A research team led by Boston University has used 3D printing technology to develop a miniature replica of a human heart – and it beats like the real thing.

Named the cardiac miniaturized Precision-enabled Unidirectional Microfluidic Pump, aka the miniPUMP, the device was created using a combination of stem cell-derived human heart cells and micro-scale 3D printed acrylic parts. Designed to behave like a real heart chamber, the miniPUMP doesn’t rely on any external sources of power, instead beating by itself thanks to its live tissue.

The researchers believe their heart chamber replica could serve as a testbed to study how the organ works in the human body. It can be used to track how the heart grows in an embryo, how heart tissue is affected by diseases, and how effective new medications are in treating said diseases, all without the need for human testing.

“We can study disease progression in a way that hasn’t been possible before,” says Alice White, a Boston University College of Engineering professor. “We chose to work on heart tissue because of its particularly complicated mechanics, but we showed that, when you take nanotechnology and marry it with tissue engineering, there’s potential for replicating this for multiple organs.”

The challenge of studying the heart

According to the Centers for Disease Control and Prevention, heart disease is the leading cause of death for both men and women in the US, with around 659,000 mortalities every year. That’s one in four deaths. As such, there’s an urgent need to study the vital organ.

However, due to its inaccessible location in the human body, the heart is a tricky thing to study as it can’t just be removed, examined, and replaced on a whim. To address this, researchers have tried several alternative approaches: they’ve manually pumped blood through cadaver hearts and they’ve spring-loaded lab-grown heart tissues to make them expand and contract. Unfortunately, we’re yet to find a suitable lifelike proxy as reanimated hearts can’t beat indefinitely and springs don’t contract like real muscle fibers.

With innovations like the miniPUMP, researchers could eventually mimic and study diseases such as hypertension and valve disease in a more accurate manner. The device is also expected to streamline the drug development process for upcoming medicines, enabling lab-based testing in lieu of costly and tedious human trials.

How was the miniPUMP developed?

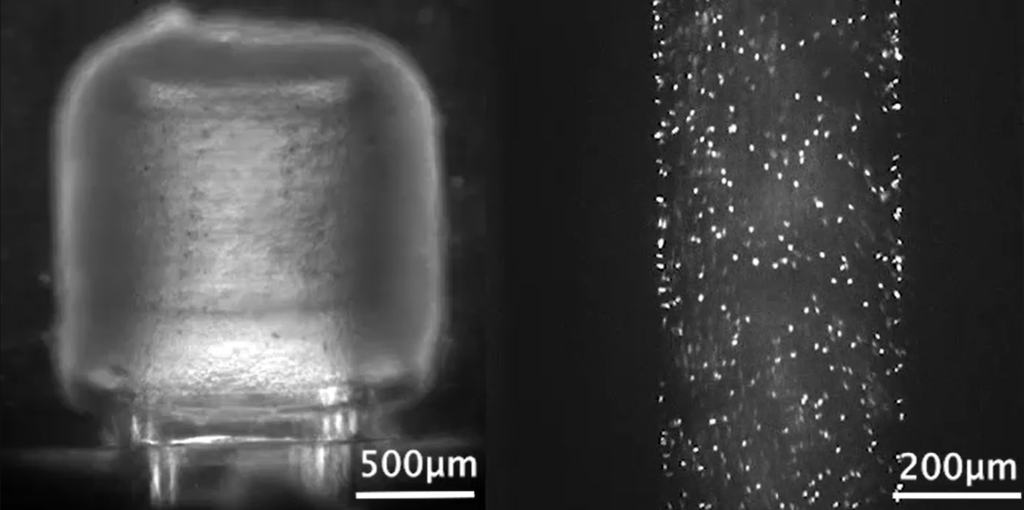

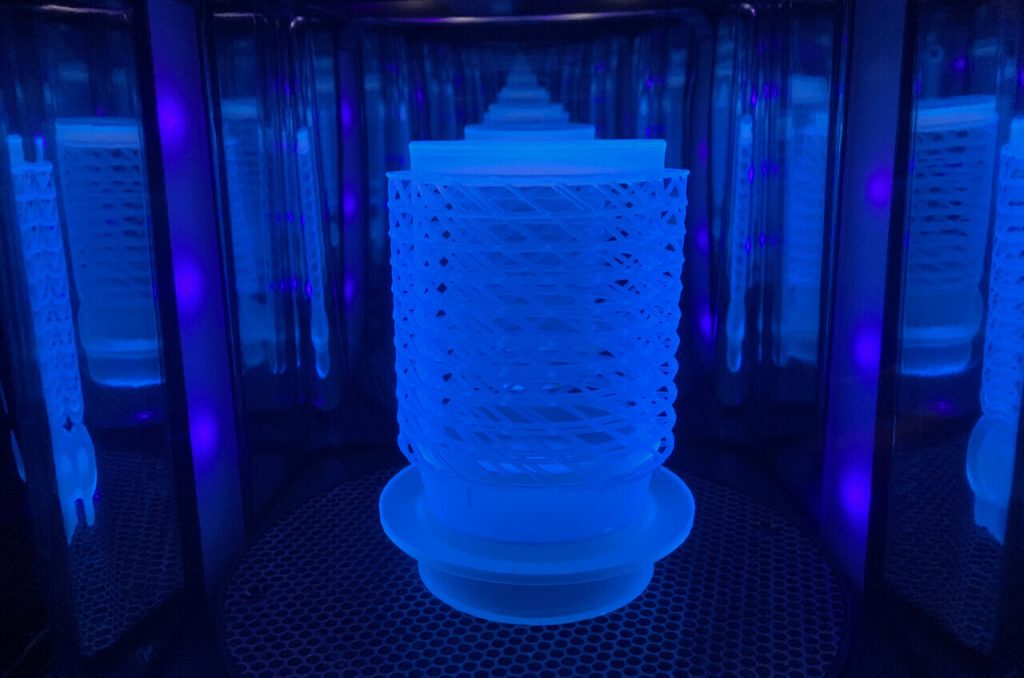

The miniPUMP measures just three square centimeters and features an acrylic scaffold 3D printed using two-photon direct laser writing, a very precise form of micro-SLA. The tiny acrylic valves within open and close to control the flow of fluid, while the miniature tubes serve as arteries and veins. To make the device beat, the researchers also integrated heart muscle cells called cardiomyocytes, which were differentiated from pluripotent stem cells.

The decision to make the miniPUMP so small was a deliberate one, as the 3D printed acrylic scaffolds had to be strong enough to support the structure but thin enough to bend and move with the contracting heart tissue.

“The structural elements are so fine that things that would ordinarily be stiff are flexible,” adds White. “By analogy, think about optical fiber: a glass window is very stiff, but you can wrap a glass optical fiber around your finger. Acrylic can be very stiff, but at the scale involved in the miniPUMP, the acrylic scaffold is able to be compressed by the beating cardiomyocytes.”

As far as next steps go, the miniPUMP research team aims to refine the technology and find ways of manufacturing it reliably. The work can also eventually be applied to implantable patches that may fix defects in the heart, as well as other organs such as livers.

The project is being conducted as part of CELL-MET, a joint National Science Foundation Engineering Research Center in Cellular Metamaterials led by Boston University. The center’s ultimate goal is to create devices capable of regenerating diseased human heart tissue.

The 3D printing of human heart replicas and models is something we’ve seen before. Just last month, researchers from the Technical University of Munich (TUM) and the University of Western Australia developed 3D printed artificial heart valves made from a patient’s own cells that grow as the individual ages. The approach hopes to overcome the drawbacks of conventional prosthetic heart valves, which only last a limited number of years and therefore require multiple replacement surgeries.

Elsewhere, researchers from the Chinese Academy of Sciences (CAS) recently converted a six-axis robotic arm into a 3D bioprinter and used it to fabricate a complex-shaped blood vessel scaffold. The 3D printed vascularized heart tissue remained alive and beating for six months, and could demonstrate a feasible method of bioprinting functional tissues and organs in the future.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

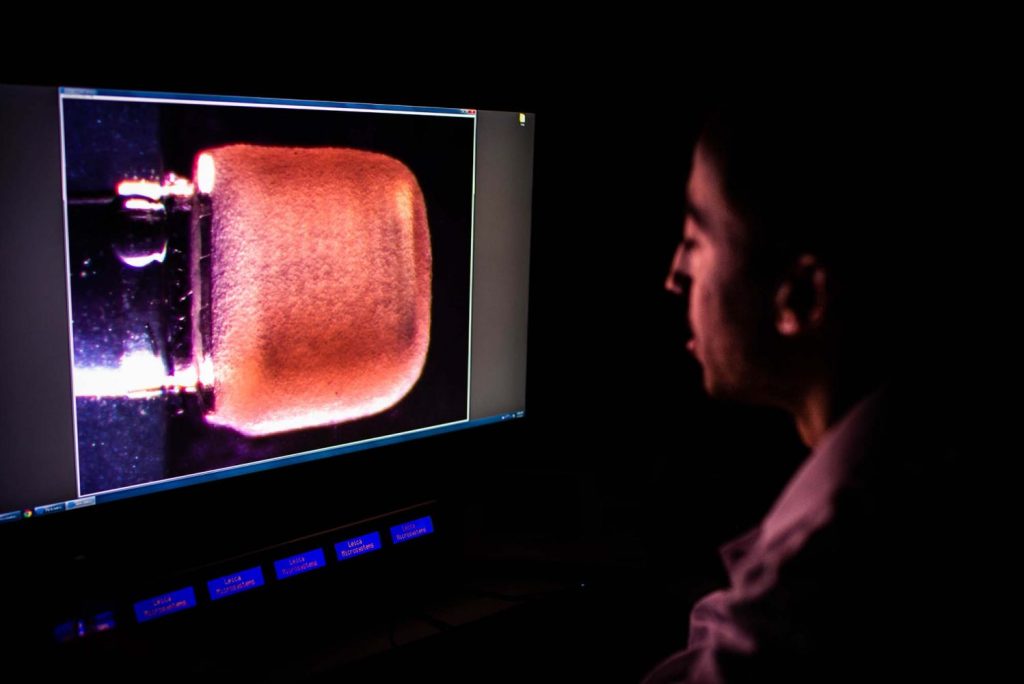

Featured image shows a side view image of the miniPUMP being taken in the lab. Photo via Jackie Ricciardi.