Multi-material multi-colour output is perhaps the highest aim of desktop 3D printing. There have been a number of recent developments on this front, which include the patented progress made by botObjects, and open source solutions by Amaker and RichRap. Now, the world’s most famed name in desktop 3D printing, MakerBot, can be added to that exclusive list. MakerBot has achieved a patent in multi-material, multi-colour 3D printing. When that technology is applied to any or all of its product range, it could change just about everything…

The Amaker 3D printer crowd funding campaign over on KICKSTARTER is entering its final day, boasting a simple approach to multi-colour 3D printing that clearly achieves results but is largely based on the incremental developments in desktop 3D printing with some additional improvements. Along its other specifications, the Amaker is a worthwhile consideration for anyone looking for a 3D printer at the forefront of Personal Factory technology IMHO. You can check out Davide’s opinion of the Amaker at 3D Printing Industry here.

As the dust settles on the initial reactions to the Amaker, botObjects has almost a year of promotion, accolade and controversy under its belt. Few new 3D printing offerings have been met with quite the level of simultaneous excitement and cynicism as botObjects’ ProDesk3D. On one hand scoring a lead article at Forbes, on the other being met by a wave of concern at various aspects of marketing, customer relations and questioning whether this patented technology really was ready to roll out. We all want them to succeed. We all want this to be the fulfilment of our multicolour dreams. botObjects has come a long way in achieving trust after some quite serious fails.

It is amidst these and other recent developments that we can now add MakerBot to the list. MakerBot’s approach has been somewhat different to botObjects. Whereas botObjects has taken a marketing first approach, seeking to build up excitement and maintain a large public profile for their technology before distribution, the multi-colour breakthrough at MakerBot comes to us in a more Apple-like way: whispers on the internet, rumours in the mill, no fanfare or elaborate promises. At least not yet anyway.

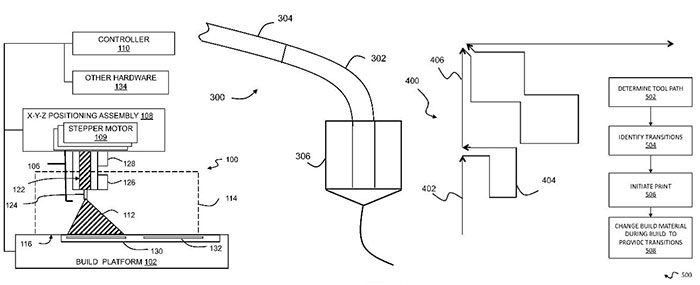

To quote the vital passage from the patent:

’The interplay between the tool path and transitions may be resolved with a variety of techniques. For example, each transition may have a length sufficiently great to permit a first build material (e.g., first color) to evacuate an interior volume of an extruder, as determined empirically or based upon volume displacement or any other suitable technique. As another example, the transition may have a length sufficiently great for a complete change at the nozzle of the extruder from a first color (or build material) to a second color (or build material). This may be particularly useful where volumetric estimates fail to account for residual build material within the extruder that continues to miscolor extruded build material even after extruding a significant multiple of the extruder volume. As noted above, the tool path during these transitions may include an excursion from the object, with the transition occurring during this excursion. This may be an excursion outside an exterior of the object, or along infill structures, or between the infill in interstitial void space. As another example, the tool path may be dynamically monitored with a color camera or the like. With images from this camera, a controller may monitor a color of extrusion from the nozzle and continue to extrude sacrificial material in an excursion from the tool path until the color of extrusion matches the second color of a second build material. Similar measurements such as reflectometry, opacity, or microtexture may also or instead be used, such as for changes from one type of build material to another.’

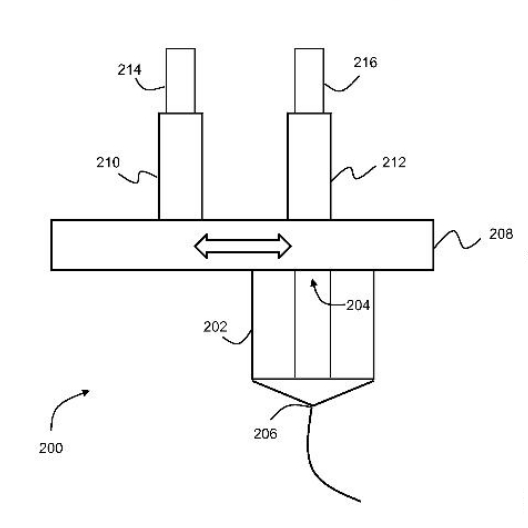

The filament changer has a blade or other cutting edge to cut one material before moving the other into the feed of the extruder. It can switch between two filaments without interrupting a filament supply. What is important here is that the inventors, which include one Nathaniel B. Pettis, got their application in first. Bre Pettis is a fantastic creative thinker and problem solver with a killer instinct for marketing and a huge drive to succeed.

There will be a split in perspectives upon this. The open source and RepRep crowd may roll their eyes. The closed source conventionalists may smile in admiration. Last year my articles at 3D Printing Industry were mainly batting the side of open source, based largely on ideology. Now, though, I find myself more open minded. Intellectual property is on one hand a catalyst for lateral thinking, as others are prompted to think around the patent and come up with a different way to reach the same goal, encouraging diversification of approaches. On the other, technological progress is exponential – as covered in 3D Printing Trends Part 1 – and is now so fast, that a patent registered for twenty years 2014 – 2034 will exclude it’s use by others for an equivalent of very roughly a few centuries at the rate of technological progress 1600 – 1800 for example. The RepRap open source project has fast-forwarded a vast range of 3D printers and 3D printing solutions onto our desk tops. Clearly there are merits in both approaches. The most important thing, this author believes, is respecting the choices of both.

Will Bre Pettis soon have as many 3D printing patents under his belt as the rest of the world’s desktop 3D printing fraternity put together? You can check out Bre’s impressive portfolio of patents here.