Today, the University of Strathclyde’s Advanced Forming Research Centre (AFRC), Scotland, and Airbus Defence and Space launched a project that may see additive manufacturing applied to the production of fuel tanks. The project to be undertaken between the two partners aims to reshore space propellant tank manufacture in the UK. Independent welding research organization TWI has been enlisted to help decipher which method is best suited for competitively producing the tanks. Efforts are being funded by the European Space Agency (ESA).

Renato Bellarosa, Head of Tank Products and Research and Technology (R&T) Manager at Airbus DS, comments, “Propellant tanks are key strategic items that we currently must procure from Germany or the United States, and we are working to re-establish the capability to make them in the UK. We had this in the past, but it was lost when the parent company of the firm involved took the production back to Germany.

“We still have independent supply chain processes in the UK, but we need to integrate them to make the tanks. This program with the AFRC fits into a general roadmap that aims to develop this capability.”

Metal forming v superplastic forming v additive manufacturing

The AFRC’s ESA-backed project is focusing on methods capable of producing space propellant tanks as near to net-shape as possible. The idea is that this will reduce machining time and materiel wastage, making for economically competitive production.

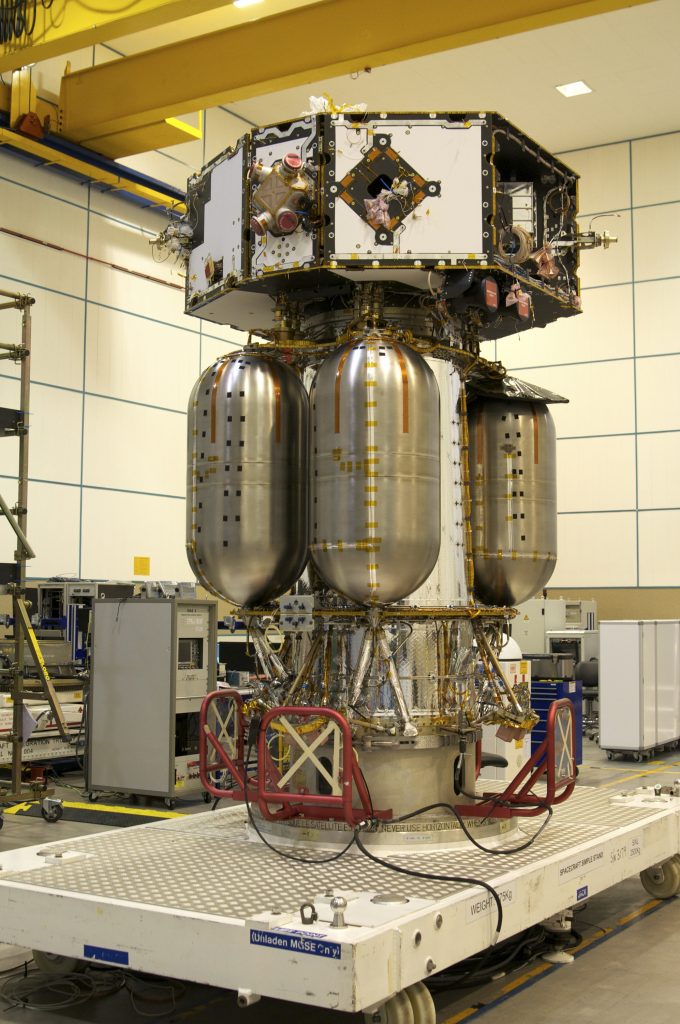

Composed of two hemispheric domes and a cylindrical section, components of the fuel tanks are typically forged, heat treated, machined, then welded together. They are very thin structures, and milling them to the correct thickness creates a substantial amount of waste. At the same time, they must also be strong enough to store propellant under high pressure for up to 25 years, and withstand return from Low Earth Orbit (LEO) back to Earth.

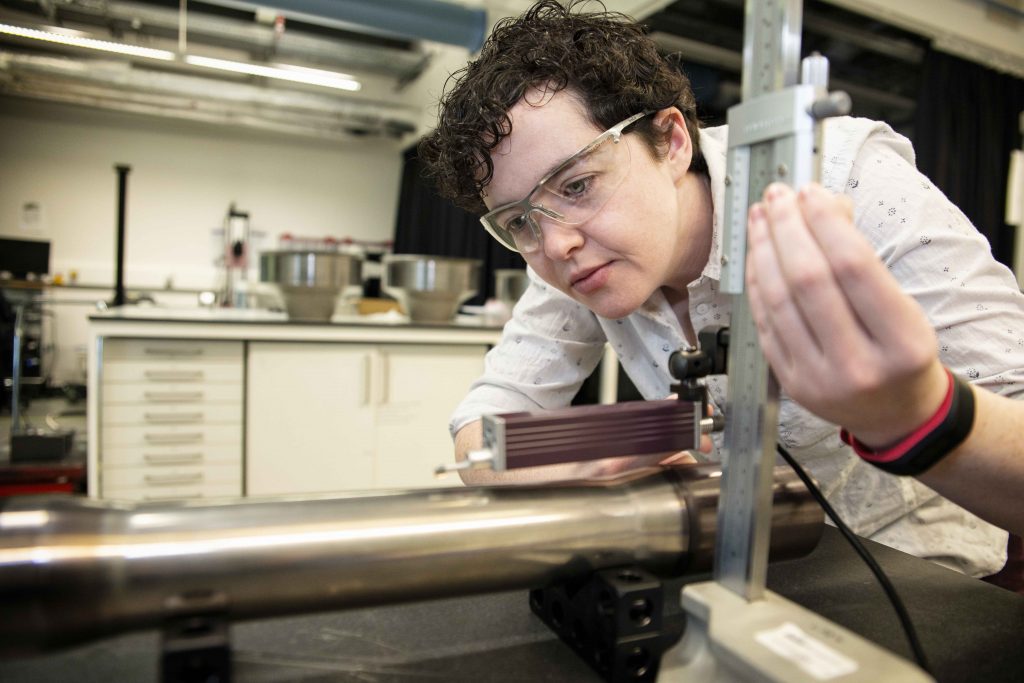

Dr. Jill Miscandlon is fuel tank project lead at the AFRC. “Airbus DS will merge their own research experience with our study and decide on the chosen technique to take forward,” Dr. Miscandlon says, detailing the university’s role in the project. “This could be metal forming, superplastic forming or additive manufacturing processes – all of which would produce the tank parts at close to net shape.”

“Key to the project,” Dr. Miscandlon adds, “is making components in a shorter lead-time and wasting less expensive material, which is essential with titanium alloys costing up to $60 per kilo, depending on alloy type and manufacturing route.”

Benefiting the UK and beyond

The project adds to Scotland’s growing presence in the global space sector. A developing home for the UK’s first spaceport, in Sutherland, the Scottish Highlands, young space exploration businesses are working to create footholds in the country. Early 2019, British spaceflight company Orbex chose to locate its headquartered in Forres, close to the developing spaceport. Sutherland spaceport will also be host to the launch of Rocket Lab Rutherford-fired vehicles. According to the AFRC press release, more small satellites are built in the Scottish port city of Glasgow than anywhere else in Europe.

In addition to the benefits provided to the local economy, and the wider supply chain in the UK, Airbus DS also sees export potential in this program. Bellarosa adds, “We have customers overseas who are big players in satellite manufacture whom we believe would be interested in this new manufacturing approach.”

Concluding comments, Professor Keith Ridgway, Executive Chairman of the AFRC, says, “This is a great project that highlights the benefits of aligning advanced manufacturing research with the UK’s growing space industry.”

“It also taps into the University of Strathclyde’s focus on innovation in space, which is being developed through its Technology and Innovation Centre within the Glasgow City Innovation District, bringing together researchers and high-growth firms with technology and creative start-ups, to work side-by-side.”

For updates on this project and more additive manufacturing news subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows Dr. Jill Miscandlon, fuel tank project lead at the University of Strathclyde’s Advanced Forming Research Centre. Photo via University of Strathclyde