In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features an array of new materials, end-to-end software innovation, industry progress on sustainability, online training opportunities and a bold new on-demand manufacturing price promise.

Read on for the most recent updates from Elementum 3D, GEFERTEC, Evolve Additive, Filamentive, Titan Robotics, the AMGTA and more.

6K, Fabrisonic gain top honors

Starting this week with 3D printing awards and accreditations, the sustainability of material specialist 6K‘s UniMelt plasma production system has been recognized as part of the Environment + Energy Leader Awards. Specifically, the firm’s ability to manufacture powders in a more eco-friendly way than conventional technologies allow, has seen it win Top Product of the Year.

Now in its ninth edition, the annual contest is designed to recognize excellence in products and services that provide both energy and environmental benefits, and its organizers say that 6K has had to meet “strict criteria” and an “extremely high bar” set by an expert judging panel, to fend off the competition and win the title.

“UniMelt’s unique ability to leverage scrap material as a feedstock and turn it into high-value powder is just one example of our clean production approach,” said Bruce Bradshaw, CMO of 6K. “UniMelt’s environmentally-friendly process lowers greenhouse gases, uses significantly less energy and produces zero waste water creating a pathway to a circular or sustainable economy.”

“We are honored that the UniMelt platform has been selected as the top product for the Environment + Energy Leader Award.”

In similar news, solid-state metal 3D printing specialist Fabrisonic has gained ISO 9001:2015 certification for the Quality Management System (QMS) behind its Ultrasonic Additive Manufacturing (UAM) process. To reach the international standard, the firm has had to demonstrate that its QMS delivers a high level of client satisfaction, and uses risk-based thinking to snuff-out quality issues early-on.

In striving for ISO recognition, Fabrisonic has also managed to hone its ongoing research efforts, by including its R&D programs in the certification’s scope rather than production. The accreditation itself applies to the company’s UAM-related products, equipment, and R&D service, while the firm expects certified status to positively “impact future growth.”

Business news: Elementum 3D, Evolve Additive, 3DPRINTUK

In the AM business world, U.S. material developer Elementum 3D has announced the adoption of SPEE3D’s patented cold spray metal 3D printing technology. By installing one of the firm’s WarpSPEE3D machines, Elementum 3D now expects to be able to offer clients in the defense, mining, aerospace, automotive and oil & gas industries, a rapid and cost-effective new suite of production services.

“Our revolutionary RAM technology and AM expertise is helping meet the 3D printing industry’s ever-growing demand for a greater selection of printable materials,” said Dr. Jacob Nuechterlein, CEO of Elementum 3D. “We are confident the acquisition of SPEE3D’s technology will be an excellent addition to our current capabilities.”

Over at ex-Stratasys subsidiary Evolve Additive Solutions, the company has shipped its first Scalable Volume Production (SVP) system to a ‘global customer.’ Due to a confidentiality agreement, the client can’t be identified, but the technology is set to be deployed within large-scale, multi-material 3D printing applications.

“Shipment of our first system to a global customer is a significant accomplishment for our organization,” explained Steve Chillscyzn, CEO and Founder of Evolve Additive. “With the proprietary and proven technology that STEP brings, we are confident in our ability to continue to provide solutions to additional clients worldwide.”

Finally, in 3D printing commerce news, British service bureau 3DPRINTUK has rolled-out a “Price Beat Promise,” in which it pledges to beat any part quote offered by its competitors. In practise, those seeking to take advantage of this offer will need to upload proof of their quote to a dedicated online webtool, where the company will review it and make a counter-offer (although shipping is set to be excluded).

“We have always been customer-focused, even with our pricing strategy so that we can truly offer premium and ‘low-cost’ manufacturing solutions,” explained Nick Allen, Managing Director of 3DPRINTUK. “We already offer price breaks based on x/y/z, offset and volume, so offering the Price Beat Promise on like-for-like parts is an obvious move.”

“Above all else, we are known for the quality of parts produced, and this will not in any way be compromised as we beat competitor prices. Best price, best quality. It’s a win win.”

Partnerships with Siemens, GEFERTEC and more

German 3D printer developer GEFERTEC has revealed that it’s collaborating with Siemens to bring NX software to its machines. As part of the firms’ partnership, Siemens’ ‘Multi Axis Deposition’ NX CAM module has been updated to carry out WAAM operations, allowing GEFERTEC users to benefit from a continuous digital process chain.

As one of the first beneficiaries of NX integration, Siemens Energy has been able to optimize its production of WAAM 3D printed components, and begin offering related services to its clients. According to Ole Geisen, the company’s Head of Engineering Services for AM, adopting the software has made a “significant contribution” to “reducing throughput times” within its spare part production process.

“We’re very pleased to be able to offer our customers and the market GEFERTEC WAAM-manufacturing systems with Siemens’ software,” said Tobias Krümberg, CEO of GEFERTEC. “We’re convinced that this collaboration can not only make the potential of WAAM more easily accessible to industrial customers, but enable faster exploration of the technology’s technical and commercial potential.”

Elsewhere, the eco-focused AMGTA 3D printing association has announced the induction of eight new members, bringing its total number to twenty. While ExOne has now joined as a founding member, Forward AM, DyeMansion, Fraunhofer ILT, HP, Rusal America, TRUMPF and 6K will each serve as participating members.

“I’m excited to officially welcome ExOne aboard as a new founding member company of the AMGTA, as well as each of our new participating member organizations,” said Sherry Handel, Executive Director of the AMGTA. “Their dedication to support our trade group’s mission well-positions the AMGTA for continued growth and helps to fund new sustainability research projects.”

“I’m looking forward to working with all of our members as we expand the AMGTA as a key industry resource in advancing sustainability in the AM industry this year and beyond.”

Lighting 3D printing course launched

The U.S-based Rensselaer Polytechnic Institute has begun offering a new online course that’s designed to bring the lighting and additive manufacturing industries closer together. Set to take place over a six-week period, the module will cover the use of 3D printing in the design, development, and manufacturing of lighting components and products.

Specifically, the course is laid out to provide participants with a grounding in how different AM technologies can be applied in lighting, including their strengths, weaknesses and potential applications. While the program comes at a cost of $1,950, members of ASSIST 3D Printing for Lighting can get a 50% discount.

Places are said to be limited, thus applicants will need to provide a 50% deposit up-front. Those interested in enrolling, can now register here.

Markforged, Nexa3D and more release new materials

We finish this week’s roundup with a spate of material launches, including Markforged’s new ‘FR-A’ versions of its Carbon Fibre and Onyx composites. Currently being qualified by the National Center for Advanced Materials Performance (NCAMP), the firm’s materials are designed to meet the Flame, Smoke, and Toxicity (FST) standards required for creating flight-safe interior aircraft parts.

According to Markforged, the high strength-to-weight ratio, surface finish quality and consistency of its composites, make them well-suited to aerospace and defense applications. One of the firm’s clients, Cabin Management Solutions, has already used the materials to develop over 100 end-use parts, and rolled-out a new traceability process that could ease their path to FAA approval in future.

Eco-friendly filament developer Filamentive, meanwhile, has launched a whole new range of materials that are being marketed towards industrial engineering applications. Known as the ‘Filamentive PRO’ line, the company’s high-performance polymers are said to offer a strength-to-weight ratio which surpasses that of most metals, lending them automotive, aerospace and medical potential.

Working with Mitsubishi Chemical and LEHVOSS, Filamentive has put together an initial PRO suite of PEI, PPSU, PEEK, PAHT and PP materials, while manufacturing them in a more eco-friendly way. Each feedstock is set to be spooled on a 100%-recyclable cardboard reel, and it’s anticipated that their inherent hard-wearing qualities will allow any resulting products to last longer, reducing related waste.

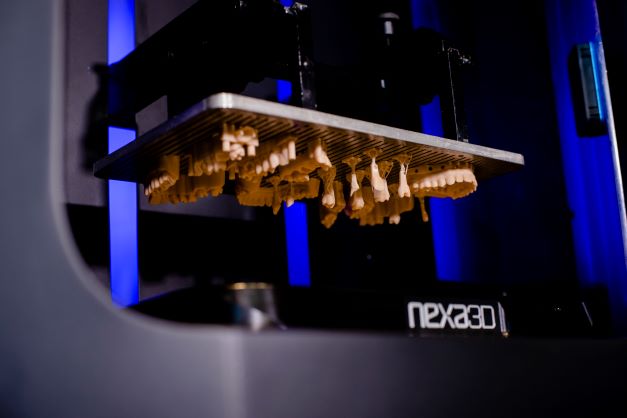

Resin-based 3D printer manufacturer Nexa3D has also added to its material portfolio, partnering with Forward AM to release the new dental-focused ‘xMODEL 2505.’ Featuring a distinctive beige color, the company’s latest polymer is designed to yield highly-accurate orthodontic models and prosthetics, and when used with its NXD 200 3D printer, the resin is said to yield cost savings of up to 85%.

“For dental labs and prosthetics manufacturers that are competing for higher share, based on service levels, fast just got faster thanks to BASF’s new generation of dental materials,” said Kevin McAlea, COO of Nexa3D. “Both companies are committed to democratizing access to additively manufactured dental, industrial and consumer products at scale.”

Lastly, vacuum-bagging and tooling material manufacturer Airtech Advanced Materials Group has partnered with Titan Robotics to make its Dahltram line of resins compatible with Titan’s machines. As part of their collaboration, the firms have worked extensively at Airtech’s HQ, validating and optimizing the material’s properties and performance when used with Atlas 3D printers.

According to Airtech, its materials have proven to be “distinctly suitable for multiple print platforms,” thus the companies intend to continue working together moving forwards, to “develop new materials” and achieve “expanded functionality.”

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of a tray of Nexa3D dental 3D printed prosthetics. Photo via Nexa3D.