In this edition of the 3D Printing Industry news digest – Sliced, we have news about pre-surgery planning with 3D printing, a self-learning 3D printed robot, and innovative uses of 3D printing in the construction industry. Read on to learn more about updates from 3D Systems, Creaform, U.S. Department of Energy, Copper3D and more.

Expanding 3D printing in Asia

Chemical and materials company Arkema based in France and Hexcel, a composite materials specialist, are collaborating to set up a laboratory in Les Avenieres, France. The lab will be used for the production of carbon-based thermoplastics for the aerospace industry.

Huneed Technologies, a South Korean defense and aerospace, has opened a 3D printing facility called Additive Manufacturing Technology Centre. The Center is based in Incheon and was established with the help of German 3D printer manufacturer, EOS.

Element Materials, a testing and product qualification, has opened a center of excellence in Antwerp for testing 3D printed parts for quality assurance.

Matt Hopkinson, executive vice president of oil and gas and infrastructure at Element, said, “The additive manufacturing industry is thriving and our investment is in direct response to the increased need of our customers for testing of 3D printed materials.”

HBIS Group, a Chinese steel manufacturing corporation, has announced that it will collaborate with the automation company, Siemens. With the help of Siemens, HBIS will develop 3D printing capabilities in China.

Cluster, a job matching site for the Industry 4.0. relevant skills have announced that it has secured $1.9 million in a seed funding round. CEO and founder of Cluster, Kim Taylor said, “Our partners need people with specialized skills like Siemens NX or CATIA”

“Talent needs greater transparency around the skills they need to get hired. Cluster is part of a larger shift towards vertical marketplaces.”

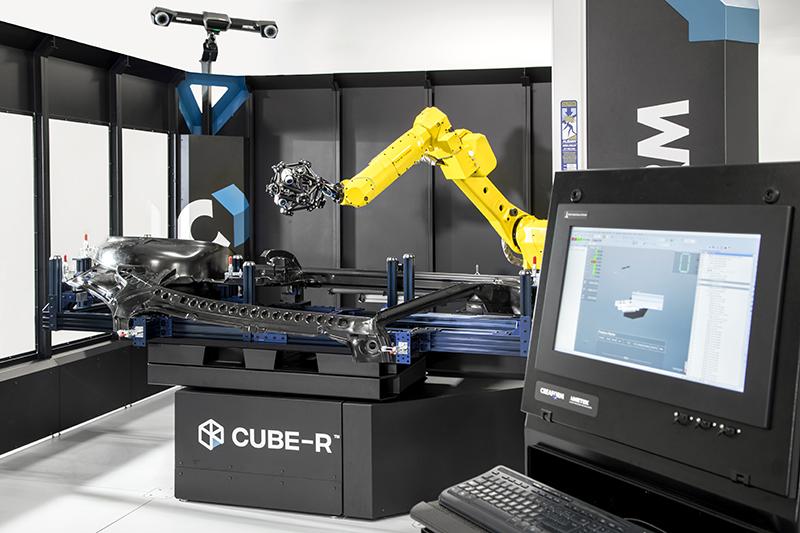

Creaform has set up its automated 3D scanning coordinate measurement machine (CMM), CUBE-R, in Japan at the Narita Service Center.

Pierre-Hugues Allard, Creaform’s Head of Sales for EMEA and APAC, said, “This new quality-control demonstration center is proof of Creaform’s commitment to manufacturers and large-scale Tier 1 supplier in Japan and the entire Asia-Pacific region.”

“With CUBE-R, Asia-based companies that are looking to increase their competitive edge on a global scale can rely on Creaform’s innovative 3D measurement technologies to automate inspections and significantly enhance the quality of their products to meet—if not surpass—international standards.”

Matterport, a London-based 3D scanning and visualisation company, has raised $48 million in a recent funding round. The company received funding from Qualcomm Ventures, Lux Capital, DCM, and other ventures. The money will go towards the development of 3D scanning system Matterport Cloud 3.0.

Challenging innovators

3D Systems has appointed, Malissia Clinton, to its Board of Directors. Clinton is currently employed by the Aerospace Company in Los Angeles, as senior vice president and general counsel.

Vyomesh Joshi, president and chief executive officer, 3D Systems, said, “We are pleased to welcome Malissia to our Board of Directors […] Her acute knowledge of key verticals and extensive background in compliance will play an integral role in helping us to continue to build on our strong operational foundation and advance our leadership position in the additive manufacturing industry.”

In a related news report, 3D Systems’ CFO and EVP, John McMullen, has announced retirement. The decision will come into effect in December.

The U.S. Department of Energy’s (DOE) Office of Energy Efficiency and Renewable Energy (EERE) has announced the winner of the Novel Concepts for Large-scale 3D Printing Challenge. The Challenge is part of the Manufacturing Innovation contest which was initiated by the DOE and Freelancer. The winner of the Novel Concepts is Jason Cotrell, who submitted the proposal for the world’s First Additively Manufactured Support Structure for Wave Energy Converters.

UK-based Manufacturing Technology Associations has launched the Technology, Design and Innovation (TDI) Challenge 2019. The competition calls for students (14-19) to submit their existing coursework project. The challenge does not require students to produce any extracurricular work. Students can win prizes like an iPad or GoPro. And the winning school will receive £2000 for Design and Technology equipment.

Last week, the Fraunhofer IFAM in Dresden inaugurated the Innovation Center Additive Manufacturing (ICAM). The newly established facility houses state-of-the-art 3D printing equipment such as Selective Electron Beam Melting (SEBM) machines, like the Q20plus from ARCAM EBM. Furthermore, in the coming weeks, a system by Xerion, a German electrical furnace, and 3D printer manufacturer, will also be installed.

DyeMansion’s VaporFuse surfacing post-processing technology has now entered the beta-testing stage. Businesses can now register to become part of DyeMansion’s beta-test program.

Altem Technologies Pvt Ltd, an Indian PLM and additive manufacturing company has received the Top Customer Advocacy Business – 2018 Partner Award. The award was given at the Stratasys APJ Annual Partner Meet 2019 in Bangkok. Rajesh Mumbaraddi Director of Altem Technologies said, “Indeed, it is a proud moment for us to be recognized for customer support and more so when we are awarded the best among more than 50 Stratasys partners across Asia-Pacific.”

Building houses

Faro, a Florida-based 3D measurement and imaging company, has announced the release of the FARO Optor Series, a dental impression 3D scanning platform. Thorsten Brecht, Senior Director, 3D Design at Faro, said, “3D dentistry is not the future, it is the present […] Optor delivers the highest level of accuracy, precision, and data completeness so there is no logical reason that the industry should not rush headlong into 3D digitization and away from manual processes.”

“Time is money and, since digitization results in fewer errors and better results in significantly less time, it not only increases customer satisfaction but also significantly enhances bottom lines across the dental industry”.

Planmeca Oy, a Helsinki-based 3D printer manufacturer, has released the Planmeca Creo C5, a chairside 3D printer for dentists.

Jukka Kanerva, Vice President of Planmeca’s Dental Care Units & CAD/CAM division, said, “Chairside 3D printing is the next evolution in one-visit dentistry, allowing practices to offer new same-day services to their patients.”

“Planmeca Creo C5 has been developed specifically with this in mind. It’s an easy and dependable plug-and-print solution with many features that are patent pending and completely new. We truly expect it to be a game changer in the industry.”

Taking 3D printing outdoors, Texas-based construction 3D printing company, ICON, has introduced the Vulcan II. The construction 3D printer is available to pre-order for delivery in 2020. The Vulcan II is capable of 3D printing homes as big as 2,000 square feet. Furthermore, in collaboration with New Story, a charity fighting homelessness, ICON will build a community made of 3D printed houses in Latin America.

At the “Geek Mais Chic” exhibition taking place in Paris’ shopping mall Le Bon Marché visitors can experience how 3D print is revolutionizing the footwear industry. The QUANT-U footwear customization platform of ECCO is on display at the exhibition. The platform can 3D print customized midsoles in silicone rubber, made by Dow.

A Luxembourg-headquartered 3D scanning Artec3D has release Artec Leo. The Leo is an NVIDIA-powered Quad-core 3D scanner. The handheld scanner can collect up to 4 million points per second and has a range between 0.35-1.2 m.

Copper3D, a Chile-based manufacturer of antibacterial materials, has appointed a North American reseller. 3D Universe will be the distributor of Copper3D’s products. 3D Universe stated, “We are very pleased to have a partnership agreement with Copper3D, which is leading ‘The Antibacterial 3D Printing Revolution’. 3D Universe has long been a supporter of the e-NABLE volunteer community, making free 3D printed prosthetic devices for people around the world.”

“With the new materials from Copper3D, we will be able to offer the e-NABLE community an exciting new option for producing high-quality assistive devices.”

Additive Manufacturing Technologies (AMT), a Sheffield-based, post-processing company, has released an automated vapor smoothing system, PostPro3D system. According to the company, the system allows for the production of parts close to injection molding finish.

Authentise, an automation software solution provider for additive manufacturing, has released a mobile web application.

Andre Wegner, CEO of Authentise, said, “Despite the fact that additive devices are nearly entirely digital, the entire process is far from it […] Our software already retrieves data from more additive devices than anybody else, as well as some post-processing tools, but that’s not enough. Manual process steps are tedious enough for operators; reporting their progress shouldn’t be.”

“By releasing this app, we’re simply doing what we always do; focus on making the life of the operator easier. The fact that we’re using the data generated to add further value is just added bonus.”

Applying the knowledge

In a pilot program, Belgium-based Sika Automotive has tested the capabilities of the German RepRap x500 3D Printer. The component printed from polyamide and SikaBaffle, a proprietary elastic material, will be installed on a luxury vehicle.

Institute for Advanced Architecture of Catalonia (IAAC) and World Advanced Saving Project (WASP) showcased a prototype of a 3D printed wall. The current project is part of IAAC Digital Adobe Wall and WASP’s Gaia program, which explores the potential of on-site 3D printing in construction.

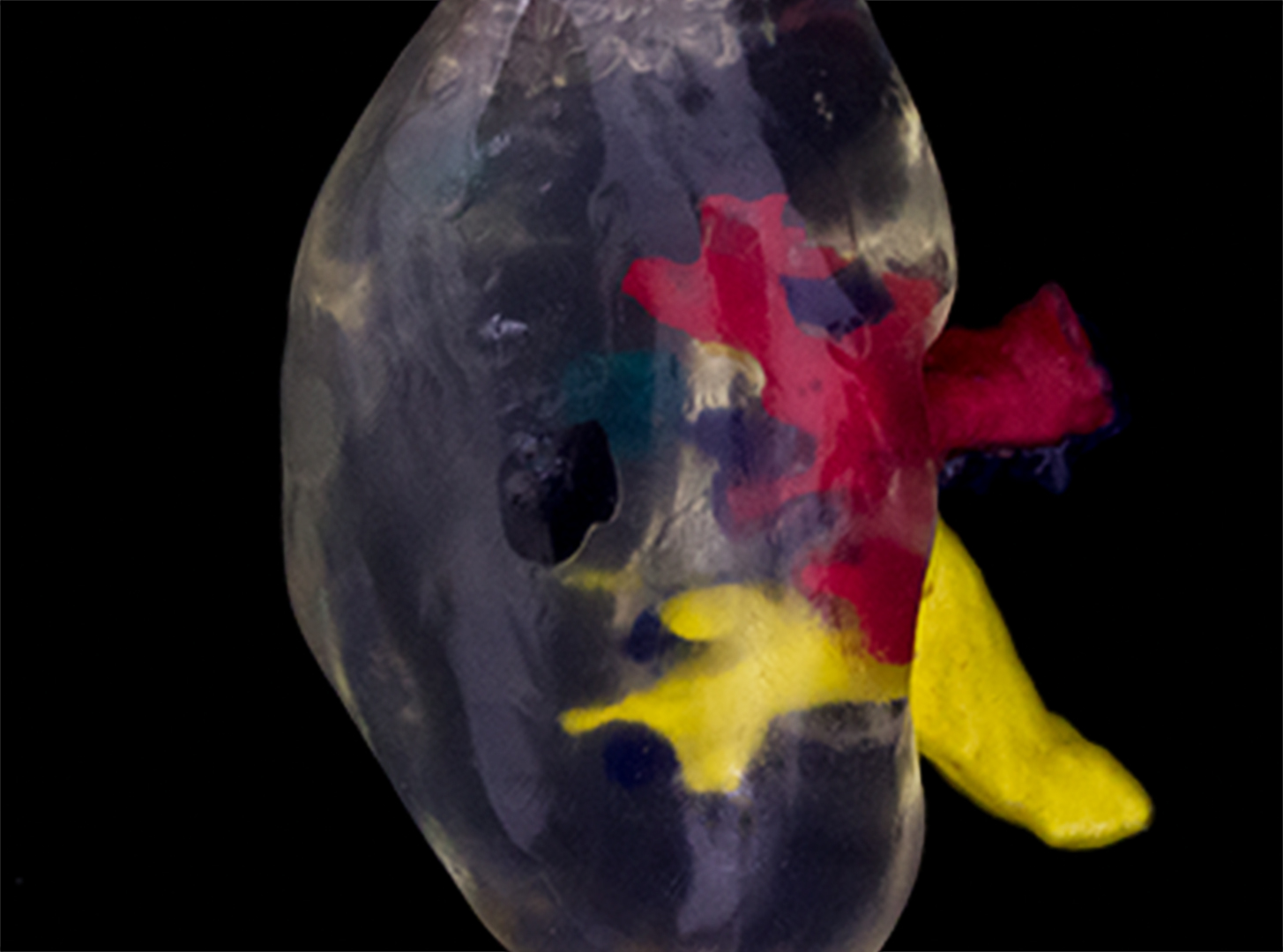

Dr. Tim Brown of Belfast City Hospital collaborated with axial3D to perform a lifesaving kidney surgery. With the help of a 3D printed model of a kidney, Dr. Brown, a transplant surgeon, studied the kidney tumor before operating. This helped the surgeon plan treatment in an interactive way. The tumor was removed, and the kidney was transplanted.

Northwest Nazarene University (NNU) engineering student Ben Campbell, who is also working with NASA to build a 3D printed satellite, is also helping locals with 3D printing. The sophomore student 3D printed an assistive device for an injured ferret belonging to his teacher’s grandson.

Next step forward

CECIMO, a European association representing the common interest of companies in the manufacturing industry, has released the Additive Manufacturing Activities Report 2018.

The University of Southern California researchers have designed a robotic leg which can teach itself to walk based on a positive reinforcement algorithm. The parts of the robotic leg were 3D printed.

Dr. Francisco Valero-Cuevas, professor of Biomedical Engineering and professor of Biokinesiology & Physical Therapy, said, “We want to reverse-engineer brains and bodies and create awesome robots.”

To stay up to date with the latest news in additive manufacturing, subscribe to our 3D printing newsletter, and join us on Facebook and Twitter.

We also have some of the most exciting careers in the industry. Visit our 3D Printing Jobs site to learn more.

Featured image shows with Sliced logo, a graphical rendering of the Vulcan printer and the community of 3D printed houses. Image via ICON.