In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments and partnerships in the 3D printing sector.

Today’s edition includes several 3D printing partnerships and business deals, four new metal additive manufacturing powders, 3D printed rocket engine components, and a 3D printed cleft lip simulator.

Read on for the most recent updates from the University of Texas at Austin, SolidCAM, Sigma Additive Solutions, Amace Solutions, MeaTech 3D, Umami Meats, ACT Venture Partners, AI Build, Formatec, and more.

New 3D printing partnerships, acquisitions, and investments

Kicking off with the latest business deals in additive manufacturing, 3D printer OEM Desktop Metal has expanded its global partnership with SolidCAM, a provider of CNC software. SolidCAM has been a Desktop Metal sales partner in Germany since 2021, but will now also sell the firm’s metal 3D printing systems in the US, UK, Israel, and India. Additionally, SolidCAM’s CNC + AM Center of Excellence showrooms will showcase Desktop Metal’s Studio System and Shop System machines moving forward.

“The Desktop Metal team is delighted to announce an expansion of our relationship with SolidCAM, a brand that is long trusted by machinists worldwide,” said Ric Fulop, Founder and CEO of Desktop Metal. “This expanded partnership means that more CNC professionals will learn how easy it is to 3D print and sinter complex designs on our Studio System and Shop System metal AM offerings.”

America Makes has also announced a new partnership with 3D printer manufacturer Ultimaker. As part of the deal, Ultimaker will donate more than 20 of its desktop 3D printers to America Makes to be used in middle schools, high schools, and non-profits throughout the US. The goal is to leverage education to grow 3D printing awareness and foster entrepreneurship opportunities for diverse groups and young women across the country.

“We’re passionate about making professional 3D printers, software, materials, and services that are versatile and easy to use for everyone,” said James Butler, VP of Ultimaker, Americas. “With our partnership with America Makes, we aim to add sustainable value across our community and foster an environment of equity that enables the next generation of engineers to leverage 3D printing.”

Elsewhere, Sigma Additive Solutions, a developer of quality assurance software for the 3D printing sector, has announced the latest addition to its Sigma OEM Partner Network: Amace Solutions. The company is the 3D printing arm of Ace Micromatic Group (AMG), the largest machine tool specialist in India. As the latest OEM Partner, Amace will begin offering Sigma’s PrintRite3D monitoring and analytics software in its STLR 3D printers.

Food printing firm MeaTech 3D has signed a memorandum of understanding (MoU) with Umami Meats, a Singaporean firm dedicated to cultured seafood, to jointly develop 3D printed cultured seafood products. The agreement comes under MeaTech’s collaboration strategy and is expected to pave the way for the company’s entry into the Asian market.

Arik Kaufman, MeaTech’s CEO and founder, adds, “We are very pleased about this new agreement which reflects our commercialization strategy of industry collaboration using our unique 3D printing capabilities. We are excited about entering into the seafood sector and believe it will lead us to new market pathways throughout Asia and worldwide.”

ACT Venture Partners announced an investment of $3.2 million in AI Build, a London-based software developer specializing in fully automated toolpath-generation software. The firm’s AiSync platform is designed for industrial additive manufacturing applications, covering every aspect of the 3D printing process such as monitoring, analyzing, and optimizing.

In acquisition news, additively manufactured electronics firm Nano Dimension has signed a definitive agreement to acquire Formatec Holdings for $12.9 million in cash. The deal includes both of the firm’s subsidiaries – Admatec and Formatec Technical Ceramics. Based in the Netherlands, Admatec/Formatec consists of two complementary businesses providing 3D printers and materials for ceramic and metal end-use parts.

Jaco Saurwalt, COO of Admatec/Formatec, will join Nano Dimension as the Head of its Admatec/Formatec Division. He said, “The teams across Admatec and Formatec are excited to become a part of Nano Dimension. We are proud of how we have developed this business and are convinced that we shall be able to expand and accelerate our growth based on our present technology and services.”

Finally, UV hardware developer Visitech has bought Keynote Photonics, an OEM for industrial DLP projection systems. As part of the move, Visitech will also form Visitech Americas, a new subsidiary specifically targeting the additive manufacturing market in North America.

“The Keynote Photonics team accelerated the explosive growth in the additive manufacturing market and our market-leading, high-performance portfolio of scrolling UV and IR printing subsystems,” said Øyvind Tafjord, managing partner of Visitech. “Our teams have worked seamlessly to create new products and to aid customers in getting their products into the market quickly and effectively.”

Four new EOS 3D printing materials

Over in the materials space, leading 3D printer manufacturer EOS has expanded its portfolio with the launch of four new powders for the EOS M 290 system. This includes two new stainless steels – StainlessSteel 254 and StainlessSteel SuperDuplex – as well as the new ToolSteel CM55 and NickelAlloy HAYNES 282.

Sascha Rudolph, SVP BU Metal Materials at EOS, said, “Material development is always driven by customer demand and very often is the result of close customer cooperation. These four new metal materials were designed and optimized specifically to the needs of additive manufacturing. We are increasing application opportunities for demanding industries by bringing AM-tailored alloys to our customers.“

Latest aerospace additive manufacturing news

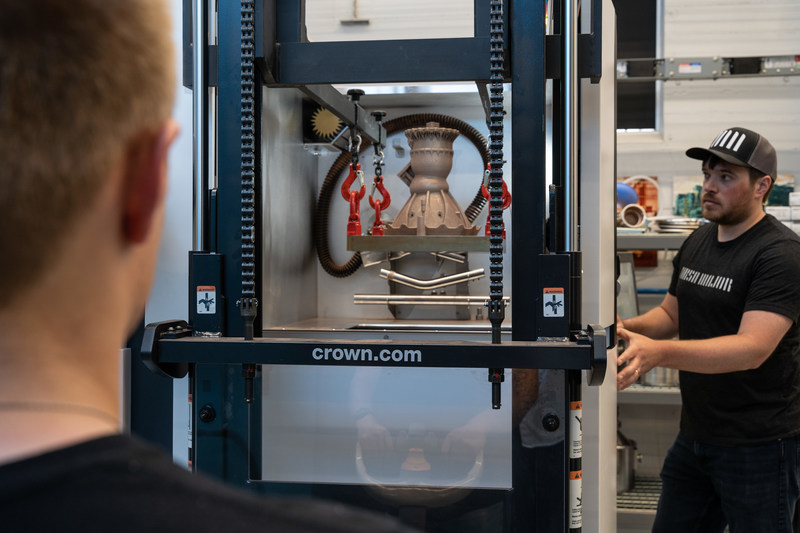

In the aerospace sphere, Ursa Major, a US-based rocket propulsion firm, has created its first set of 3D printed rocket engine combustion chambers. Printed in copper, the parts were made at the company’s additive manufacturing lab in Youngstown, Ohio. The combustion chambers are set to be tested for space and hypersonic applications, and were produced in just one month. Using conventional manufacturing, the same chambers would have required at least six months to manufacture.

“Speed is of the essence when it comes to producing rocket engines right now because lack of propulsion is causing a significant bottleneck in U.S. access to space and hypersonics testing,” said Joe Laurienti, founder and CEO of Ursa Major. “The Ursa Major facility in Youngstown is playing a pivotal role in accelerating our customers’ time to market in both commercial and government sectors.”

Elsewhere, Pratt & Whitney, a Raytheon business, has acquired a Velo3D Sapphire XC 3D printer for the fabrication of end-use jet engine components. This is the first Sapphire machine to be located at a Pratt & Whitney facility, as the firm has exclusively utilized Velo3D’s contract manufacturer network until now. The machine will be evaluated for aerospace applications before proceeding to end-use.

“Metal additive manufacturing can transform aviation and space systems by delivering unprecedented part consolidation, lighter weight components, and more efficient systems,” said Benny Buller, Velo3D’s founder and CEO. “We’re pleased to see Pratt & Whitney move forward with their own Sapphire XC printer. We’re eager to see how they innovate their most mission-critical designs using the end-to-end solution and how the economies of scale of an in-house system help increase addressable use-cases.”

Latest healthcare 3D printing news

In healthcare news, medical device supplier Simulare Medical has debuted its new 3D printed Simulare Bilateral Cleft Lip and Palate Simulator. The cleft training tool aims to give surgeons a realistic practice platform for cleft surgery, one of the most common procedures affecting newborns throughout the world. The device is expected to greatly reduce patient risk, while slashing training costs and improving surgeon confidence.

“Simply put, our Bilateral Simulator saves lives. But not only this, by equipping surgeons from across the globe with training tools such as our Simulator, we can drastically improve children’s lives, giving them the opportunity to thrive. Giving partner surgeons access to this revolutionary technology means that wherever a child lives, they can have access to the same high-quality cleft care and treatment,” said Ian Vallance, Director of Smile Train UK.

In China, 3D printing startup Triastek has begun working with global pharmaceuticals firm Eli Lilly to 3D print drugs to target specific regions of the gastrointestinal tract. The agreement will firstly see Triastek conduct an in-depth study of properties and process parameters to maintain compound stability throughout the 3D printing process. The companies will then identify a unique 3D structure dosage form design, enabling their 3D printed tablets to release drugs in specific parts of the intestines.

Dr. Senping Cheng, founder and CEO of Triastek, adds, “The collaboration between Triastek and Lilly is a great example of applying MED® technology for improving the oral delivery of drugs. We envision that the MED® technology of Triastek can be used to solve the challenges in formulations leading to the development of clinically valuable products for our global partners.”

Researchers at the University of Texas’ Pharmaceutical Engineering and 3D Printing (PharmE3D) Labs have earned a plethora of awards for their research into 3D printed personalized medicine. The PharmE3D Labs were awarded a total of nine accolades, including two Fulbright Scholar Awards, a USAID Fellowship Award, an Egyptian Government Ph.D. Scholarship, and a Science and Engineering Research Board (SERB) Visiting Fellowship.

“This is a magnificent benchmark and I’m elated that we could host these fellowships on multiple innovative research projects,” says Mohammed (MoManiruzzaman, Ph.D., assistant professor of Molecular Pharmaceutics and Drug Delivery and head of PharmE3D Labs. “These competitive accolades are testament to the research efforts we are spearheading in our labs.”

Association for Manufacturing Technology leverages Senvol Database

In Virginia, the Association for Manufacturing Technology (AMT) has licensed data from the Senvol Database, a comprehensive database covering technical data on 3D printing systems and materials. The data will be used to supplement the AMT’s Emerging Technology Research, which provides the 3D printing community with market insights. The Senvol Database is already in use in several sectors such as aerospace, defense, automotive, oil and gas, and consumer goods.

Dayton Horvath, Director of Emerging Technology at AMT, stated, “The Senvol Database is a leading source for data on Additive Manufacturing machines and materials. As we look to roll out our Emerging Technology Research offerings this year, reputable datasets such as the Senvol Database are key to supplementing AMT’s current capabilities and add to the creation of valuable industry insights.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on the 3D printed cleft lip simulator. Photo via Simulare Medical.