Carpenter Technology, a metal alloy manufacturer based in Pennsylvania, has established a new additive manufacturing facility known as the Emerging Technology Center (ETC), in Athens, Alabama.

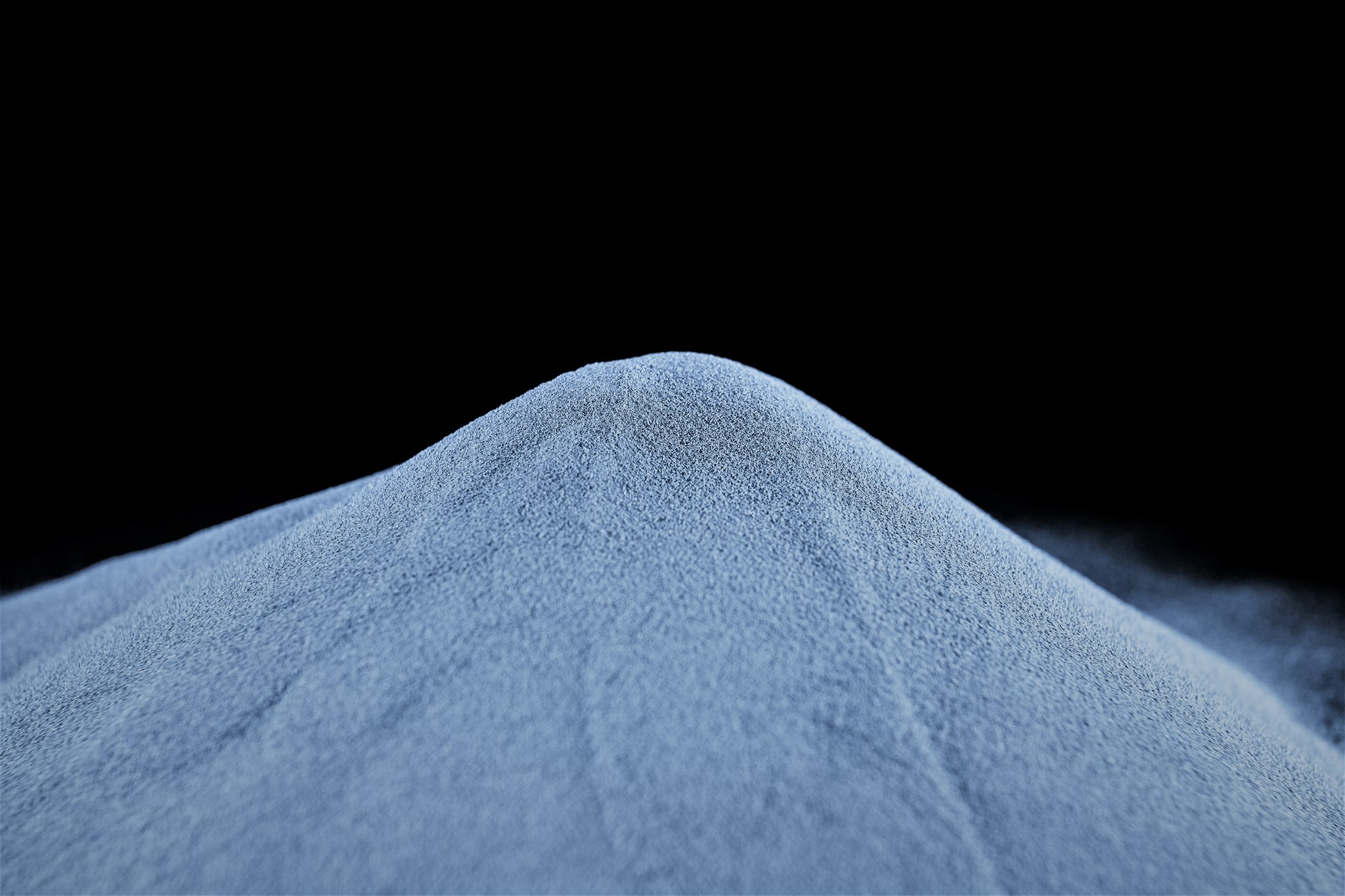

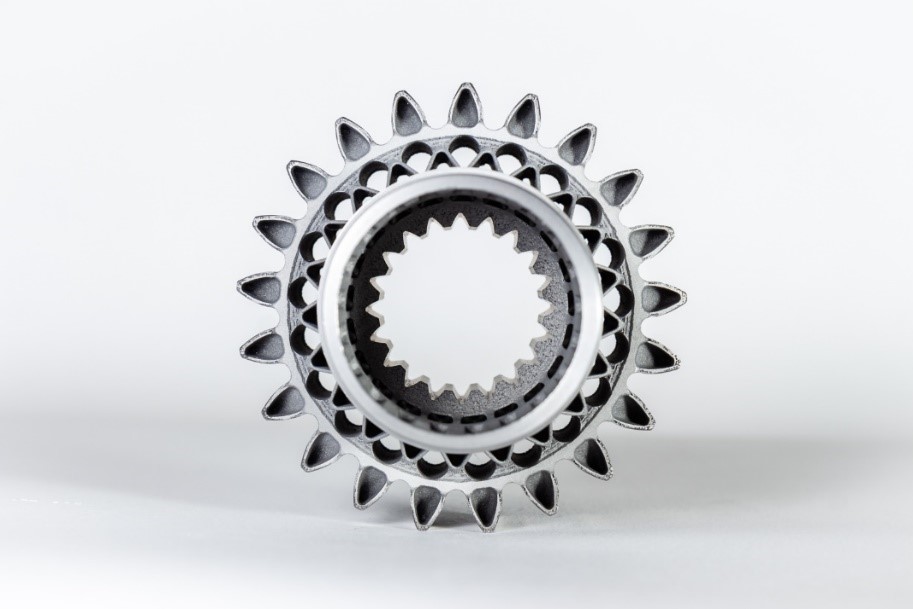

The 500,000-square-foot center will provide the capability to atomize specialty alloys into metal powder which can be used within additive manufacturing. Metal 3D printed parts created at the ETC can then be qualified for use industrial applications, including aerospace, transportation, and oil, gas & energy.

“Our Emerging Technology Center is a critical component of Carpenter Technology’s future growth and development, and is aligned with our business strategy of evolving to an end-to-end solutions provider and influential leader in the AM area,” said Tony Thene, CEO of Carpenter Technology.

“We will also use it as a base to launch future investments as we expand our soft magnetics technology platform, scale-up additional powder operations and demonstrate a number of next-generation materials we have under development today.”

The Emerging Technology Center

Investing an estimated $40 million, Carpenter Technology’s ETC is expected to accelerate North America’s advanced technology position. The company has invested an overall amount of $600 million in its Alabama operations and expects the ETC to create around 60 jobs over the next five years.

It is designed to maintain full traceability and provide analytical insights throughout the additive manufacturing process via a digital thread. The equipment included within the ETC currently comprises of a cooling Hot Isostatic Press (HIP) system, as well as vacuum heat treating processes to optimize the material properties of high-value specialty alloy components.

“We have chosen to continue to invest in North Alabama because it offers three important advantages—a high-quality, tech-oriented workforce, a clear connection with the aerospace industry and a close working partnership with state and local

government officials” added Thene.

Accelerating additive manufacturing materials

Carpenter Technology has deepened its involvement within the 3D printing industry. Earlier this year, Carpenter Technology partnered with Belgium-headquartered aircraft component manufacturer BMT Aerospace to 3D print components for the aerospace industry. Moreover, the company also recently formed a 3D printer materials business Carpenter Additive, which controls all of it’s specially made powders for metal additive manufacturing, as well as R&D and production services.

“Carpenter Technology’s new Emerging Technology Center will power game-changing advances in the company’s development of sophisticated new additive manufacturing technologies,” said Greg Canfield, secretary of the Alabama Department of Commerce.

“With the ETC, Carpenter Technology is bringing new capabilities to Alabama’s manufacturing sector, and I can’t wait to see how the work conducted there helps to shape the future for this great company.”

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the 3D printing industry? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows the Emerging Technology Center (ETC), in Athens, Alabama. Photo via Carpenter Technology.