The day started off beautifully at Fort Mason Center in San Francisco. Coming from a punishing East Coast winter that was bullying the spirit of the population into submission, the sunny climate of San Francisco with its accompanying warm breeze felt almost mystical. Walking down to REAL 2015 in absolutely pristine weather, surrounded by the beautiful Pacific Ocean centered by the Golden Gate Bridge, couldn’t have felt better.

As I first entered the Herbst Pavilion, I got the feeling that something big was happening for the first time. I already knew from the event’s website that the sheer variety of speakers and technologies represented at REAL was mind boggling. I couldn’t wait to explore them all and crystallize my conception of Reality Computing at this early stage in it’s evolution. I quickly registered to get my pass from the friendly staff, and walked right in with zero hassle or wait.

I passed a massive cage for drone demonstrations, and an enormous Shapify booth decorated with Artec’s Eva and Spider laser scanners.

At the hotel the night before, I had heard that the event hall was in the process of being scanned from the air by drones: Reality Computing REAL 2015 at REAL 2015. Nice touch. Next, I passed a small stage and two Ember DLP SLA 3D printers quietly humming next to part of the team that built them.

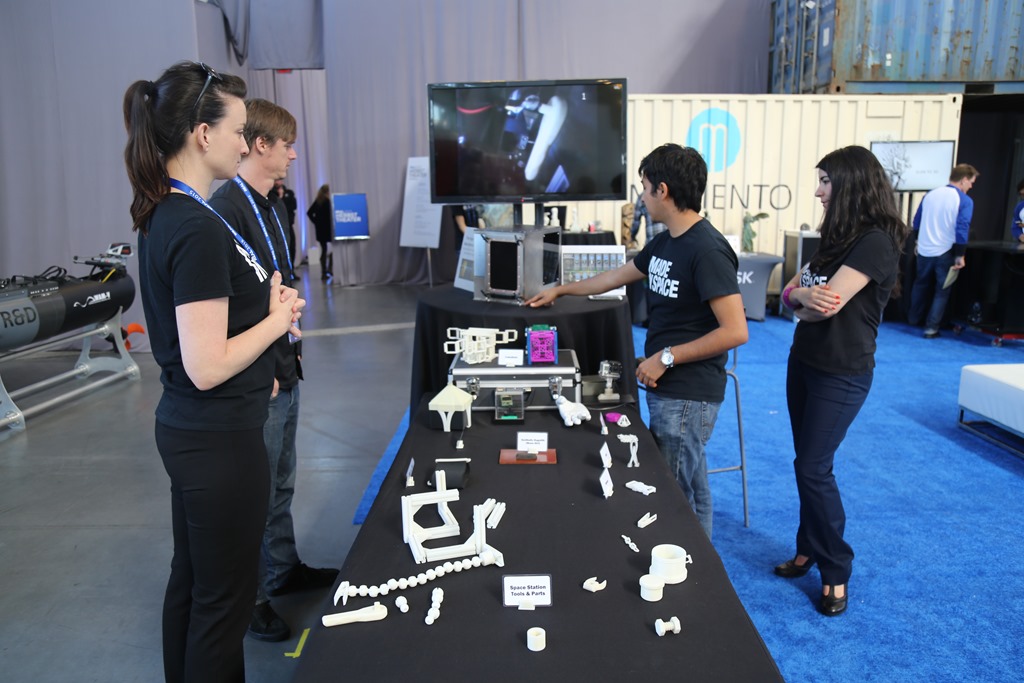

Next to the Autodesk Ember booth, I caught a glimpse of the Made In Space display and team, glancing at the infamous 3D printed ratchet which first made headlines as the first object to be email-beamed to the International Space Station and 3D printed in space.

The microgravity 3D printer was the centerpiece of the booth, and I couldn’t wait to check it out a bit later. Distracted by the microgravity printer, I did a double take as I walked by this:

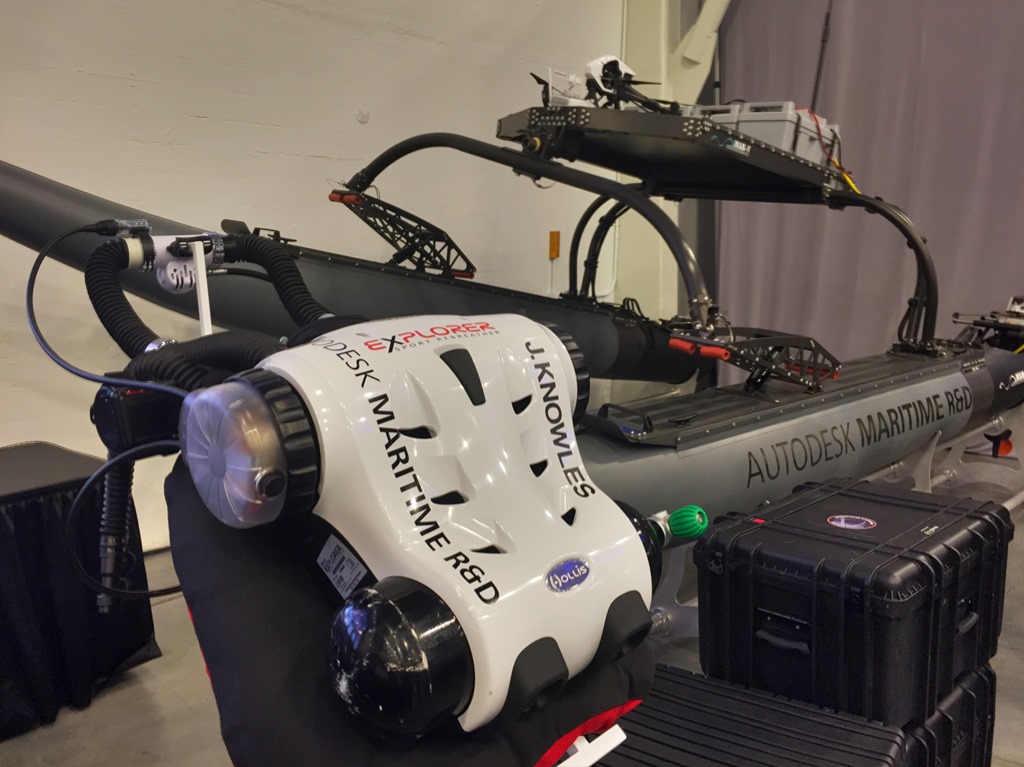

Autodesk Maritime R&D? J.Knowles stands for Jonathan Knowles, and he is Autodesk’s Director of Strategic Initiatives as well as the head of Autodesk’s Maritime Research & Development group, which organizes and conducts ocean fieldwork.

I passed a second stage with a huge viewing screen and made my way to the front of the venue. After some coffee and a light breakfast, everyone filed into the auditorium to kick off the 1st ever REAL event. The introductory speeches of REAL 2015 were given by the co-chairs of the event, Robert Shear (Sr. Director and GM, Reality Solutions Group) and Professor Alonzo Addison.

One of the best points of the opening conversation was to iterate that they didn’t just want to put on a either a 3D sensing, 3D printing, 3D software or AR/VR show. Though these technologies are extremely interesting in their own right, REAL 2015 was about bringing them together to appreciate how interconnected they’re becoming. What I took away from this conversation was that REAL 2015 was about recognizing that a new, larger world of engineering and design is forming from the increasing interconnectedness of the 3D software, 3D sensing, augmented reality, virtual reality, and 3D printing industries. Sensing technology is everywhere; parallel computing is easier and less expensive than ever, thanks to the ever-expanding cloud; processing power keeps increasing; and 3D printing is moving out of a tremendous hype cycle and settling into a new period of innovation and integration throughout a growing array of industries.

During Ethyor Bender’s presentation for it occurred to me that this concept of an umbrella industry to incorporate all of the above technologies, including 3D printing, might best be exemplified by the work of UNYQ, designers and producers of custom 3D printed prosthetics. Repeatedly throughout REAL’s marketing materials, you’ll notice three words used to represent Reality Computing: capture, compute, and create. UNYQ’s process for utilizing these three C’s is pretty straightforward:

Capture = Capture the point cloud 3D data of the scanned limb.

Compute = Prepare the 3D data for analysis, modifications and 3D printing.

Create = 3D Print the 3D model of the prosthetic limb, customized to be patient-specific.

I would probably add a fourth element to the capture, compute, create equation: cost. If you take the case of prosthetics, the cost effectiveness of scanning, modeling, and 3D printing prosthetics has yielded a new standard of innovation that intersects the medical prosthetics, 3D scanning, 3D software, 3D printing, and digital fabrication industries to create a new and improved singular process. And this process is just one of many examples of Reality Computing already occurring within the 3D printing industry.

If REAL 2015 was any indicator of a productive convergence of industries, Reality Computing is going to change engineering, design, and additive manufacturing for years to come. I’ll be covering REAL 2015 for the duration of this week, and I’m excited to share everything from the highlights to interesting marginal moments that made this the most stimulating summit I’ve ever been to.

For more great pictures of REAL 2015, also please check out Shaan Hurley’s blog Between The Lines.