The past week has seen several 3D printing funding announcements from both the U.S. National Additive Manufacturing Innovation Institute, America Makes, and the UK’s innovation agency, Innovate UK.

America Makes has awarded $2.3 million in funding across three project calls which are seeking to accelerate the adoption of additive manufacturing and address supply chain needs. A total of 10 teams have been selected to participate in the project calls, which were initially announced in July.

Meanwhile, Innovate UK has awarded Fixie, a 24/7 3D printing service for built environment professionals, and Enable Manufacturing, a UK-based metal 3D printing service provider, grants to expand their additive manufacturing activities within their respective sectors.

America Makes project calls and awardees

The successful project teams will receive funding worth a collective $2.3 million from the Air Force Research Laboratory (AFRL)‘s Materials and Manufacturing Directorate, Manufacturing and Industrial Base Technology Division, and the Office of the Under Secretary of Defense for Research and Engineering OUSD(R&E).

“With the July project call announcements, we also unveiled a new project call process to further enhance collaboration among our membership community and stakeholders, streamlining engagement with the Insitute,” said Brandon Ribic, America Makes technology director. “This change made a difference in the strong member response and high-impact submissions we received. As a result, we identified and secured additional funding from OUSD(R&E) to award more projects in these critical areas.”

Open Project Call

The Open Project Call 2020 was divided into three focused technical areas, the first of which revolved around utilizing machine learning and artificial intelligence (AI) to predict the quality of 3D printed material. The first of the teams chosen to participate in this area is made up of Senvol with Northrop Grumman, the National Institute for Aviation Research (NIAR), Wichita State University (WSU), Stratasys Direct Manufacturing, and Pilgrim Consulting.

Pennsylvania State University and the Applied Research Laboratory (ARL) form another team, while Open Additive, Addiguru, and Wright State University make up another. The fourth and final team to focus on this technical area is made up of the University of Dayton Research Institute (UDRI) with Northrop Grumman, ZEISS, Open Additive, and Macy Consulting.

The second technical area under the Open Project Call centers around the cross-validation of physics-based modeling and in-situ process monitoring of metal 3D printing. The team investigating this area include Pennsylvania State University ARL and Applied Optimization Inc. For the third technical area, ASTM International and Auburn University will collaborate to explore cybersecurity for additive manufacturing training.

Hypersonic Project Call

The Hypersonic Project Call aims to overcome the identified shortcomings of traditional manufacturing processes through maturing technologies surrounding the 3D printing of high-temperature metals for hypersonic capabilities, namely through improving cost, performance, and lead time.

The project call is split into two technical areas, the first of which seeks to achieve reliable manufacturing of complex scramjet flowpath components. GE Additive, Aerojet Rocketdyne, and NASA Marshall Space Flight Center have been chosen as one team for this project, while 3D Systems and Lockheed Martin form a second.

The second technical area, which will investigate the gradient printing of material systems relevant to hypersonic applications, will see input from Boeing, QuesTek Innovations, and RPM Innovations (RPMI).

Rapid Innovation Call (RIC)

Government-driven, the RIC’s technical focus has been directed by the U.S. Army alongside the Food and Drug Administration (FDA) to quantify the tensile behavior of 3D printed metal lattice structures. Ohio State University has been announced as the chosen team to embark upon this project.

The earlier-announced Member Driven Rapid Innovation Call is expected to get underway soon.

Fixie awarded £100K from Innovate UK to open up 3D printing to architects

As part of its Sustainable Innovation Fund, Innovate UK has awarded Fixie £100,000 in funding to build an automated online platform that will significantly speed up the process of creating physical models from digital 3D designs for architects. The firm, which was founded in 2019, will be supported by the University of Sheffield Advanced Manufacturing Research Centre during the project, which seeks to make 3D printing a more accessible and affordable tool for architects.

“We started Fixie to give more architects the opportunity to benefit from rapid prototyping,” said Ronan O’Boyle, co-founder of Fixie. “Our platform means that you don’t need to have any prior knowledge to prepare your design for 3D printing – opening up the technology to those without the niche skills, time, and resources.”

The platform will be engineered to simplify the architectural 3D printing process by removing the need for time-consuming remodeling of an architect’s design to a 3D printable version. Architects will be able to produce digital 3D designs in hours rather than days, which will subsequently cut costs throughout the supply chain and add value across the construction and built environment sectors.

“This grant award recognizes the potential social and economic impact of Fixie’s platform at a time when architects are rethinking how cities are used and designed,” added Fixie CEO Michelle Greeff. “It’s an endorsement of our vision and the commitment to providing architects with tools to make practical and wider use of emerging technologies.”

Enable granted funding to prove Additive Casting process concept

The second funding grant from Innovate UK was delivered to Enable to embark upon a project to prove the concept of its Additive Casting process, scheduled to run until April 2021.

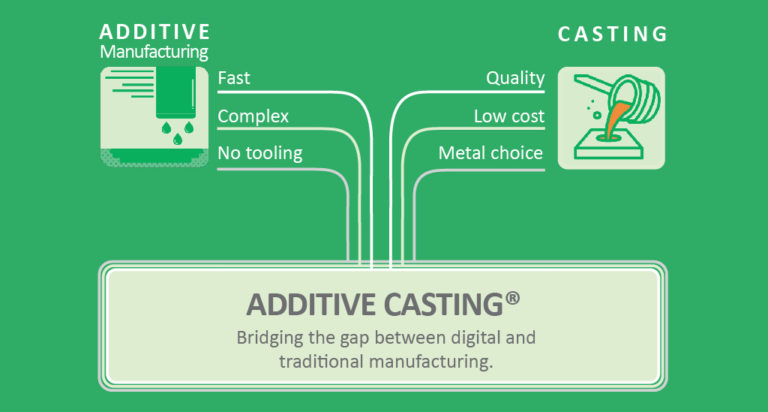

Through its Additive Casting process, Enable essentially offers the material choices of traditional casting, without the limitation and high cost of tooling, as the molds are produced via additive manufacturing.

During the project, the firm will be designing and manufacturing parts via its three available Additive Casting processes, including sandcasting for large parts, investment casting for fine detail, and investment detail for ultra-fine detail. The parts will be produced in four different materials, of which one is magnesium – a material currently unable to be used in direct 3D metal printing processes due to its volatile nature.

Enable’s main goal is to prove Additive Casting as the only manufacturing method currently available on the market that is using additive manufacturing technology to produce highly complex metal parts in practically any size or production volume. In June, the firm announced that it is now able to produce metal parts with its Additive Casting process in more than 130 metals.

“We strongly believe that Additive Casting is a game-changing technology that will help UK companies innovate quicker, make better quality products, and re-shore production for a more sustainable manufacturing model,” said Jon Wright, technical manager at Enable. “In this sense, Additive Casting could play an important role in the UK’s recovery post-Covid and our journey towards a zero-emission economy.

“But for us at Enable this grant also means that there are people and organizations who believe in our technology and are prepared to help bring it to the market successfully. And for this we want to thank Innovate UK.”

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Fixie has secured a £100,000 grant to make 3D printing an accessible tool for architects. Image via Fixie.