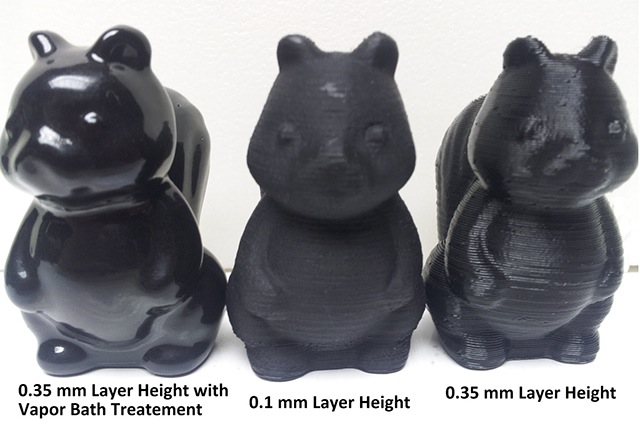

Getting the right finish for your 3D printed object is essential in many cases, especially when you are making gift items or other parts for visible use. Most RepRap users are familiar with treating the printed parts by dipping them in liquid acetone or brushing the acetone onto the part with a slurry mixture, which is often is a cumbersome and messy process. Two enthusiastic makers Austin Wilson and Neil Underwood (Spacexula) have come up with a DIY solution, still using acetone as the treatment, but in vapour form, thereby eliminating the hassle and mess.

Austin’s and Neil’s method is easy on your wallet too and from the images the process is yielding great results. All you need is your RepRap’s heated build plate, which must be able to reach 110˚C, a glass jar, some aluminium foil and a hook to pick up the parts out of the jar.

The pair wrote out simple instructions on how to go about achieving the best results:

“First place your glass jar on the heated build plate and put a liberal amount of Acetone into the bottom of the jar (3-4mm deep). Initially you need to ramp up to 120C, especially if you have a heavy jar. As the jar comes up to temp you will see the meniscus from the edge of the vapor cloud slowly creeping up the jar. Once the vapor is to the top of the jar, turn the plate back down to 90C for the treatment.

Place your sheet of aluminum on your table, and your part on the sheet. Lower the object into the vapor bath (very carefully, you don’t want it falling off). Leave the object in the acetone until you are happy with the amount of smoothing (the object continues to smooth out over the next few hours).

Once the parts are in process you can not touch them at all, the easiest way we have found to get the parts in and out of the jar is to fold aluminum foil into a make shift table and use another smaller sheet of aluminum to act as a base for the part. You can fish the parts out of the jar using a wire coat hanger bent into a make shift flat hook.

When done, carefully remove the object from the bath. If you’re done processing put a lid on the jar loosely and as the vapor cools it will condence back into liquid to be stored in your acetone jar again. Allow the part to sit for another ten minutes, the surface will be very squishy while the residual acetone dries off.”

In the video below you can see the results of the vapour treatment for the 3D printed part and how it is done in practice.

Source: RepRap Blog