Ceramic specialist CeramTec has successfully produced a new generation of ceramic sample containers for a space experiment facility on the International Space Station (ISS), as part of a project consortium with the likes of Airbus Defence & Space and the European Space Agency.

The containers, which started their journey to the ISS on the SpaceX-22 in June, will be used to facilitate the precision measurements of certain thermophysical properties of metals, alloys and semiconductors, which are not possible on Earth.

The goal of the research is to expand our understanding of the early phases of how material structures are formed in order to improve production and casting processes here on Earth.

CeramTec’s technical capabilities

Having developed, manufactured, and supplied technical ceramics for more than a century, CeramTec is a global leader in this field. With a product offering numbering more than 10,000. The company’s products are used within a wide variety of industries ranging from medical engineering and automotive, to electronics, energy, and environmental engineering, to name just a few.

While much of CeramTec’s portfolio isn’t directly related to 3D printing, the firm recently highlighted the importance of product diversification in the release of its FY 2020 financials, partly due to several upcoming international projects concerning its 3D printing activities.

The firm has already made inroads into the 3D printing sector this year, having launched its ROCAR 3D printing powder which supposedly has similar properties to silicon carbide, and released its CeramCreator tool to help customers simplify their process chains and shorten their quotation processes.

Last month, CeramTec successfully tested the cooling capabilities of its new e-mobility power semiconductor module developed in partnership with Fraunhofer IISB. The firm’s latest ceramic product is designed to thermally regulate the drive inverters of electric vehicles.

Developing sample containers for space

CeramTec has been working with Airbus and the other partners in the project consortium to produce sample containers for experiments as complex components, manufacturing them at its Plochingen site in Germany.

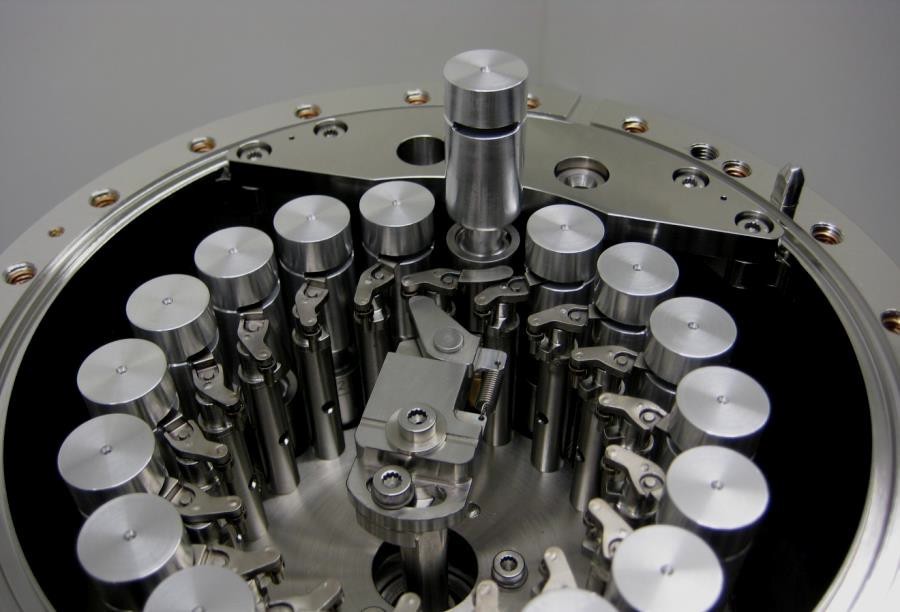

First installed in the ISS back in 2017, the pot sample holders and cage sample holders are made of silicon nitride and are used in the station’s Electric Magnetic Levitator (EML), a multi-purpose research facility for natural science experiments.

Within the EML, the sample containers are placed into a coil within which metal alloy samples are fixed around in a contact-free manner by electromagnetic fields while suspended in zero gravity.

Now, the consortium has produced a new generation of sample containers manufactured from silicon nitride. The ceramic material is particularly suited to this purpose thanks to its non-existent electrical conductivity which prevents external influences on the measurements. The material also features the required high heat resistance to withstand the temperatures of the measurement cycles, which take place between 500 and 2,100 degrees celsius.

The samples are melted, cooled in their liquid state and then solidified again to enable precision measurements of certain thermophysical properties of metals, alloys, and semiconductors that are not possible on Earth. This enables the ISS team to analyze the early formation of material structures in order to expand our knowledge of transition processes, atomic structures, and material properties.

Ultimately, it is hoped that the material properties measured in space will enable us to improve production and casting processes on Earth. The knowledge gained during the experiments will be used to increase the quality of these processes while reducing the cost of high-tech castings, therefore allowing manufacturing methods to be refined and materials and products to be improved and redeveloped.

CeramTec’s latest generation sample containers began their journey to the ISS on the SpaceX-22 in June, and will “significantly support further research activities” carried out in space, the company said.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the sample chamber with sample holders. Photo via Airbus.