High-performance backpack manufacturer Osprey has leveraged Carbon’s DLS 3D printing technology to create a 3D printed lumbar for its new pack series, Osprey UNLTD, that delivers superior mechanical properties while also reducing manufacturing waste.

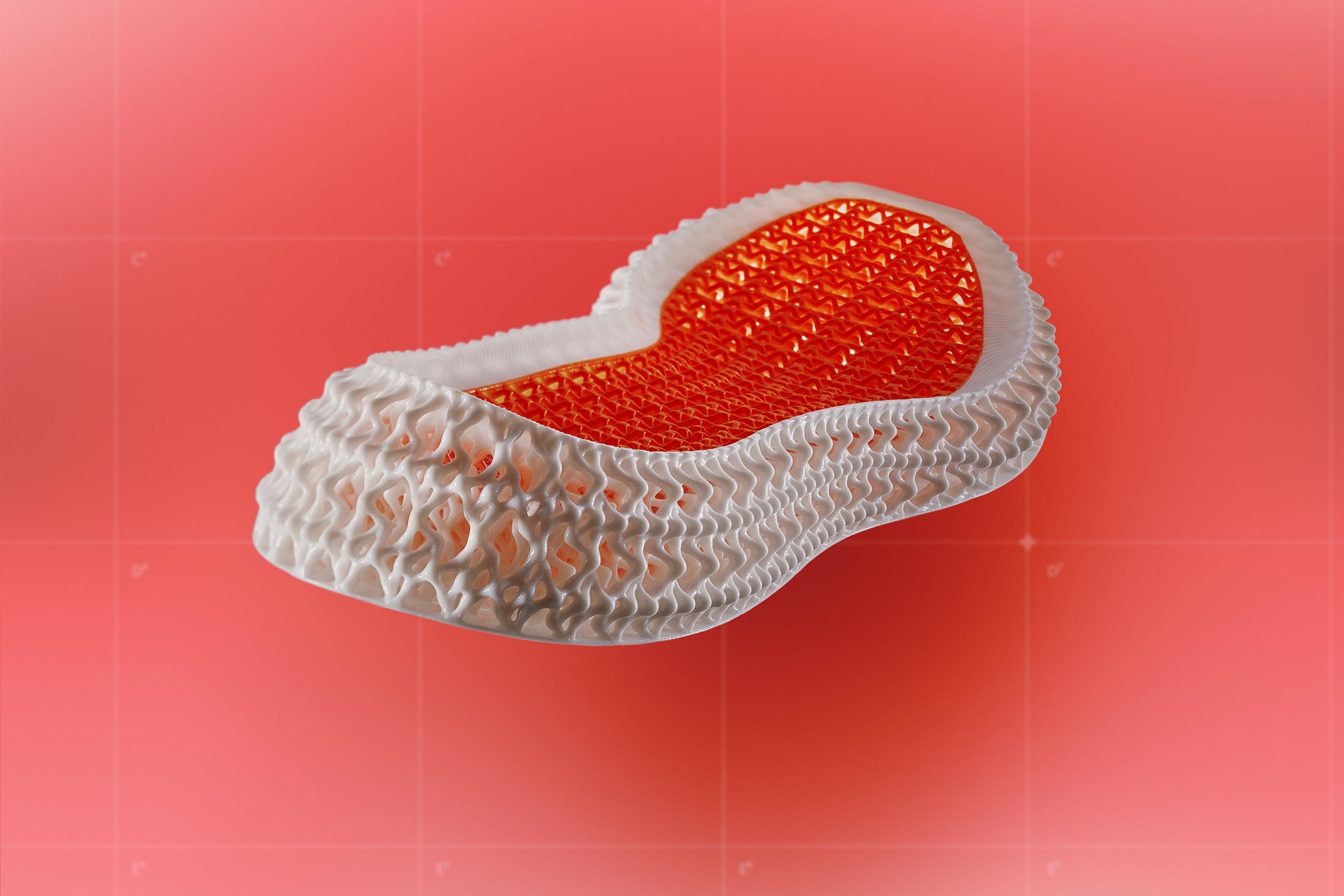

The 3D printed Fitscape Lumbar is the result of a two-year design journey by the firm, and is engineered to deliver superior ventilation, fine-tuned cushion support, and an anti-slip surface grip to keep loads in place.

According to Osprey, the use of DLS 3D printing has opened up the use of materials previously untapped by the pack industry, and improves upon the development timelines of traditional manufacturing methods.

“Osprey UNLTD is the manifestation of Osprey’s approach to innovation,” said Rob BonDurant, VP Marketing at Osprey Packs. “In developing Osprey UNLTD, we removed the shackles of commercialization and production schedules to move beyond traditional manufacturing technologies ushering in a new era of backpack design and the ultimate backpacking experience.”

Carbon’s DLS technology

Carbon’s DLS 3D printing technology is an SLA-based process that uses digital light projections in tandem with oxygen-permeable optics to cure photopolymer resins into 3D parts. The firm’s systems use materials embedded with heat-activated programmable chemistries to enable the fabrication of parts with engineering-grade mechanical properties and high-resolution features.

Carbon’s flagship product line is the M Series, made up of its M1, M2 and most recently launched M3 and M3 Max 3D printers. The latest additions offer improved print speeds, larger build volumes, and higher-quality parts over their predecessors, and are suited to applications ranging from automotive and life sciences to dental and consumer goods.

For instance, the company’s DLS technology has been leveraged by German sportswear giant Adidas to create its 3D printed 4D midsole, the 4DFWD, the latest version of which was launched to the public in August last year. DLS 3D printing has also been adopted by cycling equipment manufacturer fizik to create its Adaptive 3D printed bike saddle, and by bicycle manufacturer Specialized for its own 3D printed bike seat.

The company is continually looking at new opportunities to expand its materials palette, and for new applications within fields observing increasing adoption of additive manufacturing such as medical.

3D printing backpacks with Osprey

Osprey’s 3D printed Fitscape Lumbar is the latest consumer goods application of Carbon’s DLS technology, with the firm claiming to be the first backpack manufacturer to harness DLS technology to enhance its products.

A lumber pack is designed to distribute all its weight directly onto the wearer’s hips and skeletal structure in order to alleviate stress on their back. Over the past two years, Osprey has been designing an optimized lunar pad for its new UNLTD series, and key to this has been the use of Carbon’s DLS technology.

According to the firm, 3D printing the Fitscape Lumbar has improved the pad’s ventilation and helped to fine-tune its cushion support, while also delivering an anti-slip surface to better keep loads firmly in place. The lumbar is formed from a polycarbonate vacuum-formed framesheet which features thermo-formed air channel ribs on the backpanel to optimize support, fit and ventilation.

Adopting additive manufacturing has also helped Osprey to reduce the waste within the manufacturing process and expedite the time-to-market for its UNLTD series.

“Traditional manufacturing methods teach us that in order to push the boundaries of innovation, product development timelines need to be extended,” said Phil DeSimone, Carbon Co-founder and Chief Product and Business Development Officer. “The development of Osprey UNLTD proved the exact opposite.

“The entire process using Carbon DLS took about one year with only six months for us to iterate on the design, enabling Osprey to take this innovative product to market faster.”

The UNLTD backpack series features a number of innovative upgrades alongside the 3D printed Fitscape Lumbar, such as an Autolift system that helps to comfortably distribute the pack’s load and a Fit-on-the-Fly adjustment to the pack’s shoulder strap. The backpack series also features state-of-the-art lightweight and durable fabrics, a deluxe nylon rain cover, and a custom Airporter Cover with lockable zippers to secure the pack during transit.

The Osprey UNLTD is available in four styles, namely the UNLTD Airscape 68 and Osprey UNLTD Anti-Gravity 64, for which both men’s and women’s models are offered.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Osprey’s 3D printed Fitscape Lumbar. Image via Carbon.