The American Petroleum Institute (API) has unveiled a new standard that’s designed to drive the further adoption of additive manufacturing within the oil and gas sector.

With the launch of ‘Standard (Std) 20S,’ the API has effectively introduced a three-tiered criteria, which sets out the technical, quality and qualification requirements for 3D printing end-use-ready rig parts. In practise, the group expects Std 20S to allow oil and gas firms to deploy the technology more consistently, in a way that reduces their carbon footprint and “strengthens their supply chain resiliency.”

“This new standard expands API’s best-in-class safety and efficiency requirements and supports cutting edge operations, helping producers to deploy new 3D printing technologies to meet rising global demand for natural gas and oil products,” said Alexa Burr, API’s VP of Segment Standards and Services for Global Industry Services.

Taking fossil fuel regulation global

Established more than 100 years ago, the API has nearly 600 members hailing from across the natural gas and oil industry, thus it claims to produce, process and distribute the majority of energy in the United States. The organization’s preeminent status has provided it with the clout needed to set standards for the sector, and it now has a catalogue of more than 700 of these, as well as best practices.

Leveraging its accrued oil and gas expertise, the API issues guidance on everything from drill bit and material qualification, to ensuring site safety standards. In order to police these in practise, the organization has introduced ‘Monogram’ and ‘Individual Certification’ Programs, through which it carries out checks on firms’ compliance with certain standards, and recognizes those working closely to industry codes.

According to the API, many of its standards have been incorporated into U.S. federal law, and they’re “widely-cited by the international regulatory community.” As a result, the group has increasingly sought to go global with the ambition of improving “the safety and viability of the U.S. oil and gas industry,” and addressing the sector’s wider environmental challenges.

Introducing ‘API Standard 20S’

Launched in October 2021, API Standard 20S covers the production, marking and tracking of ‘Additively Manufactured Metallic Components for Use in the Petroleum and Natural Gas Industries.’ Specifically, the document introduces measures that oil and gas firms need to follow, if they want to manufacture fit-for-purpose powder bed fusion (PBF), directed energy deposition (DED) or binder jet 3D printed parts.

Standard 20S is essentially built around three additive manufacturing specification levels (AMSLs), which define the rising technical, quality and qualification requirements that need to be met to gain API ‘AMSL grades 1-3.’ However, to achieve this certification, oil and gas firms will also need to meet wider standards, around issues like training, inspection, equipment, material testing and quality control.

Once implemented, the API anticipates that its AMSLs will hasten the sector’s 3D printing adoption, and result in the roll-out of optimized parts that “drive efficiency, safety and technological advancements across all segments of the industry.”

The organization also sees Standard 20S as a way of helping oil and gas firms reduce their supply chain dependency, while making progress towards the goals outlined in its Climate Action Framework. In a report published earlier this year, the API committed to working for a “lower-carbon future” via the “acceleration of technology and innovation,” thus it has now turned to AM in pursuit of these aims.

“Employing innovation is one of the many approaches that our industry is taking to reduce carbon emissions, as outlined in API’s Climate Action Framework,” added Burr. “The ability to deploy innovative technology and bring critical manufacturing closer to the point of use, reduces stress in the supply chain, while driving down Scope 3 emissions and maximizing production capability.”

Following the introduction of Standard 20S, the API says it’s now working on a similar set of guidelines for polymeric 3D printed parts, adding that its latest announcement “is only the beginning of the work that will be done in this space.”

Those interested in finding out more about API Std 20S can purchase access to the document via the organization’s dedicated online store here.

AM’s oil and gas opportunity

Although the API describes its new standard as a “first-of-its-kind document,” it’s actually similar to those already developed by the likes of DNV GL, which has also identified the potential of 3D printing within the oil and gas sector.

As long ago as 2017, the company introduced its first classification guideline for oil, gas and maritime 3D printing, and it has since followed this up with a service specification document, designed to expedite the technology’s adoption. Having met these standards, part provider Protolabs gained ‘Qualification of Manufacturer’ certification, for its metal 3D printing offering from DNV GL in May 2021.

Said to be the first PBF manufacturer to meet DNV GL’s lofty standards, Protolabs was awarded qualification specifically for its Inconel 718 superalloy direct metal laser sintering (DMLS) offering. Using its technologies, the firm says it’s now possible to produce complex, ultra-resistant end-use rig parts, and the results of its ‘Decision Time’ survey indicate there’s a growing demand for AM within oil and gas too.

Elsewhere in the industry, energy services provider Hunting PLC has also indicated that it plans to begin 3D printing oil and gas components, following its acquisition of a stake in Cumberland Additive. While the firm hasn’t revealed exactly how it intends to deploy the technology, it says that its investment provides it with “new market opportunities,” in “sectors complementary to its core competencies.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

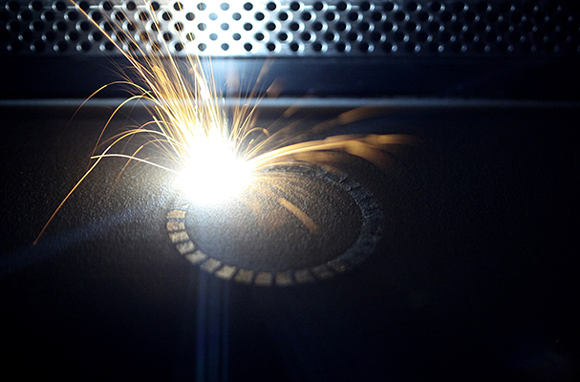

Featured image shows an offshore wind farm. Photo via Protolabs.