UK-based post-processing specialist Additive Manufacturing Technologies (AMT) has received an Innovate UK grant worth £87,000 to develop a new organic solvent designed specifically for the post-processing of elastomer materials.

Designed specifically for thermoplastic elastomers such as TPU, the solvent can be used in AMT’s PostPro Chemical Vapor Smoothing Process. The company will use the grant to further fast track its research and development program to produce a new generation of bio-renewable chemistries, with the goal to improve sustainability within the 3D printing post-processing market.

“Developing sustainable solutions that further the industrialization of additive manufacturing is our primary focus at AMT, and we’ve already proven that with our PostPro Chemical Vapor Smoothing technology,” said Dr. Konstantin Rybalcenko, Global Head of R&D at AMT. “By utilizing the Innovate UK Sustainability funding to develop this new consumable for elastomers, we’re furthering the capabilities of our technology in an even more sustainable way for our customers.”

A new-generation organic solvent

AMT was awarded £87,000 as part of Innovate UK’s Sustainable Innovation competition, which was created to assist all sectors of the UK to recover, grow, and create new opportunities as they emerge from the global Covid-19 pandemic.

AMT has leveraged the grant to produce a new organic solvent designed specifically for the post-processing of thermoplastic elastomers such as TPU, TPE, TPA, and others.

The new solvent is bio-renewable and can be used in AMT’s PostPro Chemical Vapor Smoothing process alongside the company’s current organic consumable offering. At present, AMT is using the solvent for prototyping applications, and the final product will be globally available in Q2 2021.

“We look forward to working with OEM industrial partners to implement this next-generation consumable into 3D printing factories across the globe,” added Rybalcenko.

AMT has been busy recently, having closed a £2.5 million funding round in March that brought the total amount raised by the company to more than £7 million. The proceeds will be used to accelerate the company’s growth and product development plans for the industrial 3D printing sector.

The announcement followed AMT’s recently agreed partnership with multinational printing firm HP to provide end-to-end post-processing services for its Multi Jet Fusion (MJF) technologies to its industrial customers. Only last week, the company announced it had teamed up with Japanese electronics manufacturer Mitsubishi Electric to speed up automated additive manufacturing post-processing with the development of a fully-automated post-processing machine for 3D printed parts that incorporates articulated robotic arms.

PostPro Chemical Vapor Smoothing technology

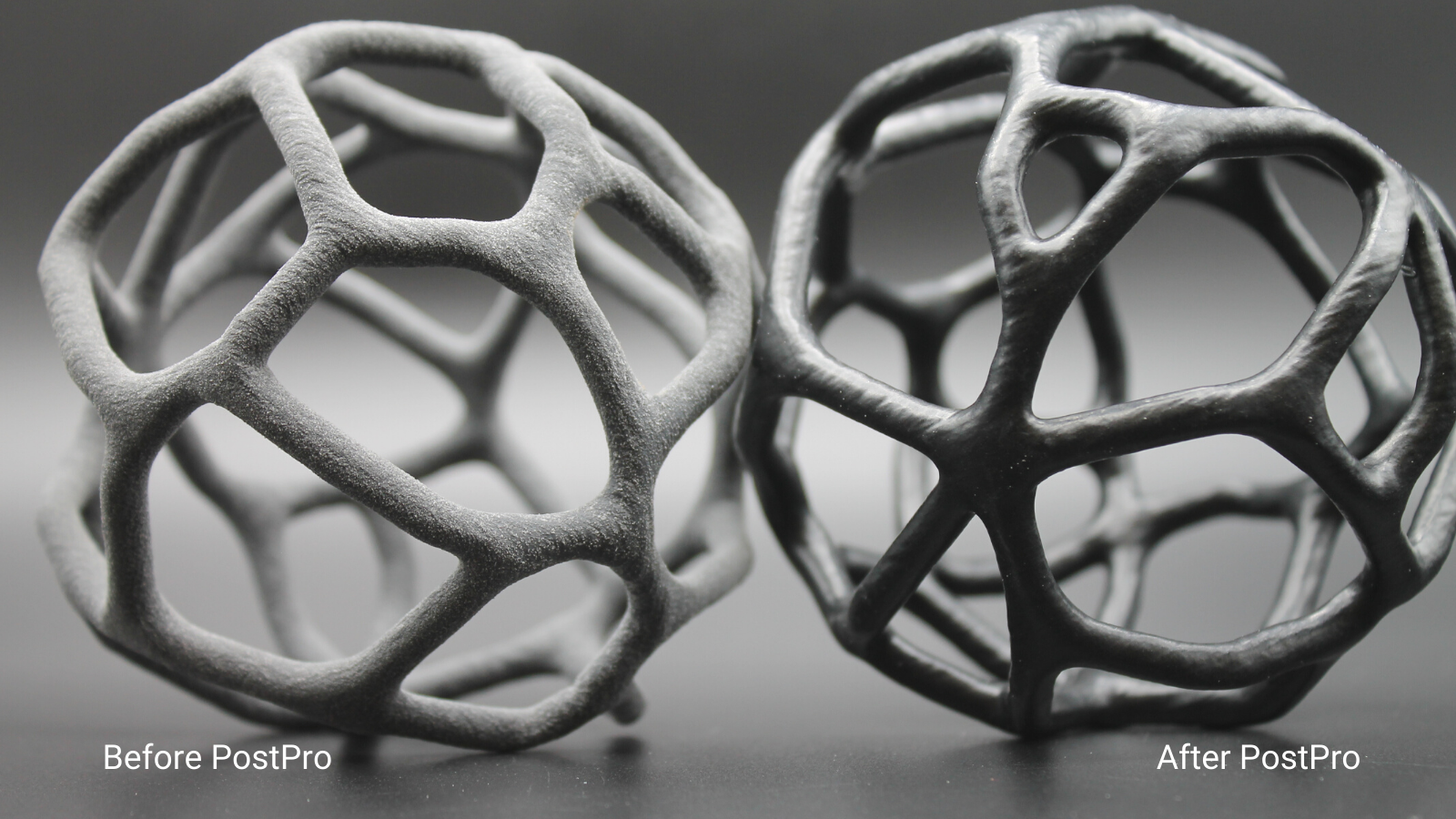

Launched in 2018, AMT’s PostPro technology is a patented, fully-automated chemical vapor smoothing process for 3D printed parts. The technology seeks to provide notable cost-savings to manufacturers by replacing manual post-processing steps.

The process provides a seamless surface finish to thermoplastic 3D printed parts, by blasting parts suspended in a chamber with a highly-potent solvent to remove porosities and surface imperfections. PostPro is designed with a closed-loop system, whereby a large condenser is used to reclaim the solvent vapor after processing and pump it into a sealed, stainless steel container. Here, the solvent vapor is collected and recycled by AMT, resulting in no chemical waste.

The technology received patent protection in the UK in July 2020, and provides sealed surfaces for highly regulated applications, such as those in the medical sector, improved mechanical properties for high-performance applications, and improved aesthetics for consumer parts.

The technology also uses no carcinogenic, mutagenic, or reprotoxic (CMR) category one chemicals, or flammable or explosive chemicals, within the process. The chemicals used in the PostPro process include a proprietary mix of organic solvents developed by the University of Sheffield which are REACH regulated and approved for medical use.

Recent developments in 3D printing post-processing

Ongoing advancements in automated 3D printing post-processing technology are bringing the industrialization of additive manufacturing ever closer.

Post-processing specialist DyeMansion is seeking to reduce process times and increase load capacity with the development of three new post-processing systems – the Powershot C Performance (cleaning), Powershot S Performance (surfacing), and Powershot DUAL Performance (cleaning and surfacing), which are engineered to complement high-volume 3D printing of industrial components on the shop floor.

Meanwhile, Polish 3D printer manufacturer Sinterit has launched its new Powder Handling Station (PHS) which is designed to streamline and accelerate the powder recovery process during post-processing into one ergonomic platform.

Elsewhere, Chinese 3D printer manufacturer Farsoon launched a new polymer Powder Management System and External Cooling Station for its 403P system, with the new post-processing units focused on delivering speed, powder management, efficiency, and ease-of-use benefits, while SLA 3D printer manufacturer Nexa3D unveiled its new xCure post-processing system that is reportedly capable of post-processing photoplastic-based parts on a “production scale.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows TPU 3D printed part after PostPro Chemical Vapor Smoothing. Photo via AMT.