Italian professional 3D printer manufacturer Roboze has confirmed that CNH Industrial, one of the world’s largest capital goods companies, has selected its systems to help automotive client Iveco.

Installed at Iveco’s assembly plant in Suzzara, Northern Italy, the Roboze One+400 3D printer is being applied to the production of jigs and fixtures for the Iveco Daily line of light commercial vans.

High viscosity polymer 3D printing

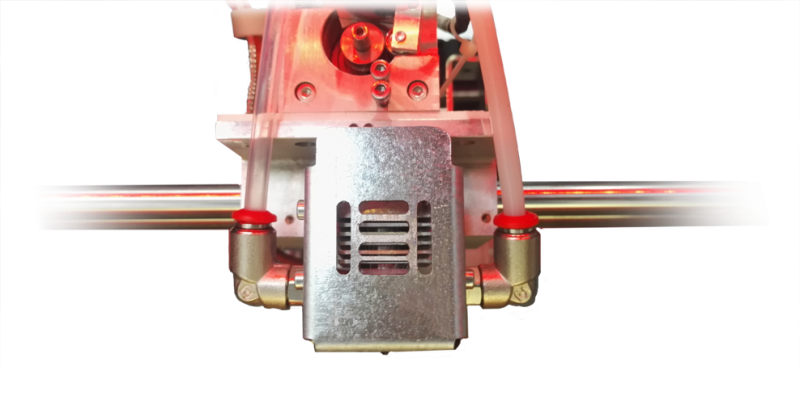

Roboze’s specialty is in the production of high viscosity polymer (HVP) extruders, and beltless FFF 3D printing. Its HVP extruder range is patent pending, designed to maximize the printing speed of high performance, and high temperature polymers such as PEEK. With beltless 3D printing, the company minimizes mechanical vibrations that can cause imperfections in 3D prints and boosts precision through a hardened steel rack and pinion.

Making use of both of these technologies, the Roboze One+400 is capable of extrusions temperatures up to 500°C. It has a build volume of 300 mm x 200 mm x 200 mm (X x Y x Z) and, at present, it has been optimized for use with nine technical materials including CARBON PA and ULTEM™ AM9085F, a feature that became a deciding factor in CNH’s selection of the system.

Iveco Daily vehicles

As a former part of Italian automotive company Fiat, Iveco has been active in the industry for over 150 years. The Daily series of vans, the subject of this recent Roboze case study, is the company’s longest-running vehicle production series, first introduce to the market in 1978.

Now in its sixth generation (2014 – present) the Iveco Daily series encompasses three body styles, (vans, minibuses and pickup trucks) with as many as 11,000 product variations.

The Iveco plant in Suzzara is responsible for the company’s entire output of Iveco Daily vehicles.

3D printing for jigs and fixtures

In what has been an award winning application for some companies in the industry, the Roboze One+400 is used at Iveco Suzzara is used to produce lighter, more cost-effective tools for vehicle assembly.

Grazia Cappiello, engineer at the Manufacturing, Equipment & Tooling department at Iveco parent company CNH Industrial, comments “We decided to invest in the Roboze One+400 among other solutions of the same kind because it allows us to choose a wide range of technical materials and consequently permits to realize equipments that can be used in contact with paints or in ovens that can reach very high temperatures,”

“Moreover,” Cappiello adds, “Roboze’s materials can be used in direct contact with aesthetic parts of the vehicle, not releasing any residues and/or abrasions.”

The Roboze One+400 has now been in service at the site for one year, and Roboze is planning a webinar to further discuss its application at Iveco. Ilaria Guicciardini, Marketing Director at Roboze, adds, “Working with Roboze 3D printing solutions today means creating critical competitive advantages in a medium-long term,”

“Speeding up the response to market with, at the same time, a significant reduction of manufacturing costs becomes possible and accessible. The CNHi case is a tangible evidence.”

Nominate Roboze, its 3D printers, CNH Industrial, Iveco and more in the 2019 3D Printing Industry Awards.

For all the latest automotive applications and 3D printing news subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows inside the Roboze One+400. Photo via Roboze