest R&D organisation within GE Healthcare’s Life Sciences business.”

“At the same facilities, you have teams with post-processing expertise as well as Global Supply Chain. And close by, in Umeå (Northern Sweden) you have the manufacturing site for the hardware side of the GE Healthcare Life Sciences’ BioProcess business. Teams from all these areas of expertise will collaborate on projects at the center and ensure additive is considered right at the start of product design.”

Using 3D printing to research biopharmaceutical production

GE is also working with the biotechnology company Amgen and will test the performance of a chromatography column, used in the complex process to develop biopharmaceuticals. The range of drugs under investigation will be used to treat diseases including cancer and immune diseases.

A custom-designed 3D printed column is currently undergoing tests to assess suitability for Amgen’s research “to help develop improved processes for the purification stage of biopharmaceutical production.”

Marcstrom says that re-thinking the design process is a further advantage of additive, “GE recognises that the flexibility of additive means the technology is enabling product designs that could not be achieved with traditional manufacturing.”

“Additive manufacturing is already improving manufacturing efficiency in the healthcare industry. Across supply chains, single 3D printed parts are replacing multiple, complex, expensive parts offering technical improvements, waste reduction and cost savings.”

Addressing the healthcare market has proven a successful strategy for a number of 3D printing enterprises. U.S. based 3D Systems has an impressive healthcare facility in Littleton, CO.

During a tour of the 3D Systems Healthcare Technology Center, I saw first hand how such centers of excellent can produce remarkable achievements. For example separation of conjoined twins Jadon and Anias McDonald who underwent a landmark 27 hour surgery, aided by 3D printing.

Healthcare revenue at 3D Systems grew by 27% for Q1 2017 and increased 25% during Q2, reaching $49 million – almost a third of all revenue for the quarter.

For all the latest news about 3D printing healthcare applications, follow our social media accounts and subscribe to our free newsletter.

Featured image shows a Concept Laser M2 Cusing metal additive system. Photo by Michael Petch.