3D printer & Laser light source developer 3DM Digital Manufacturing has teased a new technology that enables adopters to tune their Selective Laser Sintering (SLS) 3D printing laser to work with a specific material or application.

Compared to CO2 or fiber beams, 3DM’s customizable laser is said to yield higher-resolution parts with enhanced mechanical properties at reduced lead times. Having fully optimized its technology in R&D settings, the firm is now preparing to bring it to market through the launch of its own proprietary machines. Once released, these are expected to facilitate varied 3D printing use cases where customization is key.

“What makes us unique is that we make our own lasers,” explains Ido Eylon, CEO of 3DM Digital manufacturing. “We don’t use CO2 or fiber lasers or anything like that, we actually produce our own lasers that allow users to aim for a certain wavelength that best matches their plastic material. That’s the difference at the core of our technology.”

SLS laser innovation at 3DM

While 3DM was nominally founded in Israel in 2016, the roots of its technology go back way further with its majority shareholder Dr. Daniel Majer. A graduate of the Weizmann Institute of Science, the 3DM founder has spent 30 years around electro-optic part R&D, while also engaging in laser development, and spending almost a decade working on 3D printing.

Building on Majer’s research, 3DM has now developed a ready-for-market laser that enables the melting of polymer powders at speeds up to ten times faster than existing printing technologies. What’s more, the technology is said to be capable of turning thermoplastics into parts with a resolution much better than current leading printers, in a way that could open up new markets to industrial 3D printing.

In particular, 3DM believes 3D printing can take a larger share of a global polymer manufacturing market that was valued in 2019 at $570 billion. While “insufficient technological innovation” limited industrial 3D printing to “just a few per cent of this market,” the firm says its technology’s low-cost and high scalability has the potential to change this.

Though 3DM initially started out as an incubator company of Terralab Ventures, which still owns around 23% of its shares, it has since been spun out and gone public on the Tel Aviv Stock Exchange. The deal, which saw the business’ IPO wrapped up by June 2021, saw it net around $13 Million, funding it’s putting towards launching its first commercial products.

How does 3DM’s technology work?

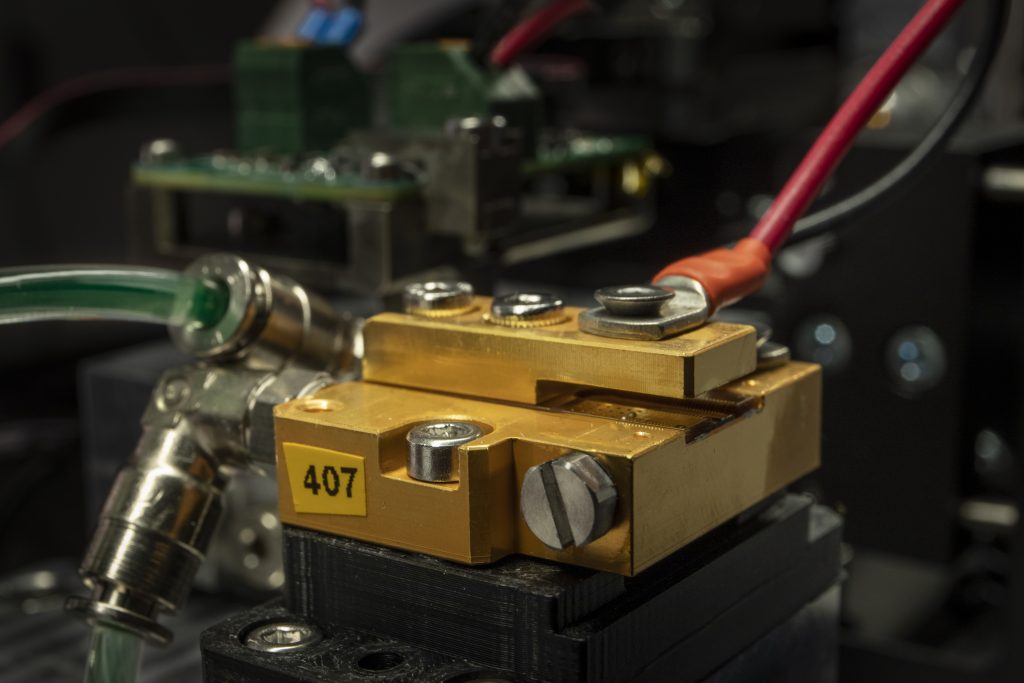

So, how exactly does 3DM’s proprietary laser differ from others on the market? Well, the light source itself is essentially formed by a set of tiny Quantum Cascade Lasers (QCL) that are smaller than a grain of rice. Each of these emits a few watts of energy, the wavelength of which can be customized to suit a given material and the way part layers are arranged.

As opposed to conventional CO2 lasers, which are fixed to a certain wavelength, 3DM says its technology allows for more efficient (and potentially much faster) laser absorption. The company also points out that its laser yields parts with a very high level of surface finish, and how its intended wavelength flexibility makes it compatible with a wider pool of materials.

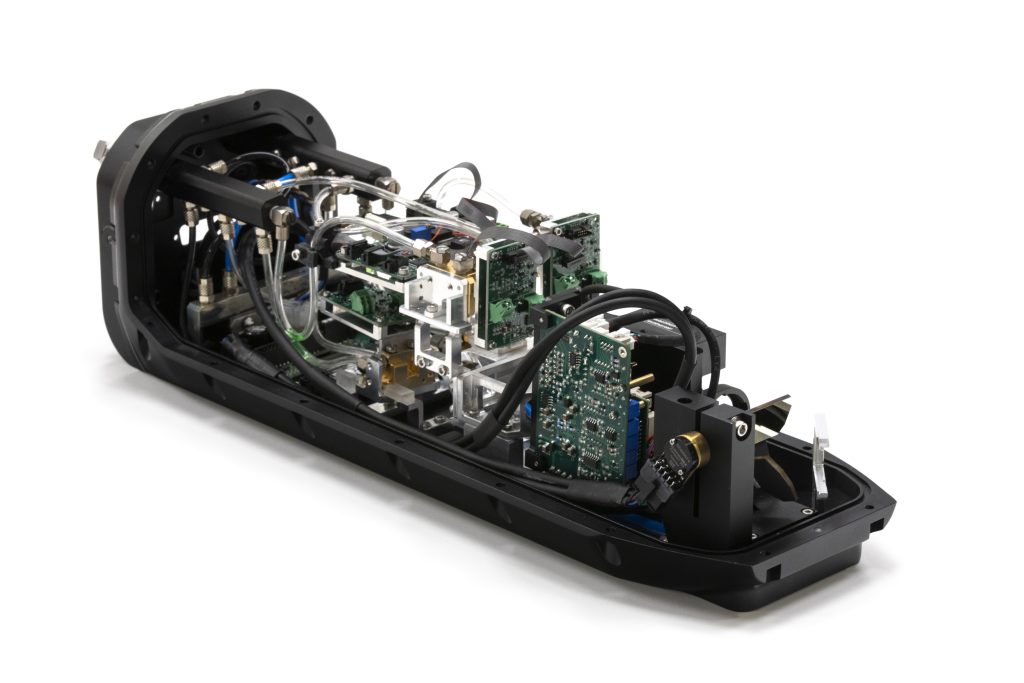

Essentially, 3DM has turned its lasers into a marketable product by affixing them to an assembly composed of a cooling mechanism, driver, and lens to form a laser module. A few of these can then be combined into a beam unit, capable of creating the first multiwavelength spot on a given powder during 3D printing, and enabling the writing of part geometries. In turn, combining four beam units to create a 3DM printhead.

With its first iteration of the product, the firm has combined four beam heads, using a stitching algorithm to ensure there are no gaps between zones. That said, the company says its approach is scalable, with the introduction of more beams likely to increase 3D printing speed. In third-party testing, the technology has even yielded parts with better mechanical properties than those of other leading SLS printers.

Elsewhere, compared to cheaper fiber lasers, 3DM’s technology is capable of hitting higher wavelengths without the need for additives to ensure laser interaction. In fact, the company’s laser can emit at any wavelength in the mid-IR spectrum, in a way that makes it capable of matching any thermoplastic’s absorption properties, and allows adopters to select the most economical feedstock for a given use case.

3DM’s upcoming market offering

Already, 3DM has integrated its laser printheads into four-head prototype R&D systems, and its first-generation machine is now said to be closing in on ‘productization.’ Though the exact specifications of these machines haven’t been public, they’re understood to have printheads mounted to the roof of their build chambers, in a layout that makes cooling more efficient.

As 3DM continues to iterate upon its technology, it aims to identify its potential sustainability and ease-of-post-processing benefits. Application-wise, the company has verified its ability to produce parts from flexible materials like insoles, but it continues to see wide-ranging use cases for its lasers, particularly in areas where mass customization and specialty materials are needed.

Those working on materials or processes that are interested in collaborating on the laser’s benefits and application development are encouraged to contact 3DM Digital Manufacturing here to find out more.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3DM Digital Manufacturing’s laser printhead. Image via 3DM Digital Manufacturing.