A unique 3D-printing application is playing a pivotal role in helping a spring ring manufacturer to shave weeks off lead times and deliver hugely increased product volumes to meet growing customer demand.Last year, West Yorkshire-based Cirteq made around 700 million circlips and retaining rings, exporting them across the globe to more than 500 customers spanning the aerospace, automotive, rail and sustainable energy sectors.

Used in engine construction to stop something coming out of a bore or to keep something on a shaft, Cirteq’s 3,800 product variants are made to the exacting specifications of OEMs including Jaguar Land Rover, Volvo, Honda, GKN, Bosch, Siemens and Mitsubishi.

To enable the business to continue to deliver quality parts in such high numbers, it identified 3D printing as an assistive technology – and it has now become an integral part of its ongoing success.

Cirteq Customer Quality Liaison Manager Theo Speller said: “We were trying to link processes and equipment in a production cell via ancillary equipment that really moved products from A to B, and it needed to get them there in a minimal time and also add some value.

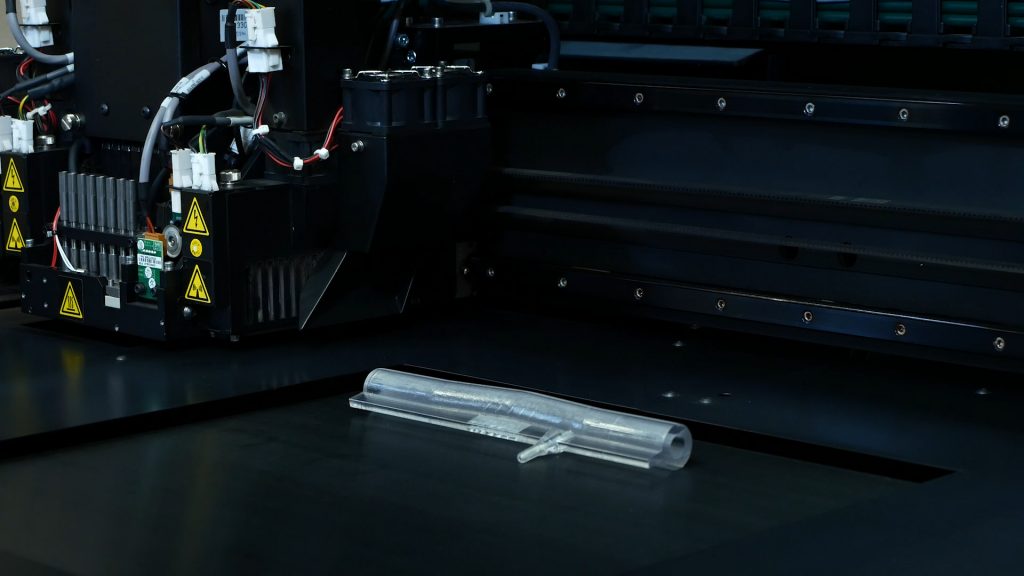

“What we’ve printed are rails that not only deliver the parts to the next process, but in some stages can actually oil the parts as they’re moving, say from a sorting bowl to an oiling station, or from an oiling station to a packing station.

“We’ve taken away a stage that required a lot of manual labour. One person can now do the job that it traditionally took four people to do, and we’ve reduced the footfall from walking across the factory to getting the finished component in a fraction of the time and a fraction of the cost.”

Cirteq uses a Stratasys Objet350 Connex3 machine, supplied by Stratasys UK platinum partner SYS Systems.

The first system in the world to simultaneously 3D-print multiple colours and materials, the Connex3 allows users to create models with the look, feel and properties of real production parts, as well as quickly and easily print off custom jigs, assembly fixtures and tooling with ultra-fine accuracy and without any major post-processing requirements.

Multiple materials can be loaded at one time, enabling the printing of parts that require a range of mechanical, optical or thermal properties like non-slip grips, transparent windows or flexible hinges. Mr Speller added: “Being able to print to an exact design means that when that plastic print is finished it fits into the exact space it was designed for.

“You can basically press the start button and then just walk away, and when you come back that finished component has been built in a fraction of the time it once took to build and without any direct labour, leaving the person that programmed it free to work on other development projects.

“After two years we’ve seen no significant wear on these collection rails and we’ve passed literally millions of spring steel rings over them in that time. That’s come through specialist knowledge from SYS Systems to advise us on the correct plastic for the application that we required.

“I can see that this print system could be applied to a wide range of industries and has two immediate benefits – one, it will save you time in getting your parts from A to B and two, it will offer you greater accuracy if you can take a CAD model of something and print that exact CAD model.

“Then you’ve got an accurate solution.”

Video of the process is available here.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.