Following the launch of the Photon Mono M5s 3D printer, 3D printing company Anycubic has introduced its new Kobra 2 FDM 3D printer, which aims to provide users with a high-speed printing capability and improved user-friendly experience.

According to the manufacturer, Kobra 2 is an “ideal choice” for individuals and hobbyists seeking rapid printing and cost-effective 3D printers. It boasts several notable features such as 5x speed, a dual-gear direct drive extrusion system, an upgraded cooling fan, a dynamic structure, the Anycubic LeviQ 2.0 auto bed leveling system, and more.

“Turning your ideas into reality with 3D printers quickly can be a challenging process, especially with regular speed printers. However, Kobra 2 has revolutionized the process by making it more accessible and efficient,” said James Ouyang, Vice President of Anycubic. “The 3D printer can deliver fast prints while maintaining high-quality results, enabling creators to have more time to focus on their ideas rather than the production process.”

Achieving fast prints and results

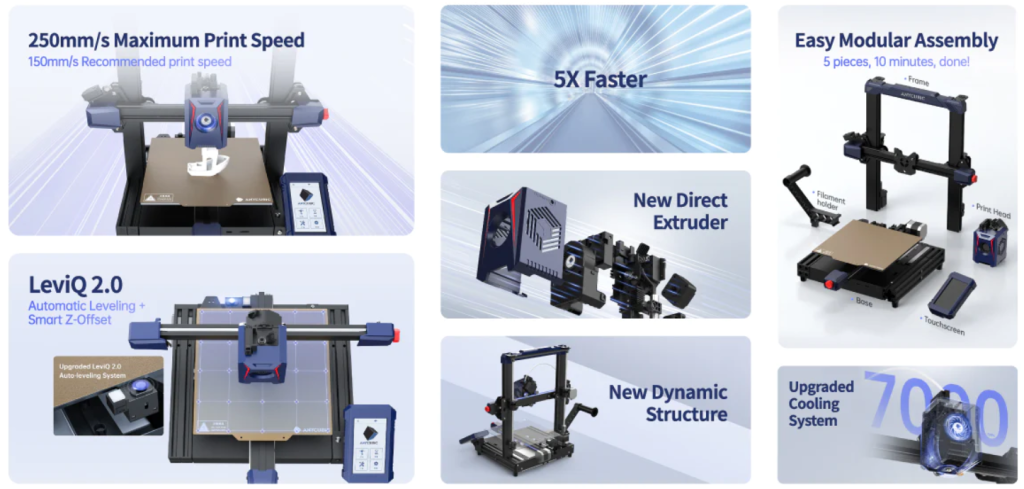

The Kobra 2 has a default print speed of 150mm/s and a maximum print speed of 250mm/s. This enables it to efficiently produce a Benchy model with a 0.28mm layer height in as little as 30 minutes. Several other features of the Kobra 2 contribute to its high printing speed.

The Kobra 2 uses a direct drive extrusion system with a 4:1 gear ratio, providing a secure grip on the filament preventing any slippage, and ensuring precise extrusion and flow control even at high speeds. To compensate for slower extrusions during speed changes, the printer increases the extrusion rate. This is supported by the 60W high-power hot end of the Kobra 2, which enables faster filament melting and improved flow, leading to enhanced print speed.

Kobra 2 utilizes an upgraded cooling fan to efficiently cool down the extruded filament. It incorporates an optimized dissipation design and operates at a spin speed of 700rpm. This effective cooling process allows for rapid cooling of the prints, ensuring that the subsequent layer can be applied with accuracy and precision.

The 3D printer also utilizes double metal spindles and SG15 bearings on its X and Y axes, reducing friction for smoother, faster, and more durable movements compared to regular wheel structures. This results in smoother and faster movements that are also more resistant to wear compared to the regular D shape wheel structure. The Z-axis incorporates a double screw motion mechanism, enhancing speed, reducing resistance, and maintaining levelness on the X-axis. These features minimize layer lines and deliver better results, even at high speeds.

Simplifying the auto-bed leveling process

Anycubic believes auto-leveling functions are increasingly considered essential in FDM 3D printing. They simplify and expedite the leveling process compared to the manual knob adjustments required in older-generation printers. Consequently, Anycubic has introduced the Anycubic LeviQ 2.0 auto-bed leveling system to streamline this process.

This system is equipped with an inductive sensor capable of detecting distances or gaps on metal surfaces without the need for direct contact. This sensor enables automatic compensation for any irregularities in the print platform. Additionally, the printer incorporates a smart Z-axis compensation module that enables automatic adjustment of the nozzle height and precise adjustment of the Z-offset. These features significantly simplify the leveling process, particularly for new users.

Easy to use and reliable

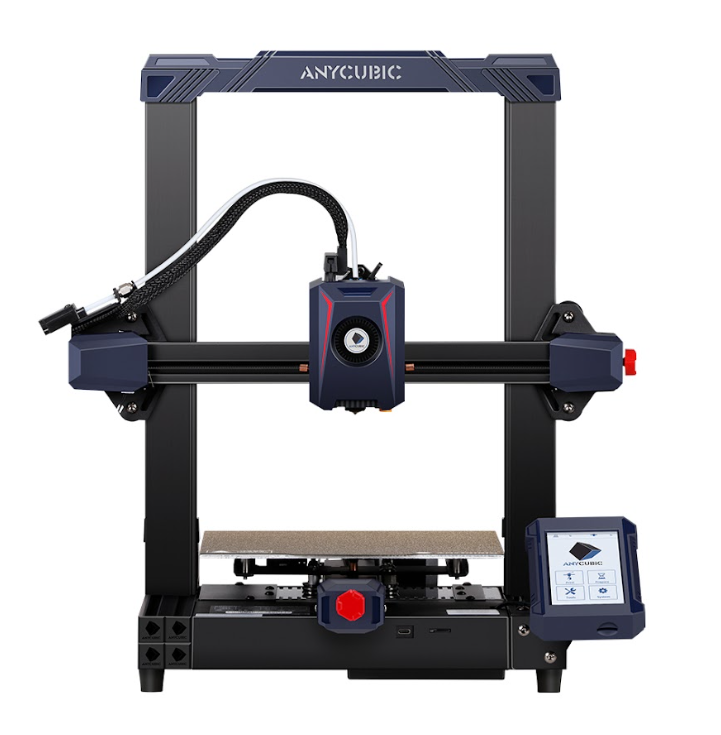

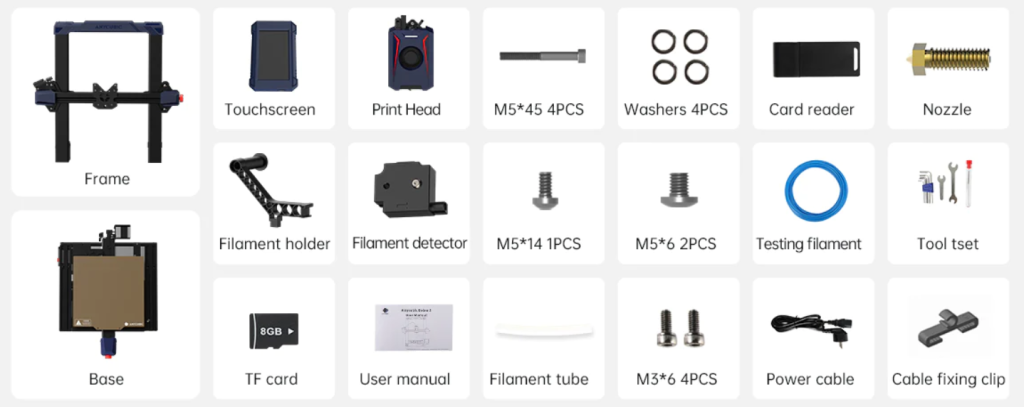

The partially assembled Kobra 2 requires no soldering or complex mechanical assembly, allowing “3D printing novices” to set it up in just 10 minutes. Its user-friendly interface features a responsive 4.3-inch color touchscreen LCD mounted on the right side, providing convenient access during printing. The textured surface effectively secures hot prints, which can be easily slid off once cooled, without requiring tools. This feature enables effortless removal of prints, including larger or adhesive PETG prints.

The Kobra 2 3D printer includes a power-loss recovery feature that allows it to resume printing from where it left off in the event of an unexpected power outage. It is equipped with a filament run-out sensor that detects when the printer runs out of filament and automatically pauses the printing process. This feature helps prevent printing errors and ensures a smoother printing experience.

Technical specifications and pricing

| Machine Weight | 8.4kg | Machine Dimensions | 19.1x173x171in/486*440*435mm(HWD) |

| Printing Volume | 3.2gal./12.1L | Printing Dimensions | 9.8×8.7×8.7in./250x220x220mm(HWD) |

| Nozzle Temperature | ≤500F/260℃ | Nozzle Size | ø 0.4mm (replaceable) |

| Hotbed Temperature | ≤230F/110℃ | Printing Speed | 9.8in./s or 250mm/s(Max.) 5.9in./s or 150mm/s(Typ) |

| Z axis | Double-Threaded Rod | Control Panel | 4.3″ LCD Touch-Control Screen |

| Printing Material | PLA/ABS/PETG/TPU | Power Button | Power-Loss Recovery |

| Data Input | MicroSD Card | ||

The Kobra 2 3D printer will be available on sale in the US from May 25th, 2023, at 9:00 am (EDT) for $269, and in Europe from June 1st, 2023, at 9:00 am (CEST) for €299. Users can subscribe for updates and buy from the official Anycubic store, Amazon, eBay, Walmart, and AliExpress.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Kobra 2 enables 5x faster 3D printing and contains auto-bed leveling system to streamline the process. Image via Anycubic.