This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Raul De Frutos is the Business Developer Manager at AstroPrint. After previous experiences in the finance and metals industry, he found his true calling in 3D Printing.

AstroPrint is delivering cutting-edge operating systems to 3D printer manufacturers at low cost.

3D Printing the Next Five Years by Raul De Frutos, AstroPrint

The next few years are going to be exciting. Desktop 3D printers are going to be in everyone’s home and 3D printer manufacturers will sell units like candies at a kindergarten school. Right?

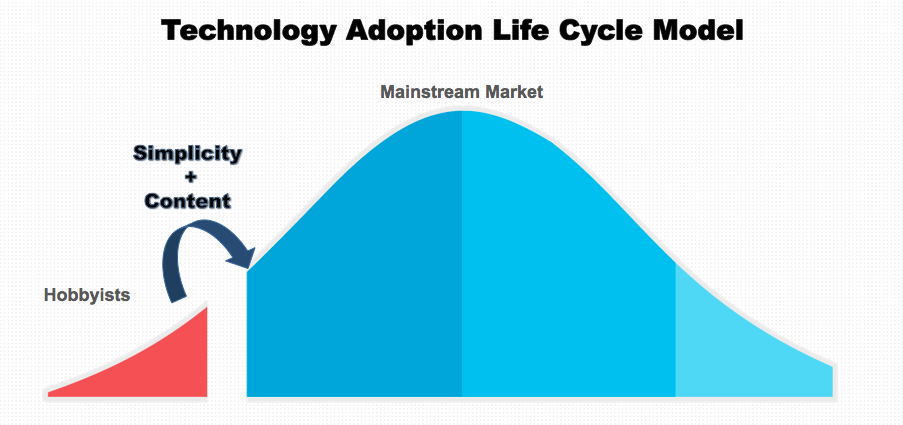

While I’m extremely positive about the future of Desktop 3D printers, the industry needs to first jump the “chasm” that separates the hobbyists and the early majority. Within the next 5 years, manufacturers that don’t make significant changes in their current strategy will miss on the next wave of customers.

What’s stopping desktop 3D printers from mass adoption?

So far, manufacturers have mostly focused on hardware, while software has been left behind. For this reason, we have seen a lot of hardware improvements. Printers are now faster and more reliable. They are also cheap, the Monoprice Mini is a good example of a printer that anyone can afford. Some printers are now beautiful to look at. Our friends at Kodama are putting together an affordable printer that almost looks like an iPhone. I can picture the new Obsidian looking great in anyone’s living room.

If Hardware has improved so much, then why we continue to sell to the hobbyists and not mainstream? The reason is: software has fallen behind.

Most manufacturers are trying to differentiate their products by marketing their printer speed, their new removable plate, a new filament control sensor, interchangeable nozzles, etc. While these hardware improvements are important, they don’t sell to the mainstream market.

Companies that continue to only focus on hardware as their marketing tool will be left behind and lose an incredible opportunity the ride the next wave of mass adoption.

What will make desktop 3D printers shine in the next 5 years?

For the next few years, the key to selling 3D printers is not so much in the HW specs but on showing people what they can do with your printer. To do that, it is crucial to first decrease the learning barrier it takes to get something from digital format to physically in hand. User-friendly software is what allows that.

For the next five years, companies will use software as their marketing tool. Some companies have started to take this initiative. Ultimaker’s new Cura connect is a good example of how a manufacturer uses software to reach more customers, in this case, businesses that manage multiple printers. In my opinion this should be a wake up call for other manufacturers.

Other companies are creating their own ecosystems, like Tumaker. This company aims to simplify the printing experience and use unique content to attract home users into buying their printers. New Matter and XYZ are also good examples.

I believe more companies will jump on this trend and use content to target different niches of people. In addition, selling content or other services is a way for manufacturers to generate more revenue.

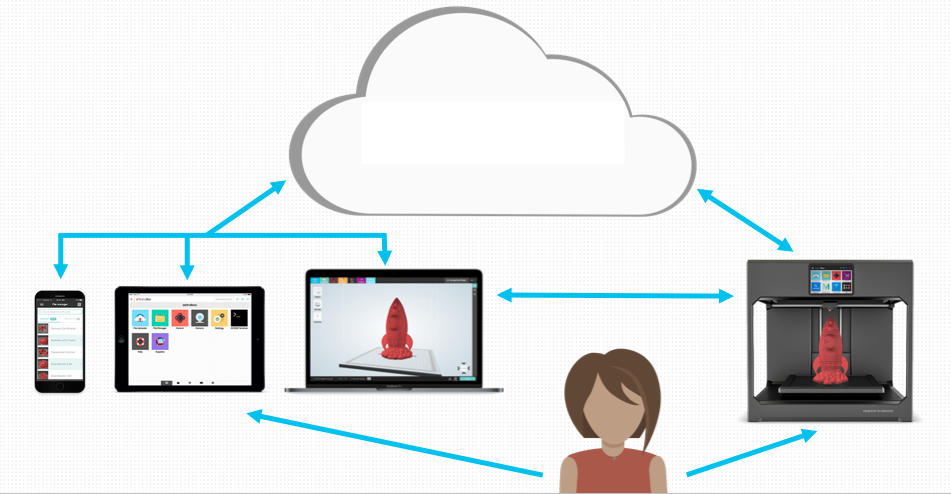

However, for companies to do this, they need a sophisticated and stable cloud infrastructure that allows the printer to be connected to printable content. A user-friendly infrastructure that syncs the printer with multiple devices and that finally ends with the hustle of downloading files and sending them to your printer.

The problem is that manufacturers can’t afford to build and maintain this type of infrastructure on their own. Many companies have tried but they underestimated the costs of building their own software stacks. Tiko is the latest example that proves the need for a standardized platform. Just like how phone manufacturers ship their phones with Android, or how computer manufacturers ship their computers with Microsoft OS, 3D printing manufacturers need a low-cost operating system to ship their printers with it.

AstroPrint is filling this need, providing manufacturers with a low-cost software infrastructure that distributes content to their printers and that they can customize to fit their hardware needs. In the next five years, as 3D printers integrate with a standardized cloud platform, manufacturers will discover new opportunities to partner with developers and content providers to increase sales.

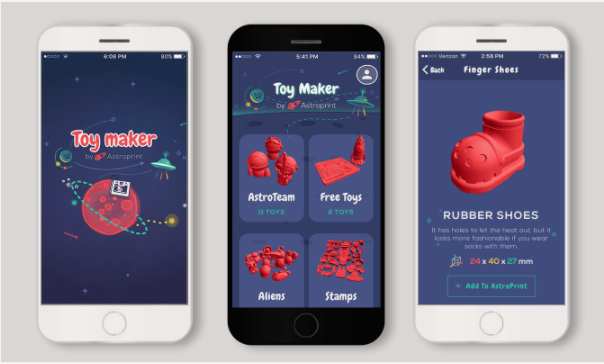

With an infrastructure like this, manufacturers can create applications like the ToyMaker App, to market their printers to parents that want to print toys for their kids. Or create applications with educational content to sell to schools. Or applications for architects, medical, industrial use, the food industry, etc.

3D printing predictions for the next 5 years

While hardware innovations are still needed, software is what will drive mass adoption in the five years.

The days in which 3D printer manufacturers try to build their own software stack from scratch are over. Within five years, 80% of desktop 3D printers will ship with cutting-edge software technology at low cost.

The adoption of a standardized platform is the glue for this still fractionated industry and will encourage software developers, content providers and manufacturers to work together.

Manufacturers need to show people what they can do with their printers. Content sells 3D printers and manufacturers that learn to take advantage will be well positioned to ride the next wave of customers.

Nominations are now open for the 2018 3D Printing Industry Awards. Let us know if AstroPrint gets your nomination for 3D printing software of the year here.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about AstroPrint is available here.