In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a novel ceramic printing material, 5G-capable additive antennas, a $90 million public offering, fabricated parts for both bikes and boats, and an appetite-testing plate of 3D printed vegetables.

Read on for the most recent updates from Renishaw, Allevi, SWISSto12, CeramTec, ROBOZE, GoEngineer and more.

Nexa3D and Allevi launch upgrades

Starting this week with system updates, 3D printer manufacturer Nexa3D has launched a new interface layer technology that extends the working life of NXE400 membranes. The Everlast Membrane is made from a highly-durable and resilient substrate, potentially making it last 25 times longer than other vats or trays.

The new technology is designed to process over 50,000 layers before being changed, allowing users to spend less time swapping membranes, and engage in more continuous production runs. The Everlast doesn’t compromise on quality either, and Nexa claims that it improves the surface finish and dimensional accuracy of every part produced.

“3D print manufacturers seek every possible advantage to keep their workflows moving as fast and efficiently as possible while maintaining consistent production standards,” said Michele Marchesan, Chief Growth Officer of Nexa3D. “Everlast Membranes give them yet another edge to provide longer, uninterrupted production runs.”

Elsewhere, 3D bioprinting company Allevi has released a new High Temp Print Head for use with its proprietary Allevi 1 and 3 biomedical machines. The extruder is specifically designed to work at temperatures up to 255˚C, allowing users to 3D print parts out of PLA, PLGA, ABS, PCL, polystyrene and custom composites.

By attaching the device onto the magnetic print head carriage of an Allevi system, adopters can now access a range of applications including prototyping, bone modeling, creating biomedical devices and 3D printing dental implants. According to the firm, its extruder comes with “all the accessories users need” to “bring their research up a notch.”

Aerospace advances from Farsoon and SWISSto12

Civil antenna and terminal solution provider Rhosoon has utilized Chinese 3D printer manufacturer Farsoon’s 403P machine to fabricate a vehicle-mounted 5G antenna system. Adopting 3D printing in the design, prototyping and optimization of the devices allowed Rhosoon to make them lighter, smaller and simpler than before.

The upgraded system features Luneburg lenses with decreased index refraction from the center to the surface, enabling them to more effectively relay multiband signals. What’s more, using Farsoon’s SLS technology, Rhosoon was able to 3D print the devices in one piece without any supports, and with superior mechanical qualities to previous designs.

“Farsoon LPBF technology has saved us so much investment cost that was required for production tools and molds,” stated a Rhosoon representative. “We can achieve 48 high quality pieces production per day on a single Farsoon 403P machine. It is a perfect solution for economic small batch fabrication and spare parts.”

In other radar-related news, Swiss radio frequency (RF) specialist SWISSto12 has been contracted by CubeSat manufacturer Fleet Space Technologies, to create its first all-3D printed patch antennas. Utilizing its patented production process, SWISS intends to deliver robust high-performance devices that are both compact and lightweight, which will then be launched into LEO and attached to a small satellite.

“SWISSto12 is excited to collaborate with Fleet Space to deliver the antennas for the powerful comms nanosatellite in LEO with each nanosatellite having the capacity to connect to tens of thousands of gateways,” said Dr. Emile de Rijk, Founder and CEO of SWISSto12. “3D printed RF products with our patented manufacturing technology allow our customers to push the limits further”.

New materials from BCN3D, CeramTec and AGC Chemicals

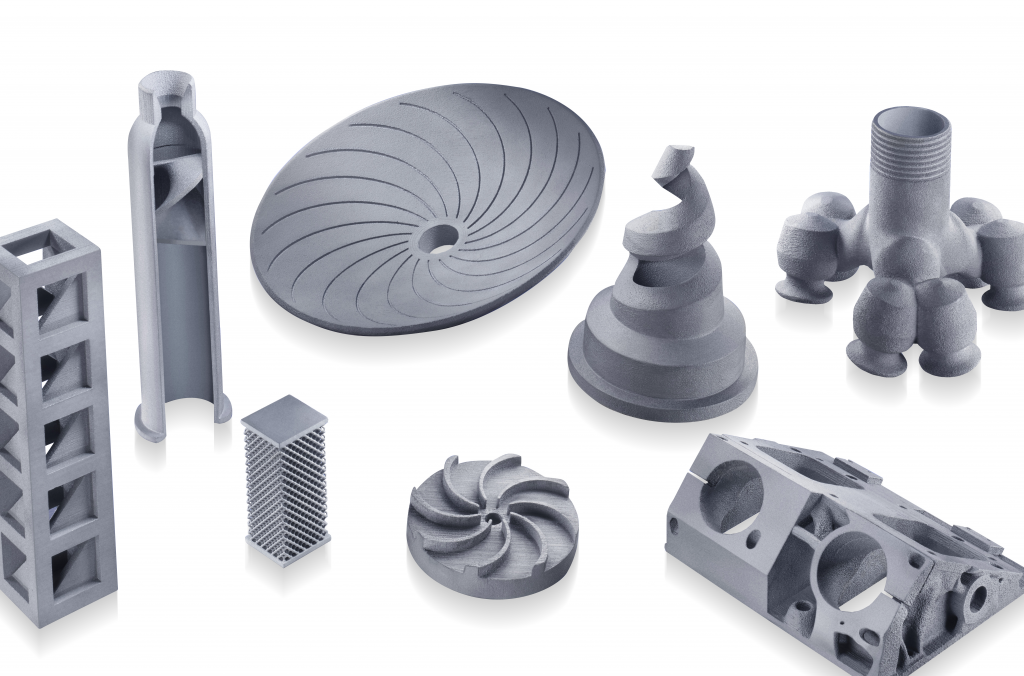

Ceramic specialist CeramTec has added a new ‘ROCAR 3D’ printing powder to its material portfolio. The novel resin reportedly possesses the properties of silicon carbide (SiSiC), making it potentially well-suited to either fabricating prototype parts, or engaging in small production runs within plant-based settings.

According to the company, 3D printing still isn’t commonly-used to fabricate industrial ceramic parts, but the new material could change this by offering faster processing speeds and better value for money than conventional ceramics allow.

Speciality materials manufacturer AGC Chemicals Americas has unveiled a new family of silica gels called SOLESHPHERE. The product range has been built from the ground up to work with SLA, FDM and LPBF systems, and once printed, they reportedly yield parts that display excellent tensile strength and temperature-resistance qualities.

All four of the materials are characterized by a smooth surface, large particle size and low surface area, which helps to lower the viscosity of the final resin and improve its distribution. Similarly, with a purity of over 99%, the silica gels don’t alter the chemical bonds of a resin’s polymer matrices, resulting in printed structures with a high level of stability.

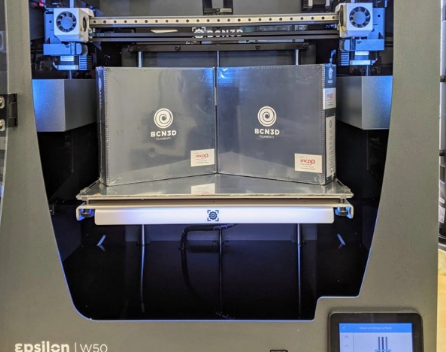

Finally, in terms of material news, Spanish 3D printer manufacturer BCN3D has partnered with chemical firms Mitsubishi Chemical and BASF to launch two new filaments. The first, which is called Tough PLA, combines ABS-like impact resistance with the stiffness normally seen in PLAs, while its printability lends it to functional prototyping applications.

The firm’s second filament is a water-soluble thermoplastic referred to as ‘BVOH,’ which has been specifically optimized for the FDM 3D printing process. According to the company, the material is easy to remove from inside small parts which reduces potential clogging, and its solubility makes it an ideal dissolvable support when printing complex parts.

Additionally, BCN3D’s Epsilon W50 3D printer is currently under review by 3D Printing Industry’s own team of talented test engineers. The machine is being subjected to rigorous testing, including fabricating different parts using the firm’s latest filaments, and readers will be able to get the full lowdown on how it performs via a detailed article in the near future.

ExOne and ROBOZE make business moves

Binder jetting 3D printer manufacturer ExOne has announced a $90 million public share offering, but at a value of $54 per share, 16% lower than the $64.50 it closed at on Tuesday. The move closely follows the launch of its new Designlab system, while the firm intends to use the additional funding both as working capital, and to continue its expansion.

In other business news, Italian and US-based 3D printer manufacturer ROBOZE has introduced a subscription plan for its ARGO 500 systems. The all-inclusive fee entitles users to not just to access the machine, but a range of proprietary polymers and composites, as well as the company’s suite of support services and cloud-based software updates.

“To make our vision a reality, we must take a comprehensive approach,” explained ROBOZE Founder and CEO, Alessio Lorusso. “The most important element is to help customers drive their business through expanding their knowledge in materials science and CAD design for additive manufacturing. We don’t just provide a machine, we help our partners and customers master the technology.”

Distribution deals from JuggerBot 3D, GoEngineer and more

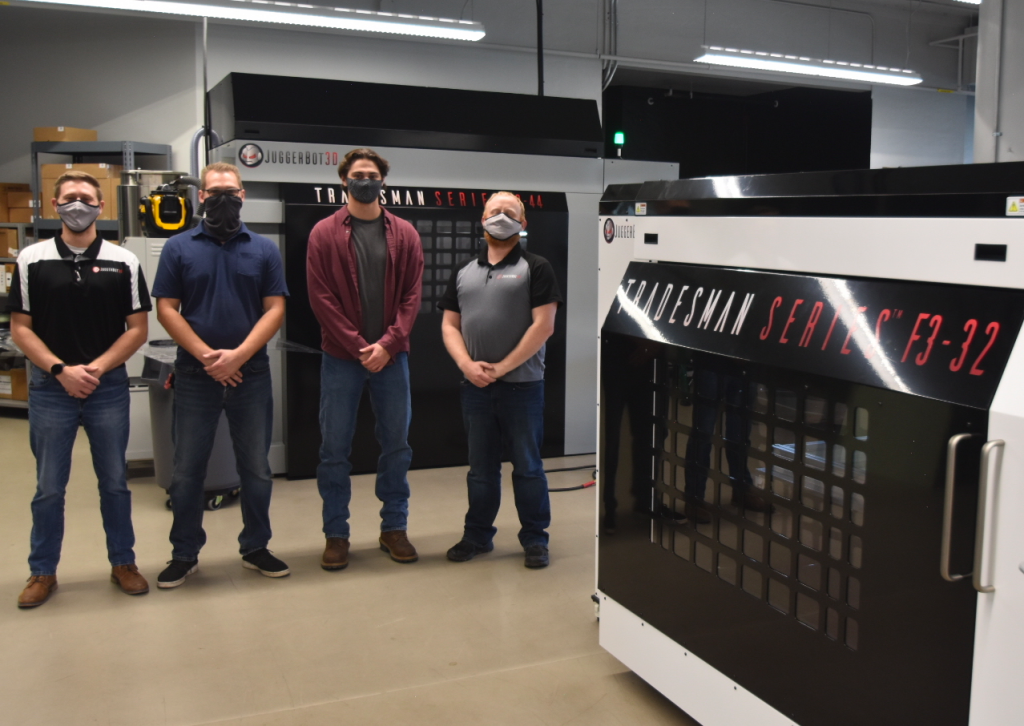

In one of several distribution agreements this week, 3D printing, engineering and consulting firm JuggerBot 3D has announced that it has established its own reseller network. Machine tool distributor JBM Technologies will now have exclusive rights to sell JuggerBot’s systems in Pennsylvania, while its partner Tipton Technologies will do the same in Northern Ohio.

As part of the deal, JBM and Titpton have also agreed to provide JuggerBot’s clients with support after installation, including training, developing custom applications and conducting preventative maintenance, as well as free technical expertise.

“JuggerBot 3D is thrilled to partner with the JBM Group, having demonstrated a commitment to the success of their customers in Pennsylvania and Ohio for decades,” said Dan Fernback, VP and Co-Founder of JuggerBot. “Our Tradesman Series fits well with JBM’s current line of equipment, and provides their customers with a wider selection of tools to win.”

Similarly, Metal 3D printer manufacturing startup Xact Metal has entered into an exclusive sales and service partnership with 3D software specialist GoEngineer. The deal, which covers the entire West side of the United States, will see GoEngineer market Xact Metal’s line of low-cost metal 3D printers alongside its existing range.

“We are pleased to announce our partnership with Xact Metal to offer high-quality, metal 3D printing in a sustainable and affordable way,” said Ken Coburn, Owner of GoEngineer. “Xact Metal’s combination of powder-bed fusion and innovative, advanced technologies will allow a variety of companies to thrive in AM and differentiate themselves in their marketplace.”

Elsewhere, Texas-based resin supplier Adaptive3D has announced that it has shipped its first Carima DM400A DLP 3D printer in North America. The top-down VAT machine was delivered to an unnamed healthcare client, which intends to utilize it to process the firm’s proprietary Elastic and Soft ToughRubber materials into elastomeric medical parts.

As opposed to standard DLP systems, the Adaptive3D’s machine features two 2K ultra HD light engines that face downward toward the print area. According to the company, this setup not only allows parts to overcome any separation forces during printing, but provides users with greater scalability and access to higher volume production runs.

“We believe that top-down DLP is the optimal platform for processing this class of photopolymers for larger parts or larger batch sizes, higher throughput and lower cost,” said Adaptive3D’s VP of Sales & Marketing Kial Gramley. “The Carima DM400A delivers part and batch sizes more than ten times the highest throughput that the bottom-up DLP competition has to offer.”

Stratasys has also revealed distribution news, as the 3D printing service bureau InterPRO Additive Manufacturing has acquired three of its Origin One machines. The purchase trebles InterPRO’s 3D printing capacity, and using its new systems, the company anticipates that it will be able to fabricate 40,000 parts during 2021, twenty times more than in 2020.

“Adding three more machines was an easy decision,” said Dan Straka, President of InterPRO. “Our clients are seeing real success from our service offering. Origin parts are a combination of cosmetically appealing and advanced material properties that you don’t typically see in 3D printed thermoset plastics.”

Applications: cycling, sailing and 3D printed vegetables

Finishing this week with 3D printing applications, global engineering firm Renishaw has issued a statement expressing its “delight” that the INEOS UK sailing team have made it to this Saturday’s PRADA America’s Cup World Series Final. The company has been acting as a ‘precision measurement and AM partner’ to the crew, contributing its expertise to the build of the team’s 75-foot ‘BRITANNIA’ racing boat.

Using 3D printing, Renishaw says it has been able to optimize several structural components onboard the vessel, creating lightweight parts that were robust enough to survive trial by sea. The British firm also supplied equipment and advice in the fields of position sensing, manufacturing process control and Raman spectroscopy throughout the event.

“The Renishaw controller was really put through its paces when issues arose with the team’s cunningham (one of the boat’s directional settings),” said Finlay Evans, Technical Leader for Renishaw’s Encoder Products Division. “Bleddyn Mon’s hard work with the bespoke controller, that we helped to design and manufacture, really contributed to the team’s hard-fought victory to qualify for the PRADA Cup final.”

Turning from sailing to cycling, Purmundus Award-winner Huhn Cycles has been commissioned by a former 4X racer to develop a new 3D printed ‘Hardtail’ bicycle called ‘La Fleche’ (or The Arrow). The revised design is being built to accommodate more hardcore offroad biking, thus the ex-rider has requested highly-precise angles for each joint.

While most of the connections on Huhn’s previous bike were 3D printed, in this case only the seatube junction and headtube will be fabricated, with the rest fillet brazed. Despite this, the firm’s founder Ralf Holleis maintains that these areas are vital to the design’s overall strength, and remain important to its appearance.

Lastly, in an odd foliage-themed twist, researchers at Nanyang Technological University, Singapore University of Technology and Design (SUTD) and Khoo Teck Puat Hospital (KTPH) have developed a new method of creating “food inks” from vegetables.

While similar inks have been 3D printed into pureed food for dysphagia patients in the past, they’ve often been a different taste, texture and aroma to the real thing. To combat this, the team combined fresh and frozen veg such as garden peas and carrots, with the aim of creating more stable and appetizing meals.

“Our method of 3D printing fresh vegetables can be used easily in hospitals, nursing homes and day care centres for the ageing population,” concluded Yi Zhang, the principal investigator from NTU. “Our research is also another step forward in digital gastronomy, where we can cater to specific requirements prescribed by dieticians.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of Huhn Cycle’s new 3D printed bicycle. Photo via pinkbike.com.