In alliance with Mind in a Box, Avante Technology has announced the release of a royalty-free AMF file format 3D mesh viewer and related source code.

Catering to software developers and system OEMs, the AMFsample source code facilitates easy integration of the AMF file format with CAD and other applications in additive manufacturing. The collaboration aims to develop, publish, and support AMF v1.2 reference software (maintained by Avante Technology, hosted by Mind in a Box), the AMF v1.2 online viewer (in collaboration with Avante Technology, developed by Mind in a Box), and the AMFtools.org public portal (developed and hosted by Mind in a Box). This public portal serves as an information hub for the ISO/ASTM AMF format and standard.

“This sample code minimizes the cost and risk in adding support for AMF,” said Robert Zollo, president of Avante Technology. “Using this ISO standard format enables higher quality and workflow efficiency through the use of AMF’s advanced capabilities. Some government agencies have ISO standard preference policies, so using AMF may provide a competitive edge to vendors too.”

Streamlined file format conversion with AMFsample

Scheduled for release this month, the AMFsample application converts STL files to AMF format, ensuring ISO 52915:20 compliance. Users can visually inspect the 3D mesh with rotation and zoom options, and save in AMF or revert to STL. The accompanying AMFcore source code, in C++, optimized for Linux, Mac, and Windows, will be available for royalty-free download via AMFtools.org in Q1 2024.

Published in 2014 and maintained by the ISO/ASTM TC261 joint technical working group J64, the Additive Manufacturing Format (AMF) specification is the international standard file format for additive manufacturing. Updated twice, with the latest revision in 2020, the specification supports diverse features such as multiple materials, composite materials, colors, assemblies, and lattice structures.

Its openness is evident through its status as the only advanced file format specified in numerous ISO standards for additive manufacturing. The XML-based format is extensible, addressing evolving industry needs and fostering international collaboration through the ISO and ASTM working group J64.

A key feature of the AMF format is its ability to accommodate various meta-data fields, including file ID, unit of measure, version number, author, company, and customizable fields. This flexibility extends to adding copyright, patent information, licensing, and security-related data to user-defined meta-data fields, ensuring the protection of intellectual property. The .url meta-data field provides a secure means to reference the owner’s copyright information without the risk of third-party alterations.

In 2018, Avante Technology launched Emendo Cloud, an advanced STL File Analysis & Repair service for engineers and designers. This high-performance, cloud-based solution excels in repairing hybrid and compound STL files, surpassing traditional algorithms.

Advanced additive manufacturing software rollouts

Recently, Tech Soft 3D launched HOOPS Luminate, a graphics software development kit (SDK) emphasizing photo-realistic and advanced real-time rendering. The SDK provides rendering control, image quality tools, and access to a library of realistic materials. Offering a customizable rendering pipeline, it supports various rendering types, integrating rasterization and ray-tracing.

Developers can use a single C++ API to share data for both real-time and ray-tracing renderings, combining them in a view using hybrid rendering. Compatible with Windows, macOS, and Linux, HOOPS Luminate enhances engineering graphics capabilities, positioned as a key component of the integrated HOOPS SDK suite.

At Formnext 2023, Berlin-based software company 1000 Kelvin commercially launched its AI-driven software, AMAIZE. Collaborating with 3D printer manufacturers like EOS, and clients including a California-based rocket launch provider, the company secured $3 million in funding.

AMAIZE employs physics-informed AI to optimize 3D printing, eliminating the need for costly simulations. Integrated with machine OEMs, it has found success in energy, aerospace, and manufacturing, notably achieving an 80% reduction in support structures and over a 30% cost decrease for a rocket part.

Additionally, software company Oqton introduced Oqton Build Quality software, integrating with Manufacturing OS and 3DXpert for enhanced manufacturing processes. Combining Build Simulation, MOS Build Monitoring, and Build Inspection, it ensures part quality, rectifies errors, and optimizes processes.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

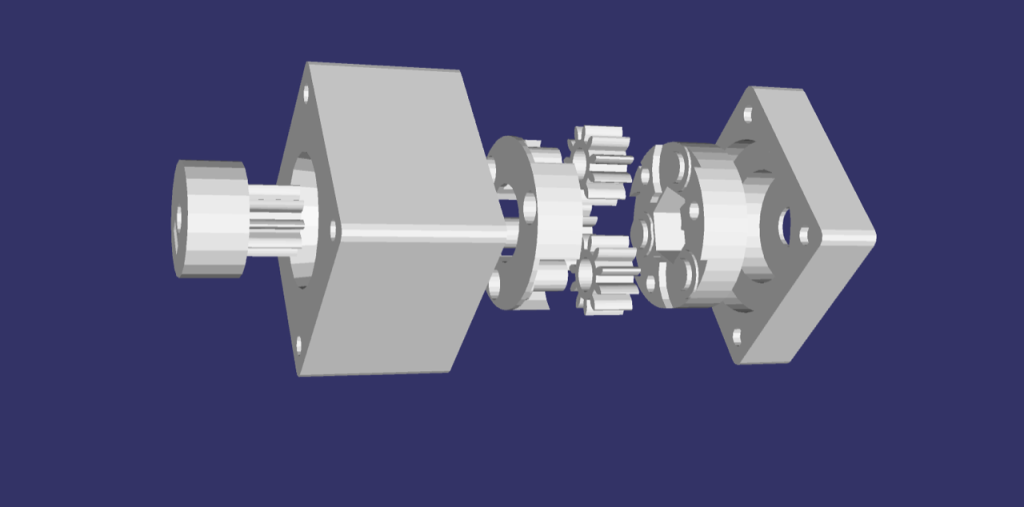

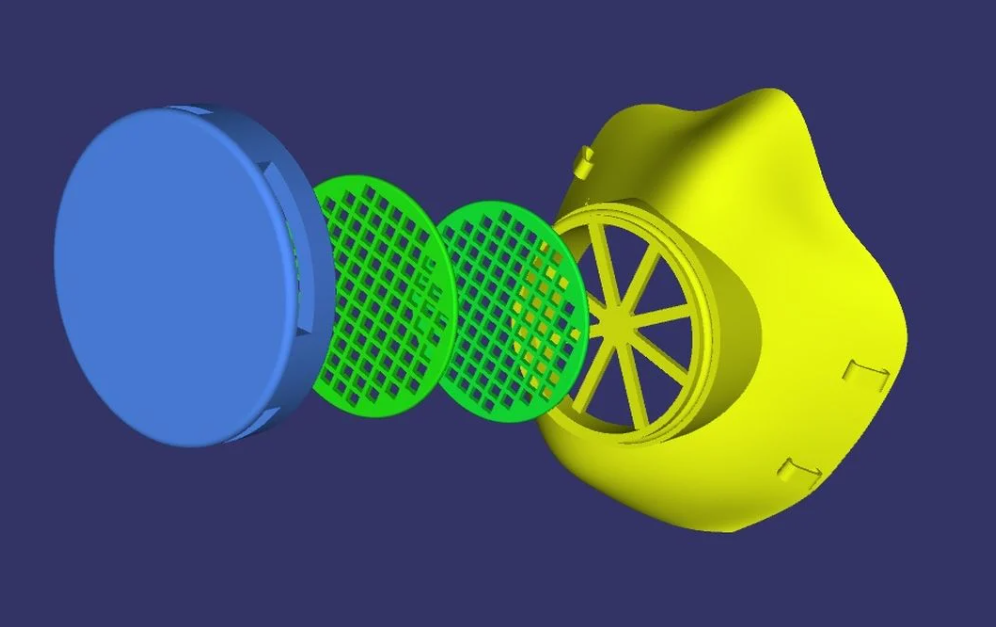

Featured image shows AMF multi-part assembly file. Image via Avante Technology.