German 3D printer and high performance materials manufacturer Apium Additive Technologies has hit a new milestone in the processing of a filament for medical applications.The company’s Medical PEEK 3D Printing, on the Apium M220 Series machine, has met biocompatibility criteria needed to make implants and devices used in the skull and the hand.

Using a filament for FFF desktop 3D printing, this development from Apium promises to “revolutionize patient-specific PEEK implant and medical device production” facilitating professional access to high performance, medical grade materials.

Findings of the most recent biocompatibility tests, implants and devices made made with medical grade PEEK filament using the Apium M220 3D printer will be shown next week at Formnext 2018 in Frankfurt.

Made for permanent tissue contact

Apium medical grade PEEK filament is based on VESTAKEEP® i4 G resin supplied by speciality chemicals producer Evonik. Specially formulated for making long term implantable devices, VESTAKEEP® i4 G exhibits high biocompatibility, biostability, and x-ray transparency making implantation and follow-up appointments easier on the patient and surgeon. The resin meets ISO 10993-1 recommendations “for permanent tissue/bone contact” and is compliant with the ASTM F2026 “Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implant Applications.”

Commonly used in extrusion-based applications VESTAKEEP i4 G is easy to process, a quality shared by Apium Medical PEEK 3D printing. FFF technology makes it easy to produce organic PEEK geometries and, “Due to the low thermal conductivity of PEEK,” Apium says, “the patient’s sensitivity to temperature changes will be lower.”

The medical grade PEEK filament and M220 Series 3D Printers were produced in response to a growing customer demand for end-use, patient-specific medical devices. According to the company, the new production technology means a reduction in lead times and the cost of implant manufacturing. By medical grade 3D printing, production can now be performed on site in hospitals rather than outsourcing to a larger manufacturer.

Desktop 3D printed implants

Though the Apium M220 3D printer itself is not covered by medical production guidelines, the machine is suitable for use in clean rooms, and is suitable for manufacturing medical devices. Full medical certification of devices produced by the machine is a further step, dependent upon geometry and application.

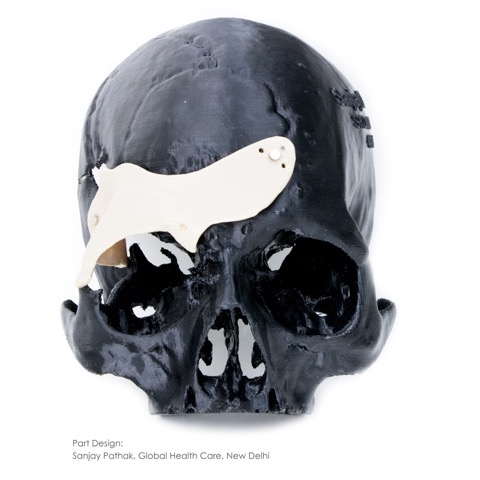

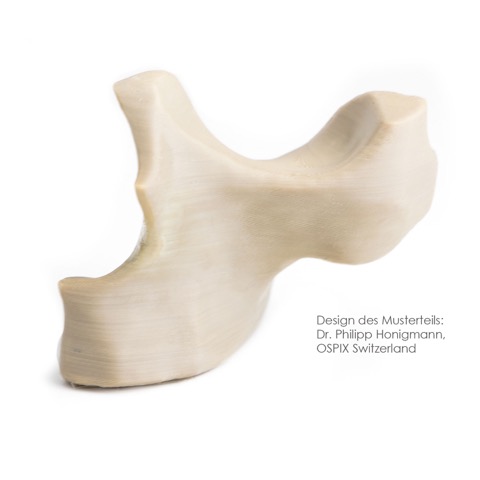

In accordance with the latest biocompatibility tests by the company, Apium Medical PEEK 3D Printing is suitable for making cranial-maxillo-facial implants and devices used in hand surgery. Specifically, Apium 3D printed PEEK implants can be applied to the head, skull, neck, face, jaw and other associated bones, or used to treat injuries and infections to the hand and upper extremities.

For more information about the medical applications of Medical PEEK 3D Printing, visitors to Formnext 2018 are invited to see Apium in Hall 3.1 booth C70 from the 13th through 16th of November.

Disclaimer for Apium M220 and Apium PEEK

The additive manufacturing device Apium M220 is not covered by the guidelines on medical devices. However it is suitable for clean rooms and for the production of medical devices. The necessary certificates of biocompatibility for material and machine can be provided upon request and are included in the delivery of the product.

Some of the statements and claims in this press release may be forward-looking statements or statements of future expectations based on currently available information. Such statements are naturally subject to risks and uncertainties. Actual results or developments may vary depending on changes in the operating environment. Neither Apium Additive Technologies GmbH nor Evonik Resource Efficiency GmbH assume an obligation to update the forecasts, expectations or statements contained in this release.

For the latest medical 3D printing and materials news subscribe to the 3D Printing Industry newsletter, find us on Facebook and like us on Twitter. Looking for jobs in medicine? Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows a 3D printed PEEK finger bone implant (Natural color). Photo via Apium Additive Technologies