While many stories about 3D printing food raise a smile, a fruit simulator may have important applications.

The rate of food waste, even before a product reaches the home, is one of the key factors driving up the cost of fresh fruit and vegetables in stores.

In cold chain supply, fresh produce keeps its quality by following an uninterrupted refrigeration cycle, from production through distribution.

Addressing the current sensor system employed by food suppliers, research led by Empa, the Swiss Federal Laboratories for Materials Science and Technology, suggests a new solution with 3D printed, artificial apples.

From field to refrigerator

In commercial operations, maintaining constant refrigerated conditions is a challenge, particularly as fruit and vegetables often travel long distances from the site of production.

With current systems, sensors are employed to monitor the temperature of a fruit container and the surface of the fruit. Necessarily, these sensors are placed in easy-to-read locations so transporters can quickly identify any changes.

The problem here is that temperature readings do not accurately represent the conditions inside the pulp where a fruit holds most of its nutritional value.

3D printing a fruit spy

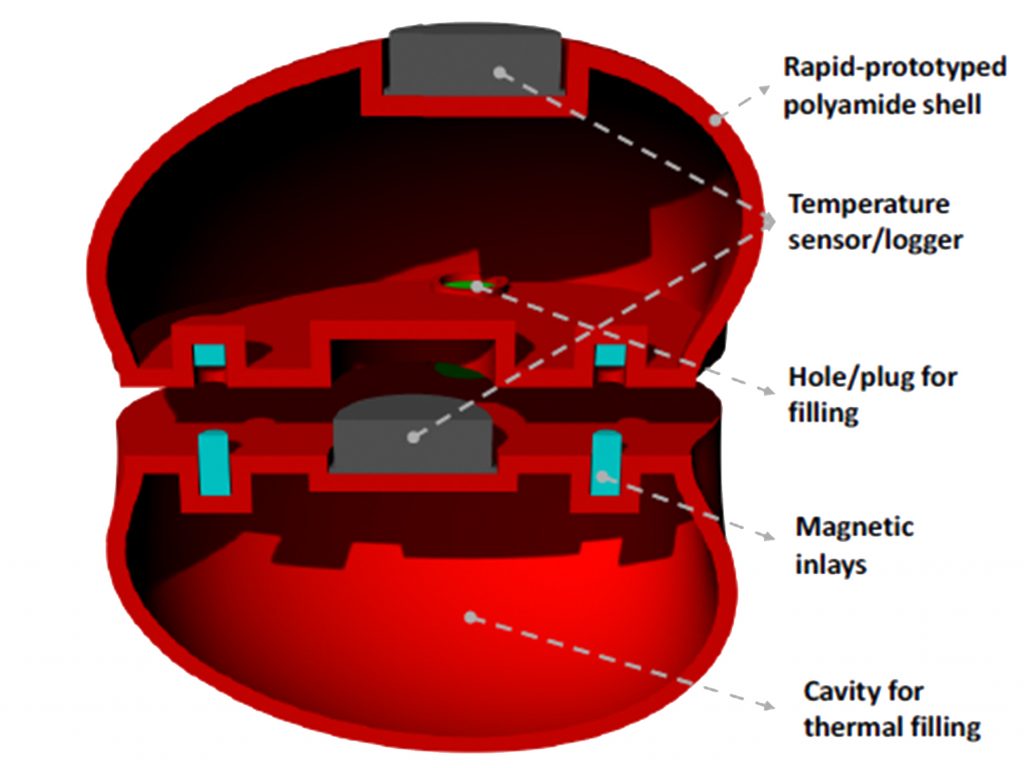

Empa’s artificial fruit devices are designed to mimic the size, shape, and pulpy matter of a real piece of fruit.

After mathematically determining the average size of an apple, a shell for the device is CAD modeled.

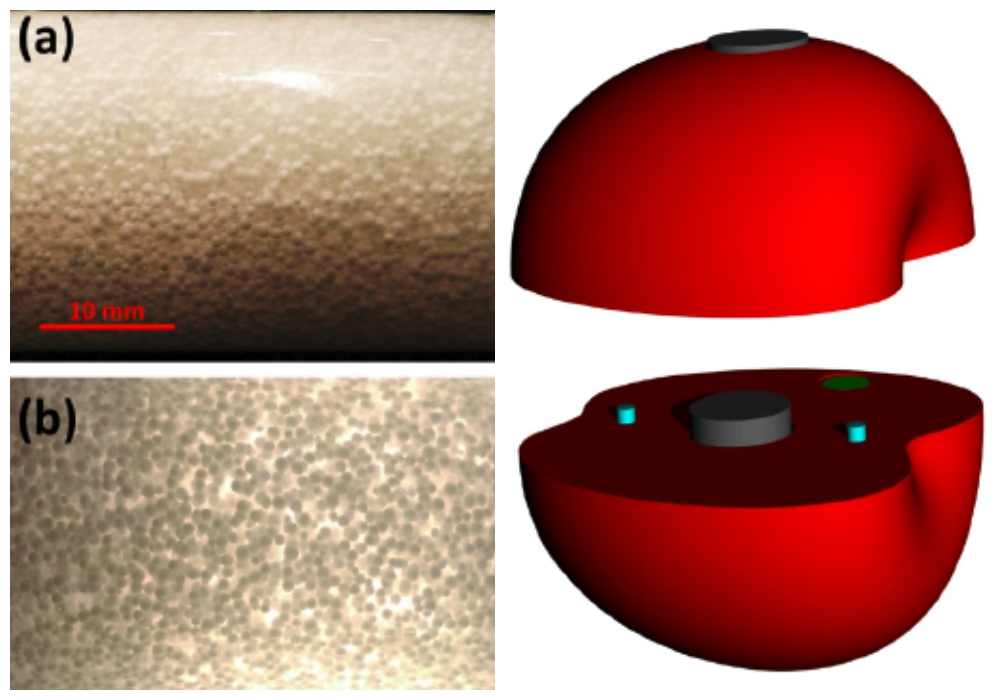

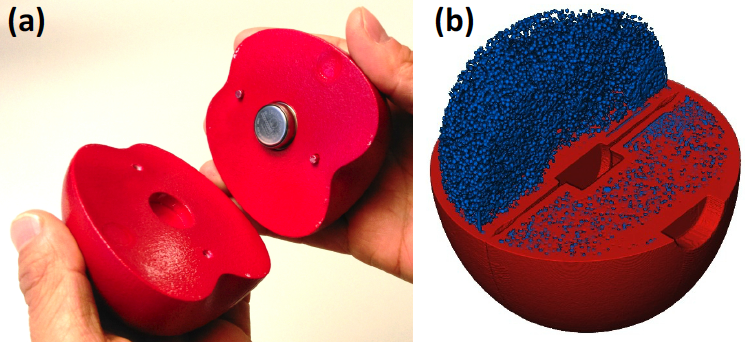

Walls of the shell are tuned to be thin like the skin of the fruit, and hollow chambers are left inside to be filled later with pulp-simulation gel.

The shell is 3D printed in an FDA approved polyamide plastic (PA2200) using selective laser sintering from Materialise.

Consistency of the pulpy gel is determined by taking non-destructive X-ray of the fruit. A sensor is added to the core of the device for recording temperature changes.

By comparing the sensor’s readings to the temperature inside 10 real apples, the team found that the fruit simulator was accurate within 5% of the actual fruit.

The pulp filled fruits were also 16% more accurate than artificial apples containing water.

Apples are not the only fruit

Since creating the apple, Empa has made artificial models for more fruits including bananas, mangos and lemons.

The study, managed by Thijs Defraeye, is now looking for investment to take production to the next level, and even install the devices with wireless connectivity for real-time monitoring,

Working with Defraeye on the project are Wentao Wu, Kevin Prawiranto, Giuseppino Fortunato, Shelley Kemp, Stefan Hartmann, Paul Cronje, Pieter Verboven and Bart Nicolai.

ETH Zurich is also credited as a contributing university, alongside Stellenbosch University in South Africa, the Flanders Centre of Postharvest Technology, and KU Leuven, Belgium.

A paper supporting the research can be accesses online here in the Journal of Food Engineering.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Are you researching 3D printing, or looking for scientists to join your team? Sign up to our 3D printing jobs site now.

Featured image: Empa’s 3D printed apple spy. Photo via Empa Quarterly 57