Microscale 3D printer manufacturer Boston Micro Fabrication (BMF) has achieved 30% YoY sales growth at the close of its FY 2023 reporting period.

The company has called 2023 a “landmark year,” which has seen it enter the dental market, expand research at the San Diego Research Institute, and raise $24 million in series D funding.

According to BMF, its sales growth has been driven in large part by high precision 3D printing demands across medtech, electronics and life sciences applications

The company has also focused on identifying and exploring new, unique applications for its high-precision micro-resolution 3D printing technology, Projection Micro Stereolithography (PμSL).

Last year, in an interview with 3D Printing Industry, BMF CEO John Kawola provided additional insights into BMF’s micro-3D printing technology and business model.

The company’s DLP-based 3D printing process leverages light, customizable optics, a high-quality movement platform, and controlled processing technology to 3D print parts at the 2µm scale. New materials such as BMF MED and Formula1μ from Mechnano have reportedly helped to propel PμSL technology into new industries.

In response to the company’s FY 2023 financial results, Kawola commented, “Amid a challenging economic environment on both a global stage and for the 3D printing industry, we are very proud of the progress made over the last year to help our customers push the boundaries on what is possible with our technology.”

“And while a lot of this success is due to strong execution from our team, much of it is based on our product-market focus and the fact that we are building a high value, differentiated business,” added Kawola.

Series D funding triggers growth

August 2023 saw BMF raise $24 million in a series D funding round led by Chinese finance service corporation Guotai Junan Securities. This followed a successful $42 million series C financing round in 2022.

At the time, BMF Co-Founder and CEO Xiaoning He stated that the Series D funding will be leveraged to “continue to empower and incubate products in related application fields and collaborate extensively with our partners to advance micro-scale additive manufacturing.”

Following this investment, BMF’s team has now grown to over 200 people, with the company serving more than 1,800 companies worldwide.

How is this financing being utilized to expedite growth? According to Kawola, BMF’s long term growth strategy revolves around application development and differentiation. It targets markets that require precision, and capitalizes on miniaturization trends, and ceramic 3D printing.

Ultimately, Kawola claims that one of BMF’s key strengths is its distinctiveness in the 3D printing industry. The company operates in a high-growth area, seeing minimal competition and solid gross margins which result in high profitability.

“I think for companies to survive, they need to be differentiated and offer a product that they can charge enough money for that they can build a business around,” Kawola told 3D Printing Industry.

BMF enters dental market

One new market BMF targeted in 2023 was dental, with the launch of UltraThineer, reportedly the “world’s thinnest cosmetic dental veneer.” This new 3D printed dental product is part of BMF’s ongoing strategy to identify and develop high value applications where its micro-3D printing expertise can add value.

Produced using PµSL technology, the 3D printed veneers are designed to be three times thinner than their conventional counterparts. The company’s novel micro-3D printing approach is said to drastically reduce the preparatory steps required for dental practitioners.

The UltraThineer product offering will enter the US market this year. According to BMF, testing and development has been going well, with US Food and Drug Administration (FDA) clearance expected by mid-2024.

“Small parts requiring very high levels of precision are difficult to prototype and manufacture, and we are continuing to address segments of the manufacturing and design market that may not be possible through other methods,” stated Kawola. “3D printing is a powerful tool here, and we’re continuing to uncover new applications for our technology.”

San Diego Research Institute developing 3D printed lab-on-chip

2023 also saw BMF begin research at its San Diego Research Institute. The research center, which opened its doors in September 2022, has been formed to develop and incubate end-product ideas uniquely enabled by BMF’s micro-3D printing technology.

The first initiative being pursued at the center relates to the development of next generation lab-on-chip structures which leverage the advantages of micro-3D printing for the creation of cell and tissue cultures. These efforts are being led by Dr. Chunguang Xia, CTO and CoFounder of BMF, and Dr. Jennifer Sun, director of the San Diego Research Institute.

The lab-on-chip concept isn’t new. However, BMF’s new offering reportedly introduces a vascularized platform for drug discovery and cosmetic testing. The research center seeks to revolutionize the lab-on-chip industry through research and development of new production methods and advanced capabilities.

2023 sees developments in micro-3D printing

Micro-3d printing technology is a growing area within the additive manufacturing industry, with a number of new developments in this space announced last year.

BiologIC Technologies, the UK-based biotechnology company behind the 3D printed ‘lab-on-a-chip’ platform, received funding from Innovate UK as part of the Analysis for Innovators (A4I) grant programme. This financial support is being used to accelerate the development and manufacture of cheaper drugs and vaccines with micro-3D printed chips.

2023 also saw the launch of resin 3D printer manufacturer B9Creations’ ultra precision B9 Elite Micro 3D printer. This system offers ultra-high resolution, accuracy, precision and repeatability.

The micro-3D printer features a native pixel size of 20 microns and micro features like holes of 100 microns, allowing it to produce high-quality micro components at a quarter of the price of more high-end systems. The B9 Elite Micro is compatible with both B9Creations and third party materials, with users also able to employ their own custom resins.

Elsewhere, researchers from Queensland University of Technology conducted a case study to evaluate the use of different resins for 3D printing microfluidic components for cell-based applications.

The researchers used MOIIN High Temp and MOIIN Tech Clear resins from DMG Digital Enterprises in conjunction with ASIGA UV Max X27 DLP 3D printers. The team 3D printed three common microfluidic designs: 2D monolayer culture devices, pillar arrays, and constricting channels for droplet generators.

The study concluded that 3D printing microfluidic cell-based applications are feasible with MOIIN materials. It is hoped that these observations will open new opportunities for rapid prototyping of new microfluidic channels for biomedical applications.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

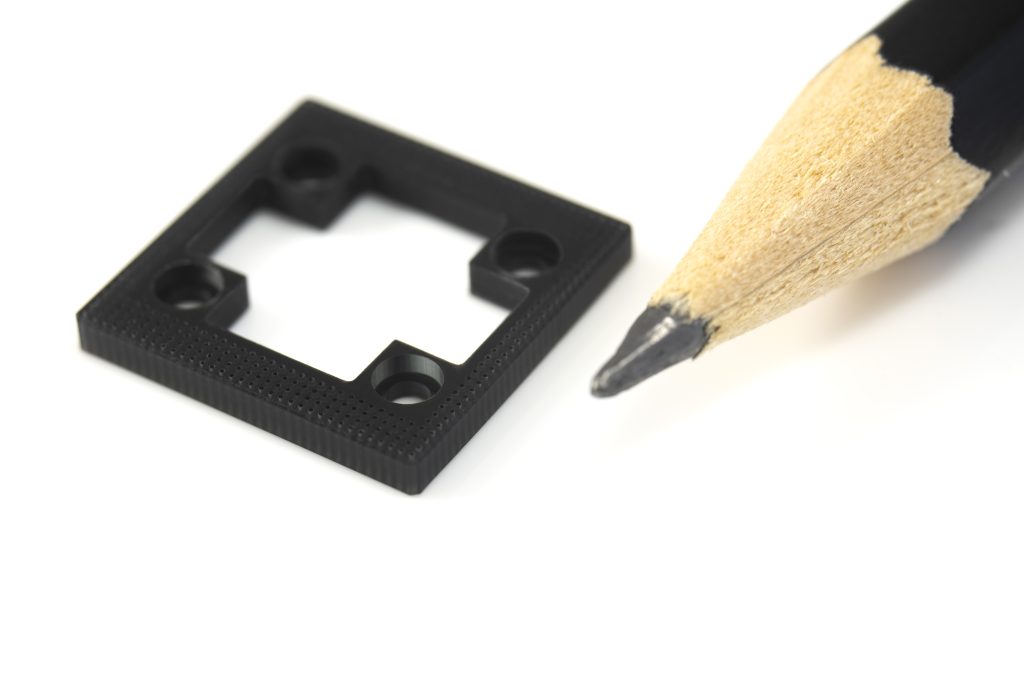

Featured image shows a BMF 3D printed Endoscope. Photo via Boston Micro Fabrication.