This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

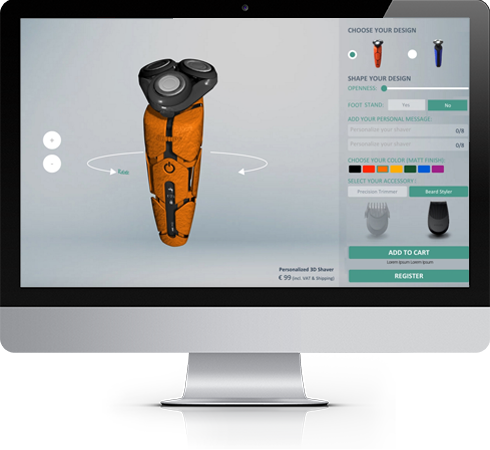

Martijn Joris is the CEO of Twikit NV. Founded in 2012, Twikit is an Antwerp-based start-up. Twikit aims to “guide companies into 3D customization and digital manufacturing.” In addition to their customization software, Twikit also offer consultancy and design services.

3D printing the next 5 years by Martijn Joris, CEO Twikit NV

It’s been more than 10 years since I replied to a job ad which showed a car and spoke about rapid prototyping. Back then, I did not know this technology, but it proved to be the first killer application in the exciting world of 3D printing. I started my career as business developer at Materialise. At the end of 2012 I co-founded Twikit. Our concept originated from a brainstorm how we could enable ‘the fun of 3D creation’ to more people and products.

At the Materialise World Summit this year, it became clear that today there is a lot of energy and momentum towards the full acceptance of 3D printing across many industries. The core message of the event was about connecting the dots and building bridges in order to create the fully digital supply chains needed.

At Twikit, we strongly believe in the great impact the technology will have in the next 5 years, enabling more customization and design freedom. The sweet spot of 3D printing as a production technology was really small 5 years ago and has today dramatically increased in size. This will definitely go on for the next 5 years – with new materials, 3D printers and technologies.

What will we see occurring in the next 5 years?

Applications, applications, applications

As the sweet spot of 3D printing will keep on increasing, many more interesting applications will pop up, driven by market leaders but also new application builders. Young companies can build up advantages based on the technology as it often asks for a radical new approach. Just as all manufacturing 4.0 companies, these builders will need to combine many different skills: product design, software development, hardware knowledge. Multi-disciplinary teams have quickly become the new normal.

The question for product development companies should not be if you can integrate 3D printing, but more when it can be done. Based on the answer, trials can be setup or development started.

5 years ago this meant hearing aids. But in 5 years time it will be your shoes, eyewear, bike helmets, Fitbit jewelry, drones, an unique car interior and so one. The amount of 3D prints will explode.

The 3D trophy factory was the first end-to-end application built by Twikit. We recognized the market was (and is) a really traditional one, but when thinking the idea through it made a lot of sense to combine it with 3D printing. From the start, we didn’t focus on price but on product value. The platform has evolved a lot since the start in 2013.

Mass Customization

Yes, customization or personalisation is and will remain the driver for 3D printed consumer products. No, that does not mean that there will always be an interface where the user has to give input or tweak something. Customization technology can be integrated for much broader applications, it can for example be used pre-create products, create long-tails or take care of the perfect fit.

Smart design and new design drivers

Design for additive manufacturing will mature in the next 5 years and schools will integrate it into their curriculum. Many new design tools will pop up and we look forward to it.

The role of the designer will not fade away. To the contrary, design freedom and making designs for customization or parametrisation requires for good skills. AI and generative design will help.

Because of that, products will look radically different that how we have them in mind today.

Local on demand manufacturing using mass customization and 3D printing will increasingly be a cost effective business model.

3D printing on demand close to the consumer and close to her wishes is good business. The initial investment may be considerable but then it becomes a (near) automated process that can produce goods reliably at scale. It will require a lot of investment but eventually we will get there.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information.

For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about Twikit is available here.