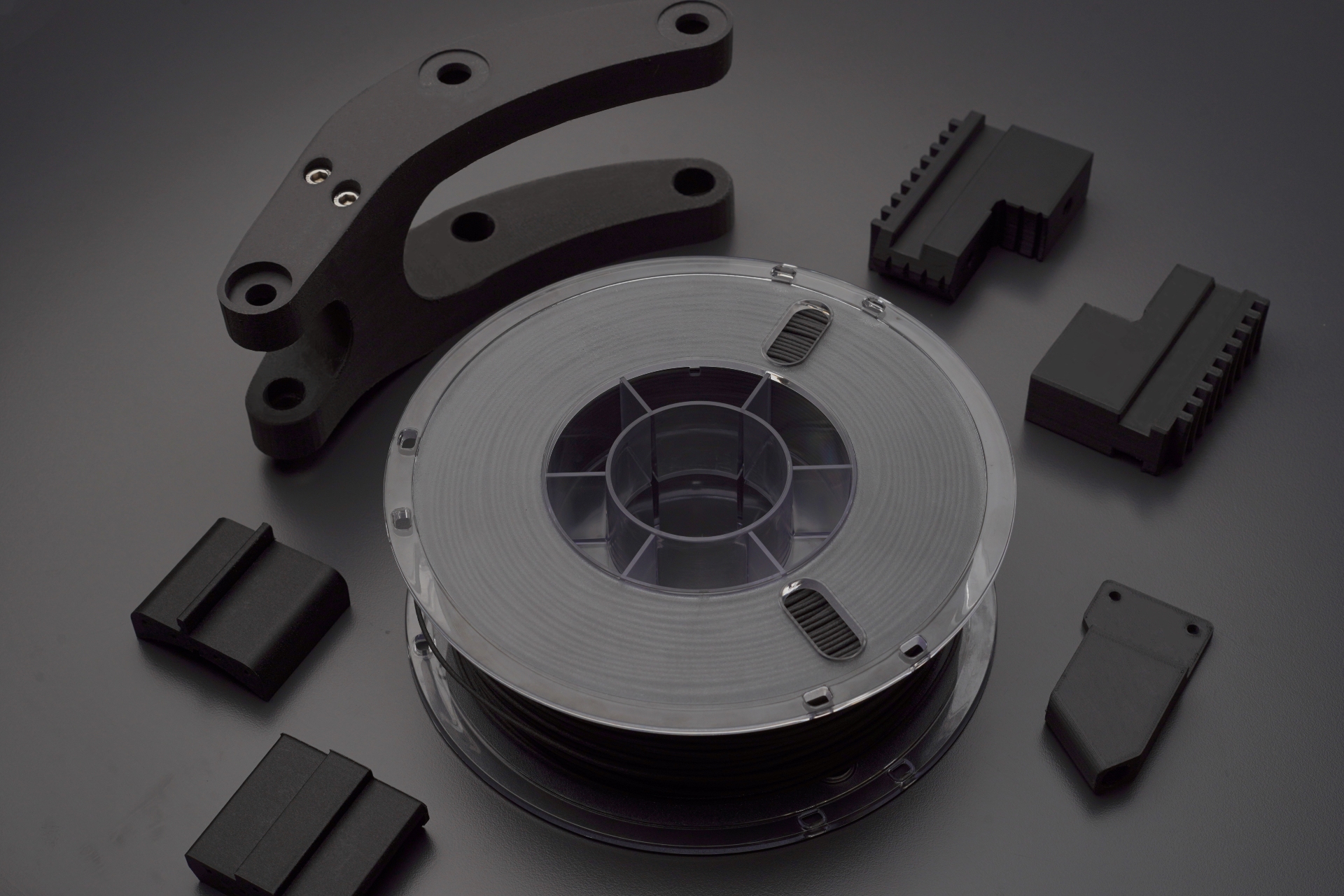

Continuous fiber 3D printing specialist Anisoprint has announced the launch of its very own printing package for the fabrication of high-strength composite parts – Desktop Anisoprinting.

The turnkey product is intended as a comprehensive toolkit for new and prospective customers looking to get started with continuous fiber 3D printing. Alongside the Anisoprint Composer 3D printer, proprietary software, and reinforcement materials, customers will also receive two purpose-built polymer filaments, revamped printing profiles, and a set of training courses from Anisoprint’s in-house technical experts. The idea is that newcomers to the process will be able to dive right in as if they are surrounded by the company’s own engineering team.

Fedor Antonov, CEO of Anisoprint, told 3D Printing Industry: “Adopting new technologies is always a challenge, but it’s the only way to compete and survive in the modern economy. We want to support our customers in this journey and help them make a smooth transition. That’s why we are launching Desktop Anisoprinting – everything you need to start 3D printing with composites and to introduce yourself to the future of manufacturing.”

Polymers, printing profiles, and educational programs

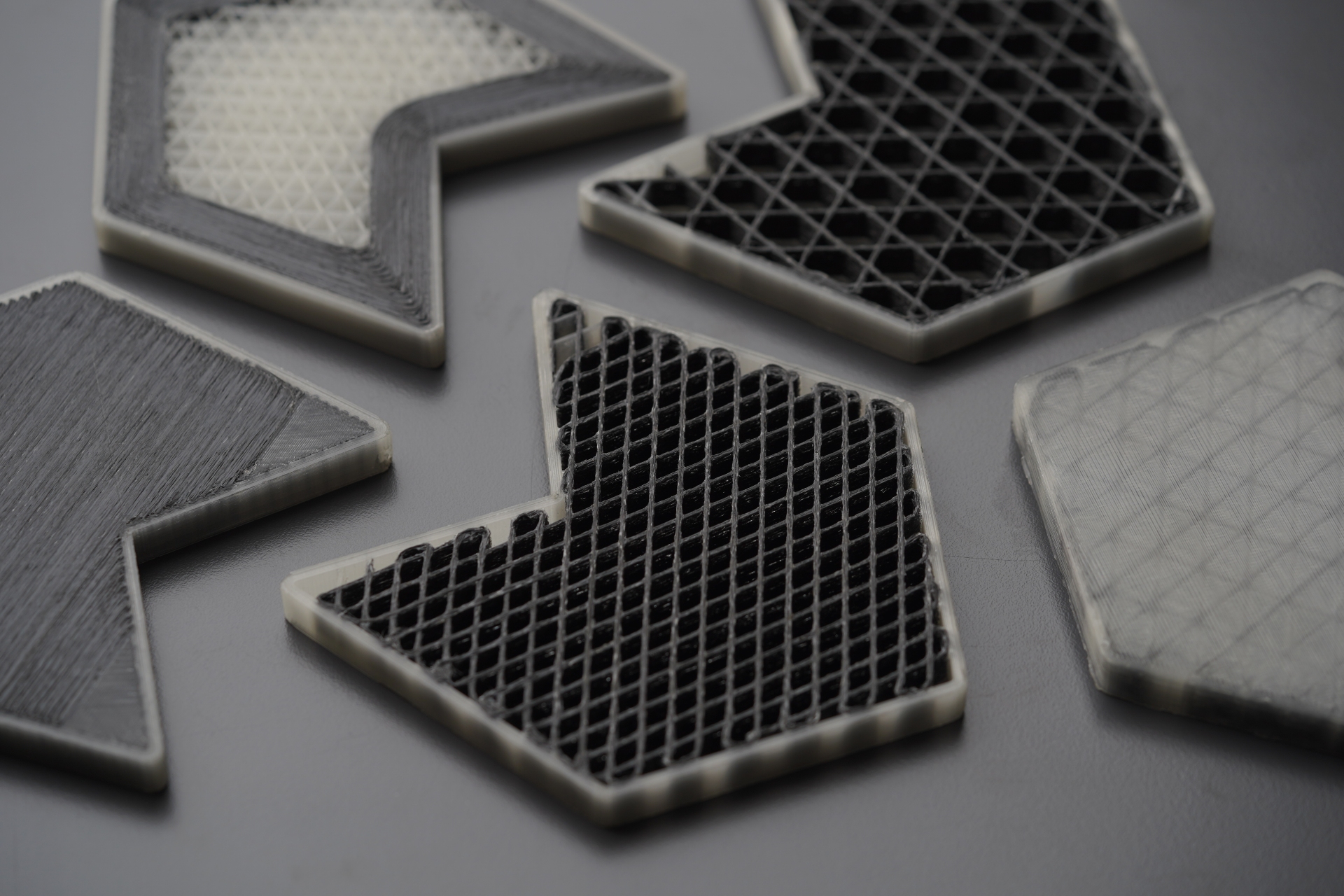

The kit contains two distinct variants of polyamide, CFC PA and Smooth PA, formulated by leading polymer developer Polymaker. Both materials have been fine-tuned specifically for Anisoprint’s proprietary Composite Fiber Co-extrusion (CFC) 3D printing technology, whereby preliminary impregnated and cured continuous fibers are extruded alongside the main polymer matrix – using the same extruder – to produce a bi-matrix composite part.

CFC PA, with its excellent mechanical properties, was designed to promote adhesion between the plastic and fiber. Smooth PA is intended for the outer shells of parts to deliver high surface qualities with no additional post-processing.

The company’s Aura slicing software also now contains verified printing profiles for a wide range of polymer filaments. Developed by Anisoprint’s application engineers, the ready-made parameter sets include optimized temperatures, speeds, layer thicknesses, and even cooling profiles – all designed to eliminate the otherwise tedious and costly trial-and-error approach to composite 3D printing.

The cherry on the top of the package is the targeted training course delivered by the firm’s in-house experts with over a decade of experience in composite materials development. The programs cover a vast range of topics such as the basics of composites and design, material properties, and hardware operation, with different user experience levels. Some of the courses will be online video-based, others will include interactive quizzes and tasks, and a select portion can be taken completely offline.

Getting started with Desktop Anisoprinting

Speaking to Antonov, the CEO does not believe that 3D printing with continuous fibers necessarily needs to be difficult, but it is inherently different. This discrepancy between CFC and other 3D printing processes is what the Desktop Anisoprinting package ultimately aims to eliminate.

He adds: “Everyone involved with the 3D printing industry knows that you need a lot of experience to achieve the best results in a short space of time, especially on an open system. It is not enough to only master FDM technology if you want to understand all of the aspects of printing with our CFC technology. Continuous fiber 3D printing also requires a significantly different design approach, which is covered in our educational courses.”

Desktop Anisoprinting will be available to purchase from late November onwards, with quotes available to request on the company’s website. Readers interested in learning more about the product can register for a free webinar being delivered by Antonov on the 15th of October.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ‘Desktop Anisoprinting’ continuous fiber 3D printing package. Photo via Anisoprint.