US aerospace manufacturer Boom Supersonic has unveiled a new engine that’s set to enable its upcoming Overture airliner to hit speeds of up to 1,300 mph.

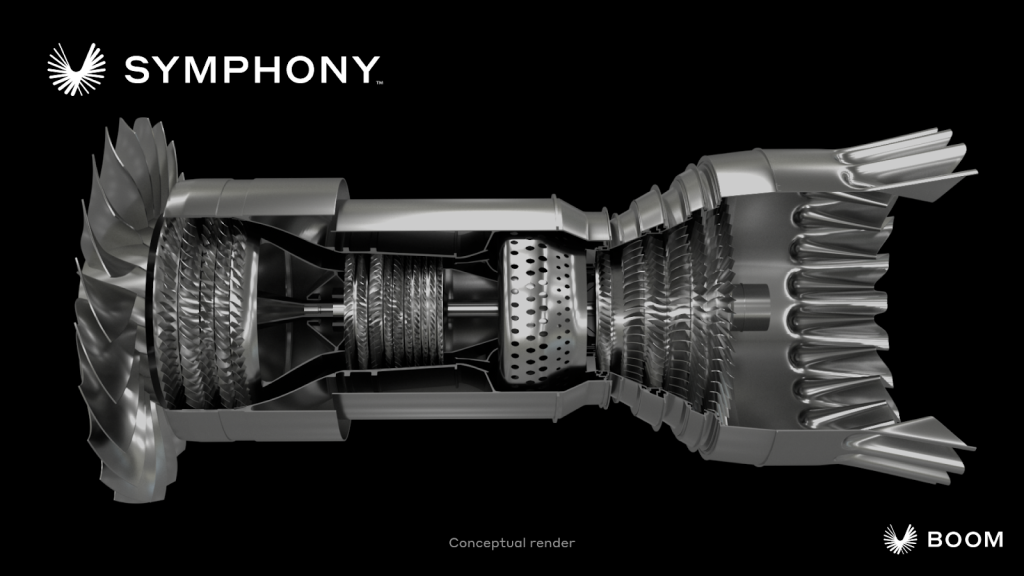

Boom Supersonic’s Symphony propulsion system will largely feature the same basic architecture as the engines of other commercial aircraft, only it’ll also be fitted with sustainability and cost-optimizing axisymmetric supersonic intakes, variable-geometry low-noise exhaust nozzles, and passively-cooled high-pressure turbines.

In addition, to help bring the Overture’s design from the drawing board into reality, the firm has enlisted the help of GE Additive, which will not only offer advice around the build, but seek to identify opportunities for 3D printing in the process.

“We are excited to support Overture and Symphony,” said Chris Schuppe, General Manager of Engineering and Technology at GE Additive. “GE Additive will bring industry-leading capabilities to Symphony, providing additive manufacturing design consulting and technology, while looking for additional areas to potentially collaborate.”

Boom’s supersonic flight plans

During the last eight years, Boom Supersonic has set out to drastically reduce the time it takes to make long-distance journeys, by developing a high-speed passenger jet. Known as the Overture, the firm’s Mach 1.7-speed aircraft is being built to fly 65-80 people over distances of more than 4800 miles, at a 20% faster pace over land, and twice as quickly over water.

In order to prove the viability of its Overture design, the company is first producing a demonstrator craft called the XB-1. Already, additive manufacturing has become a key enabler of the aircraft’s manufacturing process, with Boom Supersonic and Stratasys partnering to develop some of its end-use parts as long ago as 2017.

More recently, it was revealed that Velo3D 3D printed 21 parts of the XB-1, including vanes, ducts, and louvres, designed to channel air at high temperatures. Fabricated largely using a Sapphire 3D printer, these builds not only showed how Velo3D’s technology enables the creation of less brittle, crack-prone titanium components, but reflect the importance of 3D printing in Boom Supersonic’s future plans.

Reaching out to realize a Symphony

According to Boom Supersonic, the Symphony will be a medium-bypass turbofan engine with the same basic layout that powers all modern commercial aircraft. However, the new propulsion system is also set to feature unique design innovations that improve both its supersonic flight performance and efficiency, while allowing it to meet Chapter 14 noise restrictions and making it carbon net-zero.

In terms of performance, the Symphony is expected to deliver a 25% increase in ‘time on wing’ and significantly lower engine maintenance costs, in addition to helping lower airplane operating costs by 10% for its airline customers. Practically, it’s said the engine will be able to achieve this thanks to its 100% sustainable fuel, quietly-operating single-stage fan and passively-cooled high-pressure turbine.

To aid its engine production efforts, the company is partnering with industry leaders, in the form of Florida Turbine Technologies (FTT), StandardAero and GE Additive. While the former are set to assist Boom Supersonic’s Symphony design and maintenance plans, the latter will be consulted on how best to use 3D printing within part consolidation as well as lightweighting, and reducing assembly costs.

Given its longstanding expertise in aerospace 3D printing, GE Additive could prove to be a key partner on the project. In fact, the GE-3D printed fuel nozzle tip is one of most successful use cases for the technology in the sector. As revealed in 3D Printing Industry’s tour of GE’s Cincinnati facilities, it has manufactured over 140,000 of the components, which are said to be 15% more fuel efficient than standard.

“Boom’s strategy with Symphony is quite innovative,” Boom Senior Advisor, former Rolls-Royce CTO, and Chair of Singapore Aerospace Programme Ric Parker added. “Their approach makes it compelling for top-tier suppliers to have the opportunity to contribute their expertise and capabilities to this exciting, breakthrough supersonic engine program.”

3D printing’s part consolidating, lightweighting and heat resilience-reinforcing capabilities, mean that it unsurprisingly continues to find high-speed aerospace applications. Earlier this month, it was revealed that China is using 3D printing in the build of its fighter jets. While the models of these planes weren’t disclosed, their manufacturer is known to be behind the Shenyang FC-31 stealth fighter.

Elsewhere, in a more civilian-oriented use case, Hermeus is deploying the technology in the production of its partially-3D printed Chimera jet engine. Set to power the firm’s upcoming supersonic Quarterhorse aircraft, the propulsion system recently completed testing, in which it proved capable of repeatedly transitioning from a turbojet mode designed for launch, into a high-Mach speed ramjet mode.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a render of the Boom Supersonic Overture airliner. Image via Boom Supersonic.