Spanish 3D printer manufacturer BCN3D have launched their new BCN3D Omega I60 industrial FFF 3D printer.

The Omega I60 is designed as an all-in-one industrial 3D printer for the production of large and strong prototypes and end-use parts, particularly tooling, jigs, and fixtures. Featuring an upgraded version of BCN3D’s signature Independent Dual Extrusion (IDEX) technology, this new 3D printer offers a large 3D print volume, a high-temperature heat chamber, and a direct-drive high-speed extruder for fast 3D print speeds.

BCN3D has also unveiled their material portfolio for the Omega I60, which includes custom formulations specially selected to cater to specific verticals.

Announced on June 14th during a special live stream event held at their Barcelona headquarters, the launch of the Omega I60 coincides with the BCN3D’s 11th anniversary. Since releasing their first 3D printer in 2015, the BCN3D Sigma, the company has distributed over 10,000 units worldwide across more than 100 points of sale.

Key BCN3D customers include the likes of international automotive manufacturer Nissan, French multinational Saint Gobain, and additive manufacturer of end-use parts for cross-country cars, Prodrive.

Key features of the BCN3D Omega I60

The Omega I60 incorporates an upgraded version of BCN3D’s IDEX technology. According to the company, IDEX is the only extrusion system capable of 3D printing with two independent toolheads simultaneously.

As such, the IDEX system is advertised as doubling productivity, and enabling the production of parts with support without cross-contamination. The Omega I60’s updated IDEX system ensures that the X motors remain stationary during the 3D printing process, minimizing inertia and accelerating 3D print speeds.

BCN3D’s HAQ-XY Kinematics motion architecture has also received an upgrade for the Omega I60. This improved kinematic system includes an optimized pulley system, which is said to significantly reduce torsional moments along the X-axis during the 3D printing process. This removes the potential for deformations to form in the X-axis, ultimately improving the quality of the 3D printed parts.

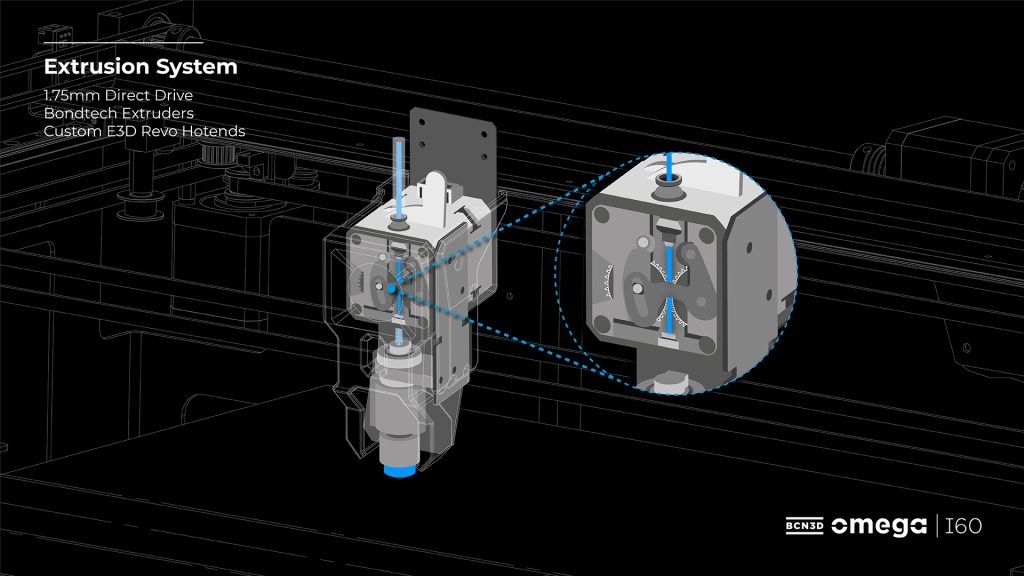

The extrusion system itself is said to be “industry-leading,” with the Omega I60 equipped with 1.75mm direct drive Bondtech LGX Pro extruders. According to BCN3D, this system provides optimized control and precision. Custom E3D Revo hotends are also included, said to be highly reliable and offer easy-swap nozzle change capabilities.

Fast 3D print speed is also key to the Omega I60, with the 3D printer capable of producing parts at 300 mm/s, and accelerate at speeds of up to 10 m/s2. To achieve these high-speeds, the Omega I60 incorporates built-in accelerometers, 32 bit electronics, and a custom version of Marlin 2.1 firmware. BCN3D claims that their new offering is currently the only high-speed 3D printer on the market to include IDEX technology.

An industrial scale 3D printer optimized for the production of large-scale end-use and prototype parts, the Omega I60 also offers a substantial build volume of 450 x 300 x 450mm (60 liters).

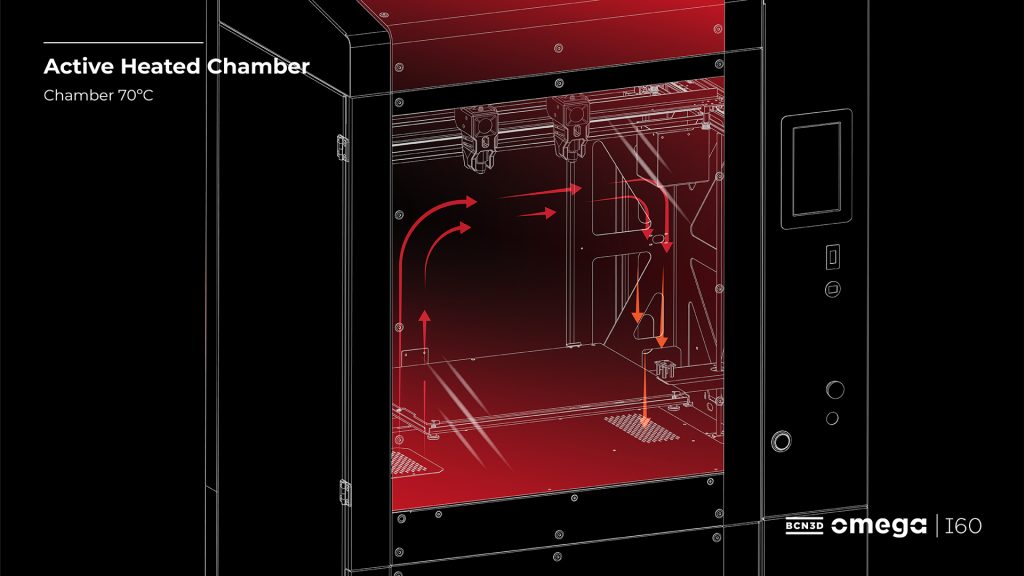

The Omega I60’s active heated build chamber is also notable. This chamber can heat up to 70℃, making it ideal for 3D printing with engineering grade polymers such as ASA, PA, ABS, and reinforced PA.

With optimized temperature control, the chamber is said to minimize the formation of internal stresses by ensuring the uniform construction of 3D printed parts. By heating the chamber close to the glass transition temperature of the materials, the build chamber can effectively prevent issues such as cracking and warping.

The Omega I60 also includes BCN3D’s Material Operations System (MOS), an integrated module which allows users to control the humidity and temperature of the material for a 3D print. The MOS can reach temperatures of up to 75℃, and provides an RH below 10%.

Through the MOS, compromised material can be easily recovered. Additionally, filaments can be preheated before a 3D print begins, essential when using engineering filaments with high heat deflection temperatures. Omega I60 MOS also offers automatic filament loading and unloading, further streamlining the industrial 3D printing process.

The Omega I60 also incorporates XYZ autocalibration. Using piezoelectric sensors, this feature removes the potential for human error, and is said to guarantee first layer adhesion.

Additional features offered with the new Omega I60 include a built-in camera, a flexible build plate, an uninterruptible power supply for secure 3D printing, a barcode sensor for spool and components recognition, a 7” capacitive touch screen, and a andon light.

A HEPA and Carbon filter, Filament Runout Sensor (FRS), Safety Pause function, and an emergency stop button have also been added for optimal 3D print safety. The Omega I60 also includes WiFi and Ethernet connectivity.

BCN3D also offers a material portfolio for the Omega I60, selected to cater to verticals such as tooling, jigs and fixtures, short-run production, masking, large prototyping, production line replacements, and end-use parts. These materials include Omega Impact ASA, Omega Resistant Nylon, Omega Tooling CF, and Omega Support.

The Omega I60 possesses open material compatibility, allowing users to use filaments not provided by BCN3D.

Technical specifications table and pricing

Pricing for the BCN3D Omega I60 starts at €19,995 ($21,995 USD), with the first units set to be shipped on September 15th 2023.

Prospective customers can secure their Omega I60 today by contacting BCN3D at [email protected], or through any of BCN3D’s official distribution partners.

| 3D printing technology | Fused Filament Fabrication (FFF) |

| Architecture | IDEX (Independent Dual Extruder System) |

| Print volume | 450 x 300 x 450mm / 60L |

| Heated chamber temperature | 70℃ |

| Print speed | 300 mm/s |

| Print acceleration | 10 m/s2 |

| Extrusion system | 1.75mm Direct drive Bondtech LGX Pro extruders |

| WiFi / Ethernet connectivity? | Yes |

| Materials | Open filament system |

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the new BCN3D Omega I60 industria 3D printer. Image via BCN3D.