Carbon Source, a subsidiary of Washington-based resource reclamation firm CarbonMeta Technologies, has announced a Plastic Upcycling Partner Program for 3D printing service providers and makerspaces.

The program will give 3D printing filament purchase discounts to partners who upcycle their waste plastics through Carbon Source, as the company attempts to reduce the amount of waste plastic disposed of in landfills.

The firm has also unveiled its Upcycling Classroom Grant Program which aims to encourage students to come up with new ways of upcycling waste plastics within their local communities.

“This Plastic Upcycling Partner Program provides incentives that encourage makerspaces and 3D printer services to upcycle their waste plastics and better steward thermoplastic materials,” said Lloyd Spencer, Chairman and CEO of CarbonMeta Technologies, and Carbon Source President.

“This program will improve traceability of Carbon Source’s plastic production with its partners, which is the first step toward certifying and tracking waste plastics in a manner that is similar to tracking carbon credits.”

Recycling 3D printing filaments

Carbon Source upcycles plastic waste into 3D printing filament in order to drive greater circularity within the additive manufacturing sector. The company contributes a portion of the purchases for its recycled filaments to fund recycled plastic project grants awarded to clubs and schools each quarter.

Market Data Forecast estimates the global 3D printing plastics market was worth $698 million in 2021 and is predicted to reach $1.96 billion by 2026. However, according to Carbon Source, only a small fraction of filaments are currently manufactured from recycled plastics. As such, the projected growth of the market means proper waste management strategies need to be developed.

The company currently markets recycled 3D printer filaments made from HIPS and PETG thermoplastics. Going forwards, the firm plans to offer filaments that are made up of at least 50 percent used PET and PLA.

Through its Plastic Upcycling Partner Program, Carbon Source will offer discounts of up to 15 percent on 3D printer filaments purchased through its online store. Program partners based in western Washington will also be eligible for free one-day delivery.

The first partners of the program will be Seattle-based makerspace Seattle Makers and Washington-based SnoCo Makerspace.

Upcycling Classroom Grant Program

In addition to launching its Plastic Upcycling Partner Program, Carbon Source has announced a new Upcycling Classroom Grant Program aimed at schools and youth organizations. The grant seeks to encourage students to come up with new upcycling methods and technologies to help reduce the amount of waste plastic that finds its way into our waterways and landfill sites.

Those applying for a grant should address environmental problems in their local community through some form of upcycling waste plastic. Grant awards will be made at the end of each quarter and can range from between $500 to $2,500 per application.

To be eligible, schools and organizations must be located within the US or its territories, including Puerto Rico, Guam, and American Samoa.

Repurposing waste for 3D printing

The disposal and repurposing of waste are receiving growing attention within a whole spectrum of manufacturing industries, with 3D printing being no exception. Plastic waste, in particular, has become a big focus for numerous companies within the sector that are seeking to achieve greater circularity within their production processes.

For instance, industrial 3D printer manufacturer Roboze recently launched its circular economy program for waste material that allows customers to return their waste material and parts at the end of their lifecycle to be processed into recycled 3D printing materials. The project is seeking to reduce the firm’s environmental impact while also offering its customers recycled materials at a lower price point.

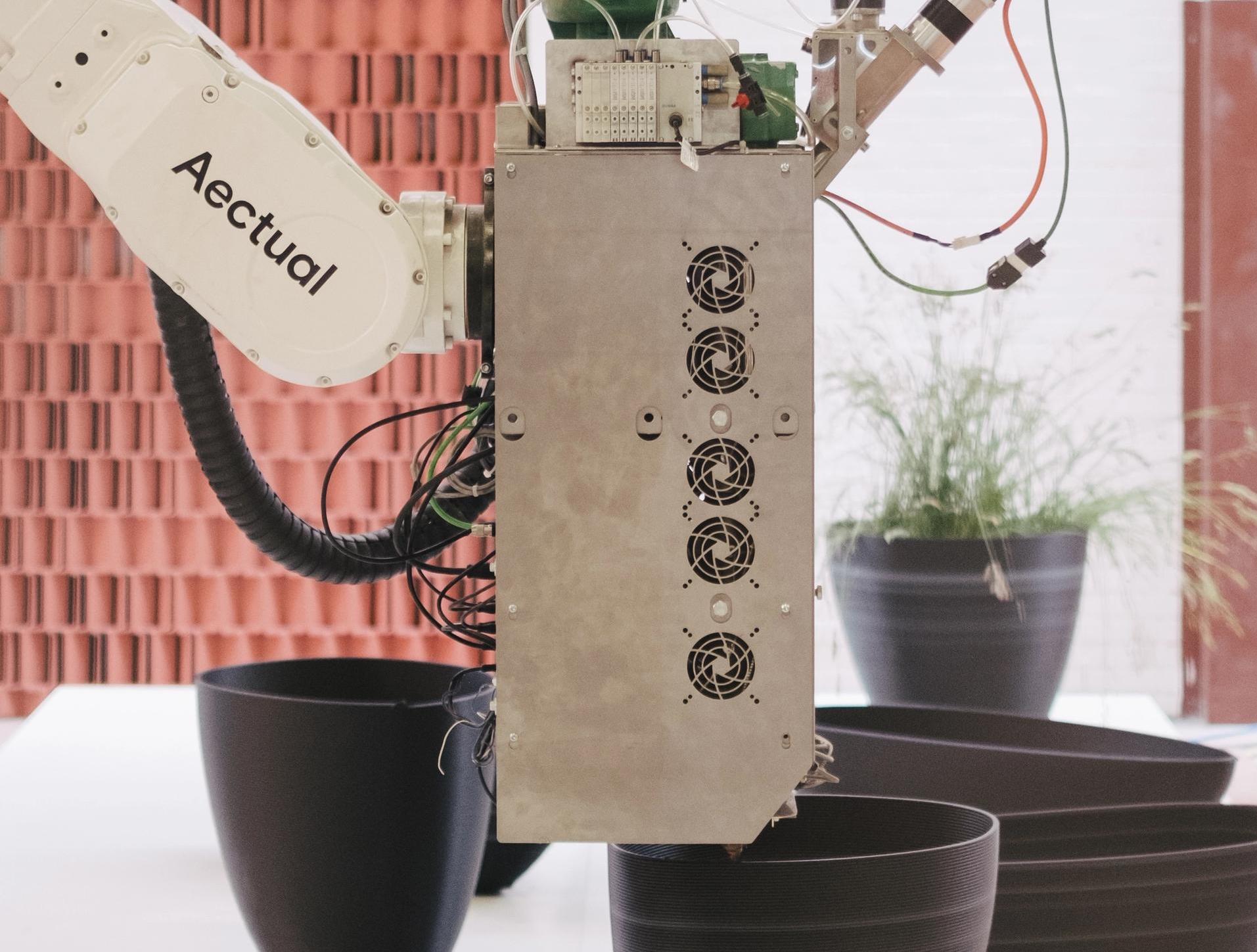

Elsewhere, several projects have demonstrated how plastic waste can be repurposed for a variety of different uses. Dutch 3D printing service Royal3D used plastic PET waste to construct a 3D printed modular and flexible workspace pavilion for the Rotterdam Makers District, while fellow Dutch architecture firm Aectual transformed beach plastic into a unique range of 3D printed mussel-shaped plant holders.

Meanwhile, Austrian design studio EOOS has recycled polymeric waste into a novel electric tricycle via 3D printing, which it believes could help reduce carbon emissions around the world once deployed.

Progress has also occurred within the research sphere regarding waste plastic, with the Chinese University of Hong Kong having developed a 3D printing material made up of plant leaves and plastic waste that can be dissolved almost entirely on-demand. Also in the last year, researchers at Loughborough University have managed to turn plastic waste into low-cost 3D printed agricultural tools for African farmers, and engineers from McGill University and Ryerson University have turned wind turbine waste into a robust new PLA 3D printing material.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Carbon Source’s Closed Loop Plastics Party Pink U-HIPS made entirely from waste plastic cups and lids. Image via Carbon Source.